Structure of connection joint between local laminated slab and composite wall column

A technology for connecting nodes and laminated boards, which is applied in building structures, buildings, etc., can solve the problems of low processing efficiency of prefabricated components, increase the difficulty of transportation and protection of finished products, etc. The effect of the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

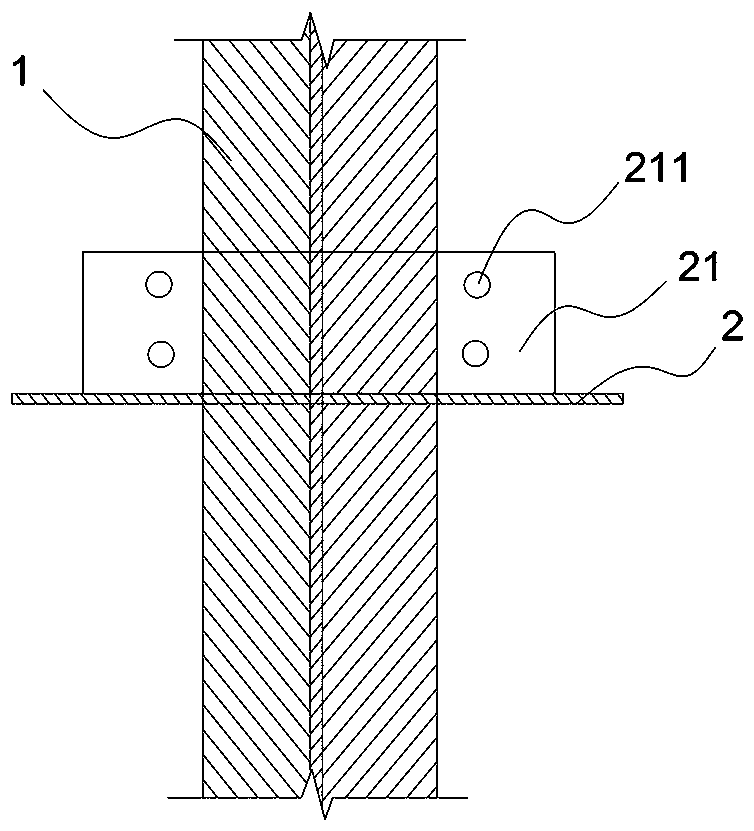

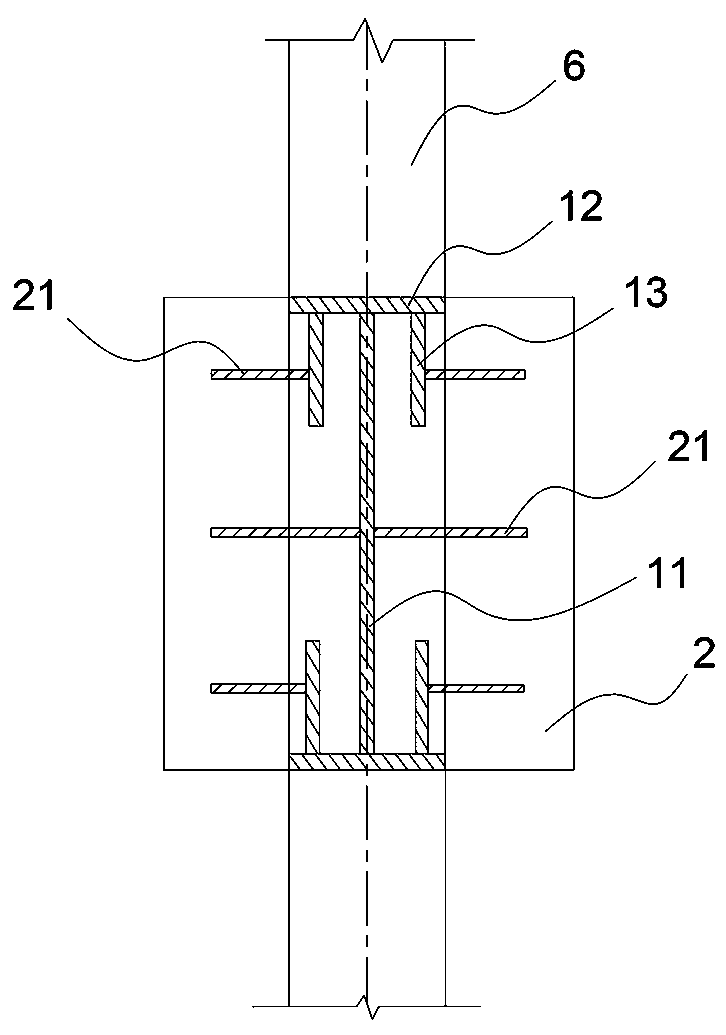

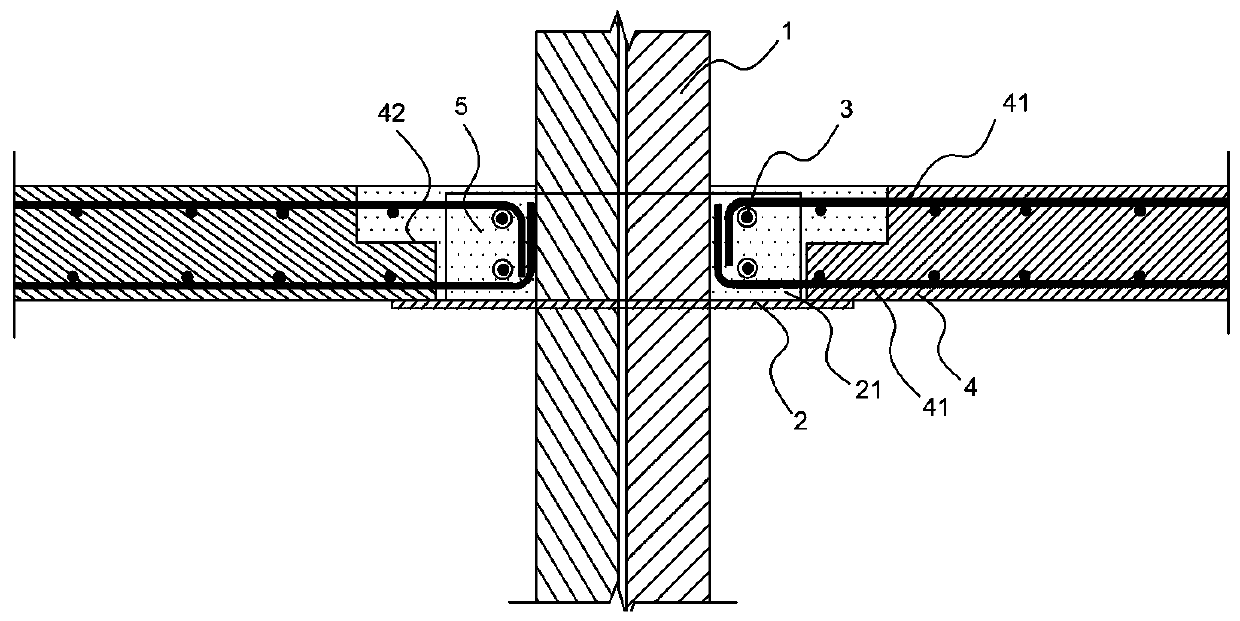

[0021] Such as Figure 1 to Figure 3 The connection node structure between a partially laminated plate and a combined wall column shown includes a combined wall column 1 and a partially laminated plate 4 , and beams 6 are provided on both sides of the combined wall column 1 . The combined wall column 1 is provided with a supporting plate 2 , the supporting plate 2 is provided with a rib 21 , the rib 21 is provided with an opening 211 , and the opening 211 is provided with a rib 3 . The ends of the partial laminated board 4 are erected on the supporting plate 2, and the reinforcing bars 41 on the local laminated board 4 pass through the upper or lower ends of the pierced ribs 3, and bend toward the pierced ribs 3 and the middle part of the combined wall column 1. The joint structure uses the "pin shaft" effect of the rib plate 21 and the penetrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com