Automatic continuous dynamic loading method for testing bearing characteristic of air floating ball bearing

A technology of characteristic testing and dynamic loading, applied in the field of precision measurement, can solve the problems of narrow application range, unstable loading force, inability to achieve continuous loading, etc., to achieve the effect of wide application range and avoid measurement deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

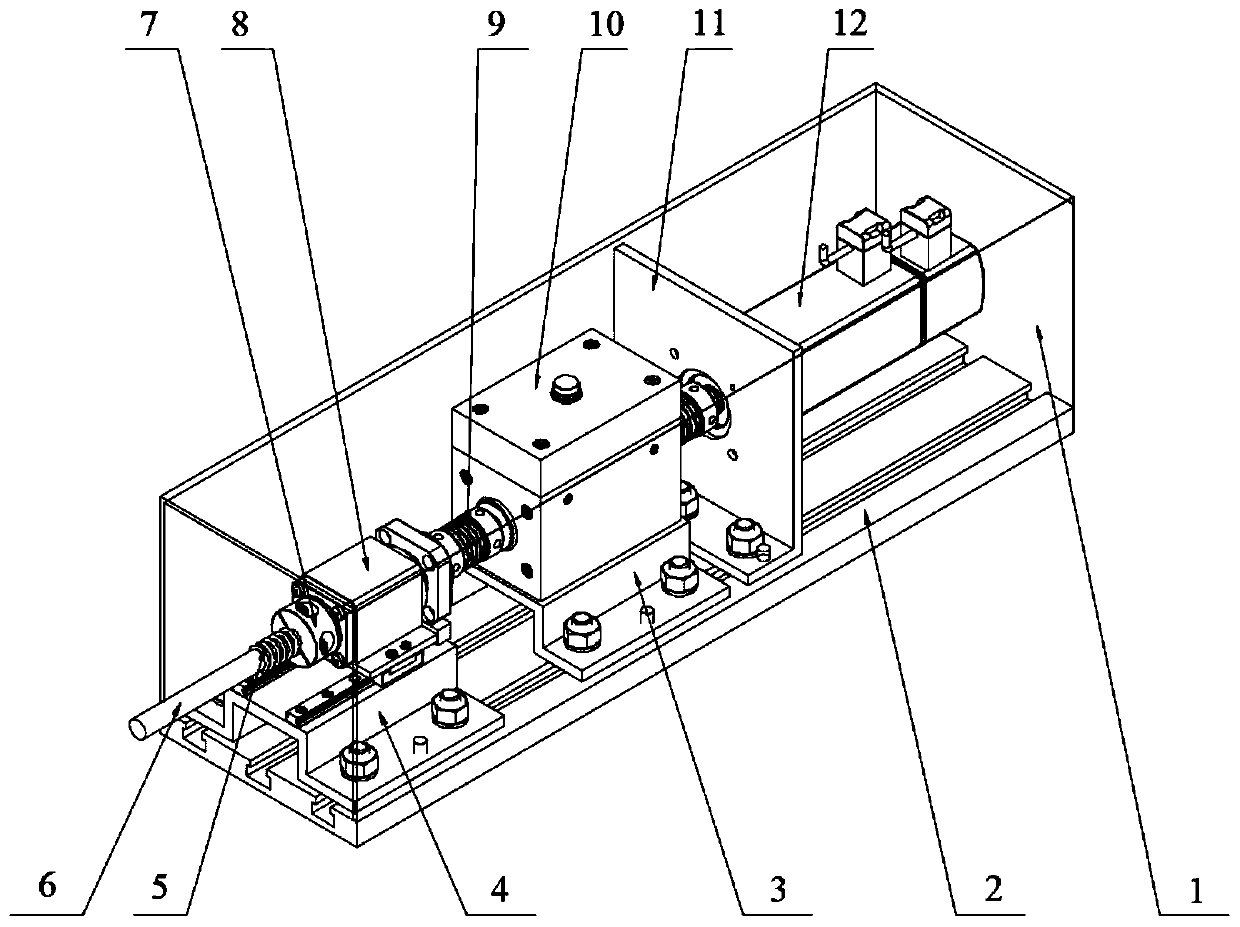

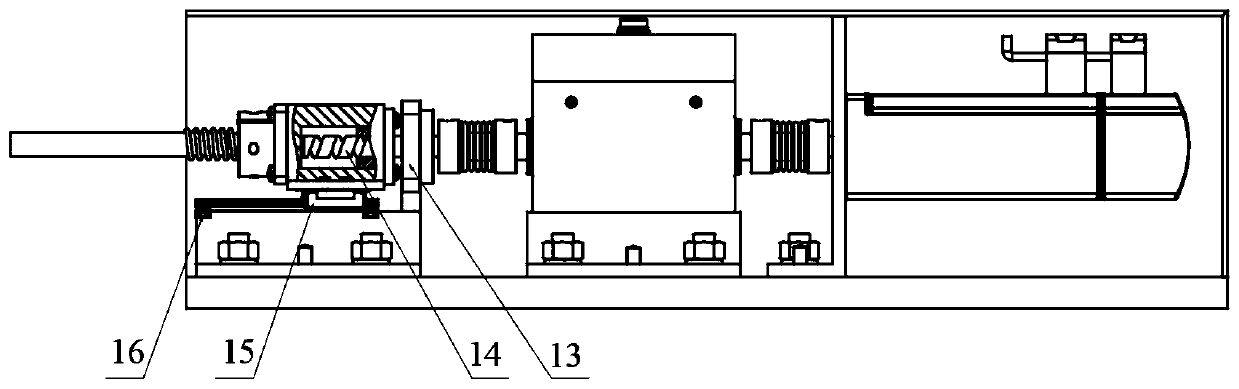

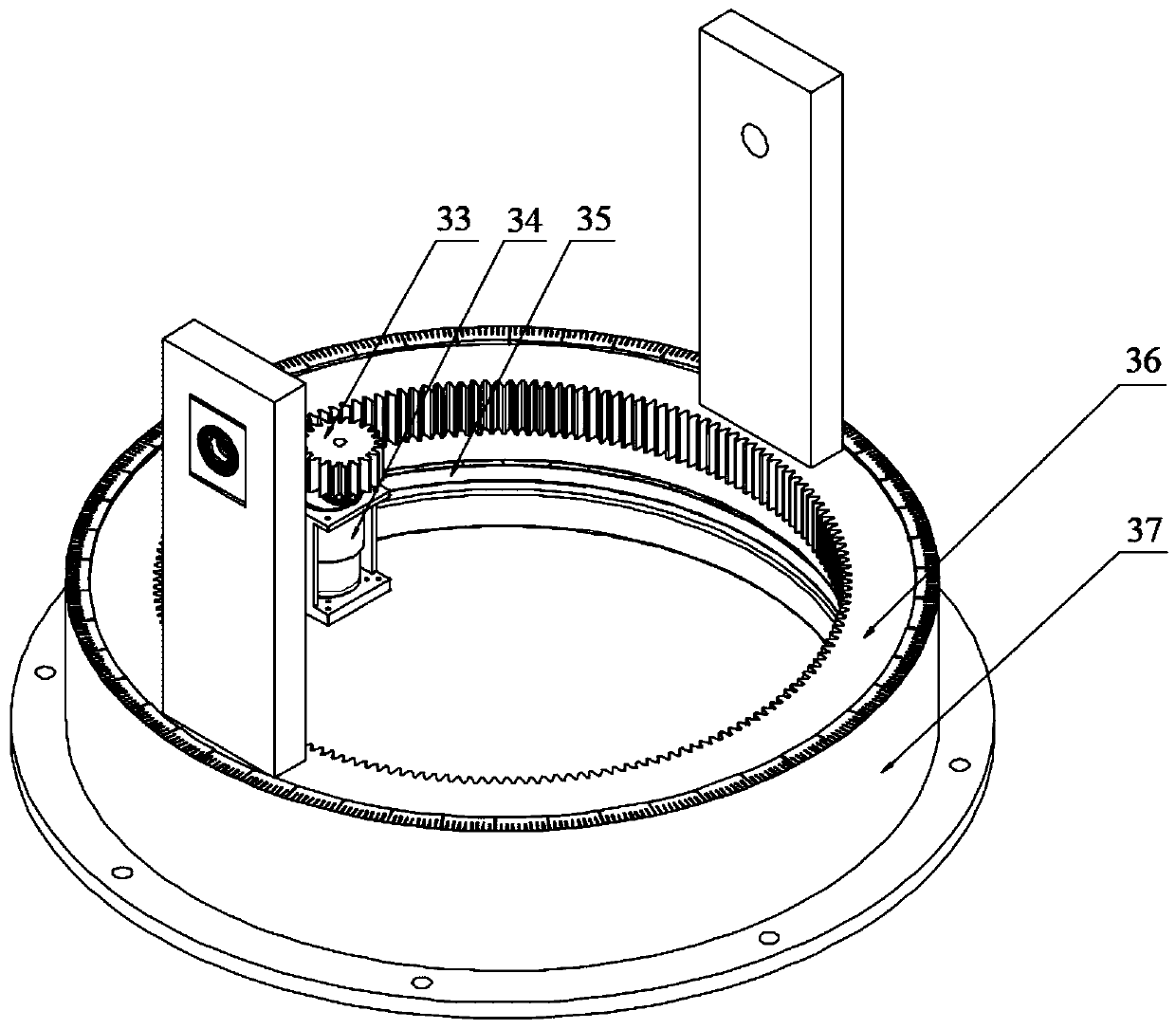

[0039] Such as figure 1 , 2 Shown in and 4, the present invention is used for the automatic continuous dynamic loading method of air bearing characteristic test, the automatic continuous dynamic loading device that adopts, comprises loading mechanism, linear bearing 23, top plate 24, force transmission plate 21, open air Floating ball socket 25, meridional rotation mechanism and weft rotation mechanism; loading mechanism includes base 2, AC servo motor (built-in rotary encoder connected to computer) 12, elastic coupling 9, torque sensor 10, ball screw 14, Linear guide rail 15, limit switch 16, sleeve 8, shaft support 7, spring 5 and dowel 6; base 2 is fixed on the top plate 24; top plate 24 is fixed on the marble platform 32 through the column; the seat of the AC servo motor The body is fixed on the motor support 11, and the motor support 11 is fixed on the base 2; the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com