An electrochemical gas sensor and its diagnostic method

A gas sensor and gas sensing technology, applied in the direction of material electrochemical variables, instruments, measuring electricity, etc., can solve the problems of long detection time of sensor faults, complex control logic and circuits, and inability to quickly judge faults of electrochemical gas sensors, etc. , to achieve the effects of saving microcontroller resources, short fault detection time, and easy judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

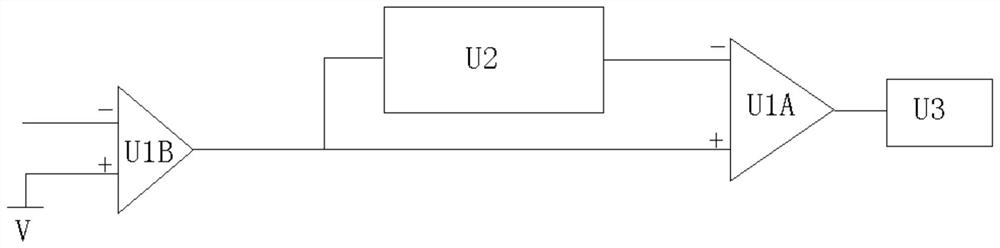

[0043] Such as figure 1 As shown, this embodiment provides an electrochemical gas sensor, which includes an electrochemical gas sensing unit 2, a first operational amplifier 1A and a second operational amplifier 1B;

[0044] One end of the electrochemical gas sensing unit 2 is connected to the inverting input end of the first operational amplifier 1A, and the other end is respectively connected to the positive input end of the first operational amplifier 1A and the output of the second operational amplifier 1B. terminal connection;

[0045] The positive input terminal of the second operational amplifier 1B is connected to a constant voltage;

[0046] The output terminal of the first operational amplifier 1A is connected with the single-chip microcomputer 3 for measuring the output voltage.

[0047] Apply a test signal for a certain period of time to the positive input end of the first operational amplifier 1A, the output voltage of the electrochemical gas sensing unit 2 is o...

Embodiment 2

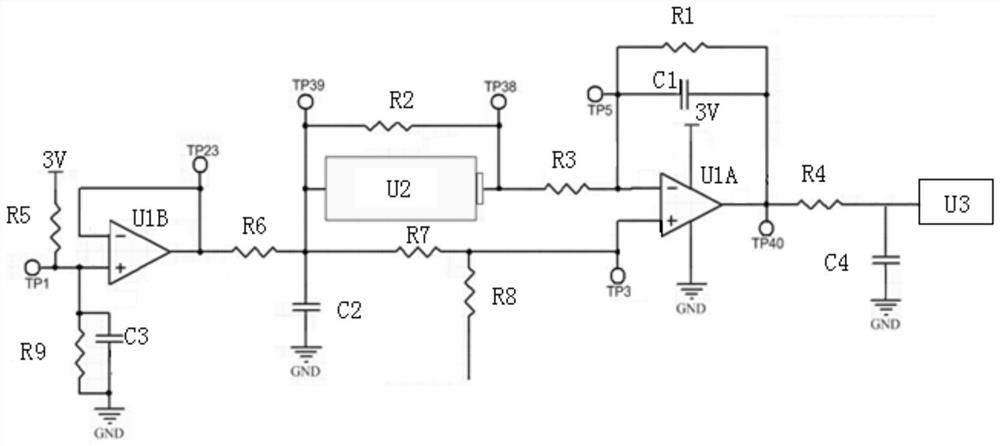

[0049] In order to make those skilled in the art better understand the technical scheme of the present application, a specific embodiment is listed below, such as figure 2 As shown, this embodiment provides an electrochemical gas sensor, which includes an electrochemical gas sensing unit U2, a first operational amplifier U1A and a second operational amplifier U1B;

[0050] One end of the electrochemical gas sensing unit U2 is connected to the inverting input end of the first operational amplifier U1A through the third resistor R3, and the other end is connected to the positive input end of the first operational amplifier U1A through the seventh resistor R7;

[0051] The other end of the electrochemical gas sensing unit U2 is also connected to the output end of the second operational amplifier U1B through the sixth resistor R6.

[0052] The positive input terminal of the first operational amplifier U1A is connected to an eighth resistor R8, and a test signal is applied through...

Embodiment 4

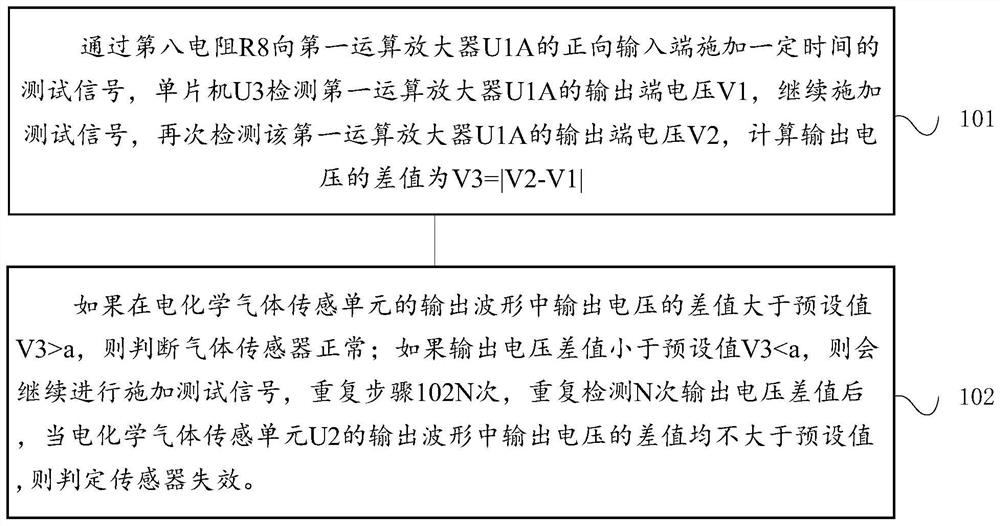

[0063] For the above as figure 2 The electrochemical gas sensor proposed in the second embodiment shown, this embodiment provides a diagnostic method for the electrochemical gas sensor, the method includes the following steps:

[0064] Step 101: Apply a test signal for a certain period of time to the positive input terminal of the first operational amplifier U1A through the eighth resistor R8, the single-chip microcomputer U3 detects the output terminal voltage V1 of the first operational amplifier U1A, continues to apply the test signal, and detects the first operational amplifier U1A again. The output terminal voltage V2 of the operational amplifier U1A, the calculated output voltage difference is V3=|V2-V1|;

[0065] Step 102: If the output voltage difference in the output waveform of the electrochemical gas sensing unit is greater than the preset value V3>a, it is judged that the gas sensor is normal; if the output voltage difference is less than the preset value V3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com