A kind of lithium ion battery negative electrode binder and the preparation method of lithium ion battery negative electrode

A lithium-ion battery and binder technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of electrode loss of conductive network, material pulverization, and inability to effectively alleviate the volume effect, and achieve broad application prospects , control the volume effect, and improve the effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

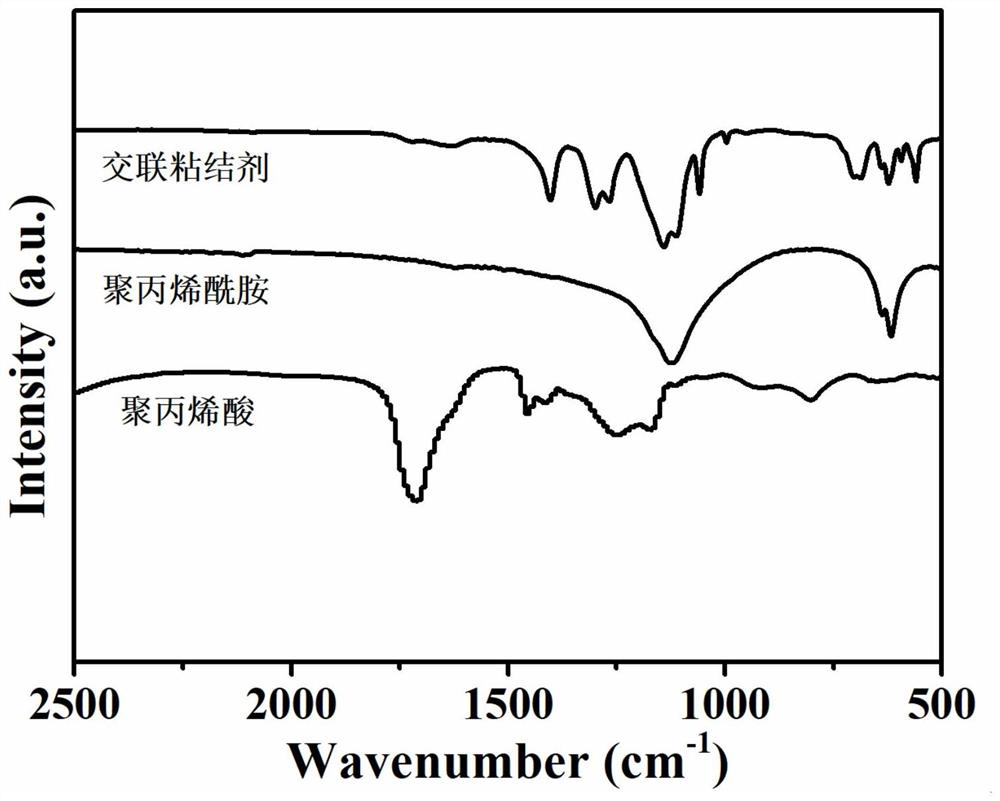

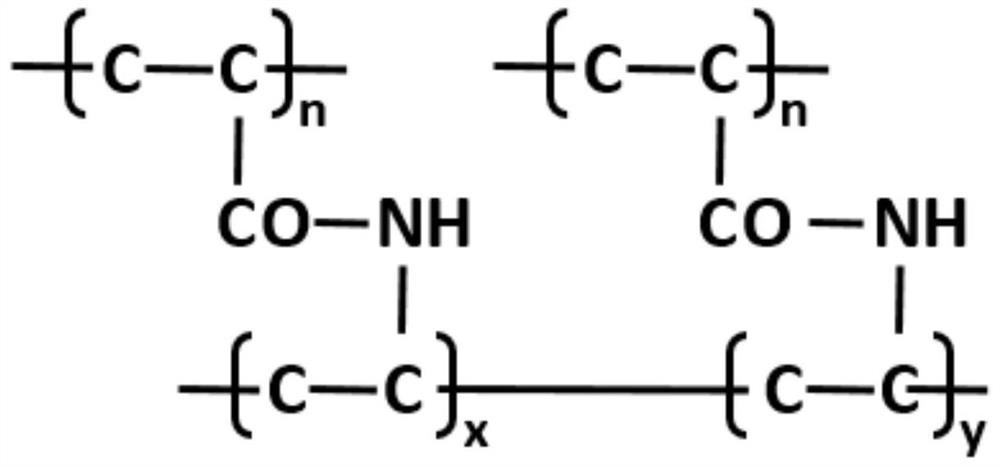

[0025] A method for preparing a cross-linked lithium ion battery silicon negative electrode binder, comprising the steps of:

[0026] (1) Mix polyacrylamide and polyacrylic acid according to the mass fraction ratio of 3:7, dissolve in 100ml deionized water, and use magnetic stirring to prepare a uniform solution.

[0027] (2) Dissolve 0.2g EDC and 0.3g NHS in 10ml deionized water, add to the mixed solution obtained in (1) after the dissolution is complete, and magnetically stir for 10 hours at room temperature to obtain a viscous homogeneous solution.

[0028] (3) The viscous solution obtained in step (4) was dialyzed twice with deionized water. Then place it in the freezer layer of the refrigerator to freeze until it is solidified, and then put it into a freeze dryer for vacuum freeze-drying to obtain a cross-linked binder.

[0029] (4) Dissolve 0.3g of the cross-linked binder obtained in step (3) in 2ml of deionized water to obtain a uniform binder solution, then weigh 0.3g...

Embodiment 2

[0032] (1) Mix polyacrylamide and polyacrylic acid evenly according to the mass fraction ratio of 4:6, dissolve in 100ml deionized water, and use magnetic stirring to prepare a uniform solution.

[0033] (2) Dissolve 0.2g EDC and 0.3g NHS in 10ml deionized water, add to the mixed solution obtained in (1) after the dissolution is complete, and magnetically stir for 10 hours at room temperature to obtain a viscous homogeneous solution.

[0034] (3) The viscous solution obtained in step (4) was dialyzed twice with deionized water. Then place it in the freezer layer of the refrigerator to freeze until it is solidified, and then put it into a freeze dryer for vacuum freeze-drying to obtain a cross-linked binder.

[0035] (4) Dissolve 0.3g of the cross-linked binder obtained in step (3) in 2ml of deionized water to obtain a uniform binder solution, then weigh 0.3g of silicon powder and 0.1g of conductive agent super P and binder The solution is mixed evenly to obtain electrode slur...

Embodiment 3

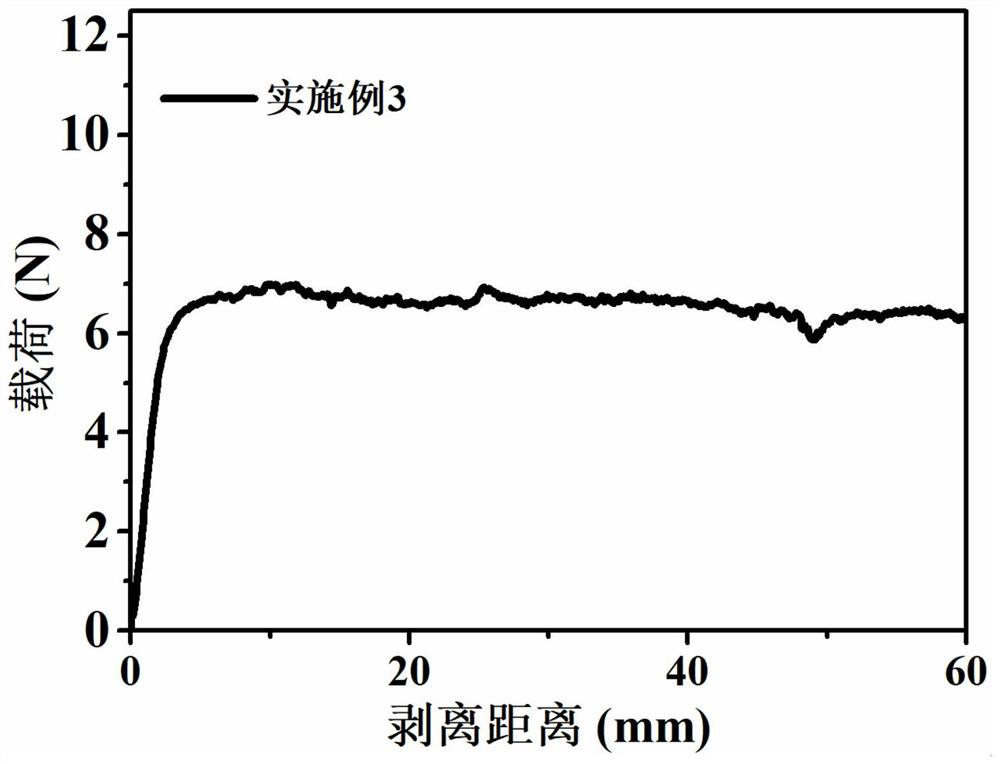

[0038] (1) Mix polyacrylamide and polyacrylic acid according to the mass fraction ratio of 5:5, dissolve in 100ml deionized water, and use magnetic stirring to prepare a uniform solution.

[0039] (2) Dissolve 0.2g EDC and 0.3g NHS in 10ml deionized water, add to the mixed solution obtained in (1) after the dissolution is complete, and magnetically stir for 10 hours at room temperature to obtain a viscous homogeneous solution.

[0040] (3) The viscous solution obtained in step (4) was dialyzed twice with deionized water. Then place it in the freezer layer of the refrigerator to freeze until it is solidified, and then put it into a freeze dryer for vacuum freeze-drying to obtain a cross-linked binder.

[0041] (4) Dissolve 0.3g of the cross-linked binder obtained in step (3) in 2ml of deionized water to obtain a uniform binder solution, then weigh 0.3g of silicon powder and 0.1g of conductive agent super P and binder The solution is mixed evenly to obtain electrode slurry. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com