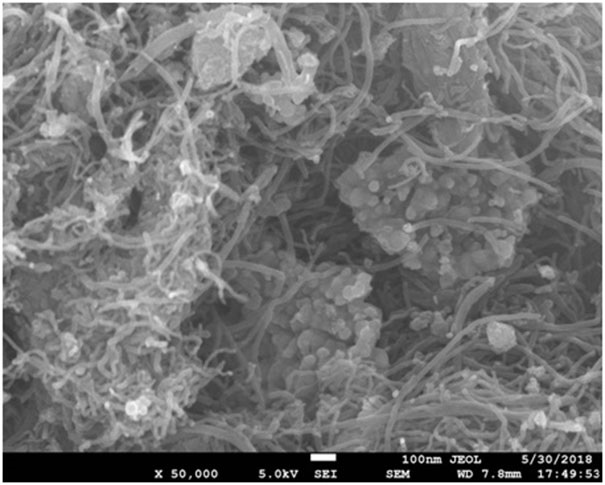

Synthesis method and application of fluorine-doped carbon-coated silica nanoparticles@carbon nanotube composites

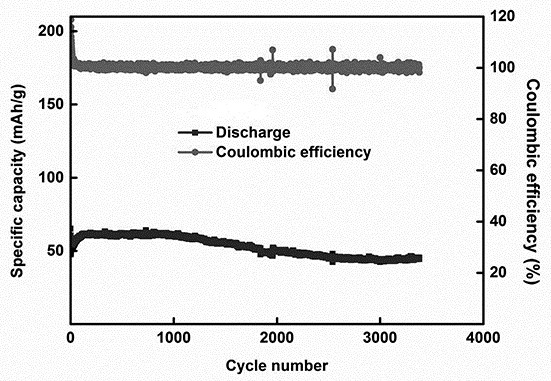

A technology of carbon-coated silicon oxide and carbon nanotubes, which is applied in the field of lithium-ion capacitors, can solve the problems of low conductivity, capacity fading, poor conductivity, etc., achieve simple synthesis methods, improve charge and discharge performance, and improve electrochemical performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for synthesizing a fluorine-doped carbon-coated silicon oxide nanoparticle@carbon nanotube composite material, comprising the following steps:

[0029] Step a). N-methylpyrrolidone is mixed with a perfluorosulfonic acid resin dispersion whose pH has been adjusted to neutral, and distilled to obtain a mixed dispersion of perfluorosulfonic acid resin / N-methylpyrrolidone;

[0030] Step b). Mix multi-walled carbon nanotubes with concentrated nitric acid, reflux at 110-130° C. for 6-24 hours, naturally cool to room temperature, filter and wash with water, add ethanol / water solution after drying, and add the obtained product in step a) after ultrasonication for 1 hour Perfluorosulfonic acid resin / N-methylpyrrolidone mixed dispersion, after mixing evenly, add tetrapropoxysilane, and stir evenly to obtain a mixed solution;

[0031] Step c). Add concentrated hydrochloric acid to the mixture obtained in step b), stir at room temperature for 30 to 48 hours, then filter wi...

Embodiment 1

[0039] Step a). Add 1 mol / L KOH ethanol solution dropwise to an appropriate amount of 13.8% perfluorosulfonic acid resin ethanol dispersion to adjust the pH value of the resin dispersion to neutral. Mix N-methylpyrrolidone with a volume ratio of 1:1 with the perfluorosulfonic acid resin dispersion whose pH has been adjusted to neutral, and distill at 150°C to obtain a mixed dispersion of perfluorosulfonic acid resin / N-methylpyrrolidone ;

[0040] Step b). Mix the multi-walled carbon nanotubes with concentrated nitric acid, reflux at 130°C for 24 hours, cool to room temperature naturally, filter and wash with water until the pH is between 6 and 7, after drying, add 7:1 volume ratio Ethanol / water solution, after ultrasonication for 1 hour, add the perfluorosulfonic acid resin / N-methylpyrrolidone mixed dispersion obtained in step a), mix well, then add 1g of tetrapropoxysilane, stir well to obtain a mixed solution;

[0041] Step c). Add 60 grams of 37% concentrated hydrochloric ...

Embodiment 2

[0046] Step a). Add 1 mol / L KOH ethanol solution dropwise to an appropriate amount of 13.8% perfluorosulfonic acid resin ethanol dispersion to adjust the pH value of the resin dispersion to neutral. Mix N-methylpyrrolidone with a volume ratio of 1.5:1 and the perfluorosulfonic acid resin dispersion whose pH has been adjusted to neutral, and distill at 150°C to obtain a mixed dispersion of perfluorosulfonic acid resin / N-methylpyrrolidone ;

[0047] Step b). Mix the multi-walled carbon nanotubes with concentrated nitric acid, reflux at 130°C for 24 hours, cool to room temperature naturally, filter and wash with water until the pH is between 6 and 7, after drying, add 7:1 volume ratio Ethanol / water solution, after ultrasonication for 1 hour, add the perfluorosulfonic acid resin / N-methylpyrrolidone mixed dispersion obtained in step a), mix well, then add 7g of tetrapropoxysilane, stir well to obtain a mixed solution;

[0048] Step c). Add 80 grams of 37% concentrated hydrochloric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com