Banana tree trunk cutter

A cutter and tree trunk technology, applied in cutting tools, cutting equipment, gardening, etc., can solve problems such as affecting banana trees and inconvenient cutting, and achieve the effects of being beneficial to safety, reducing burden, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

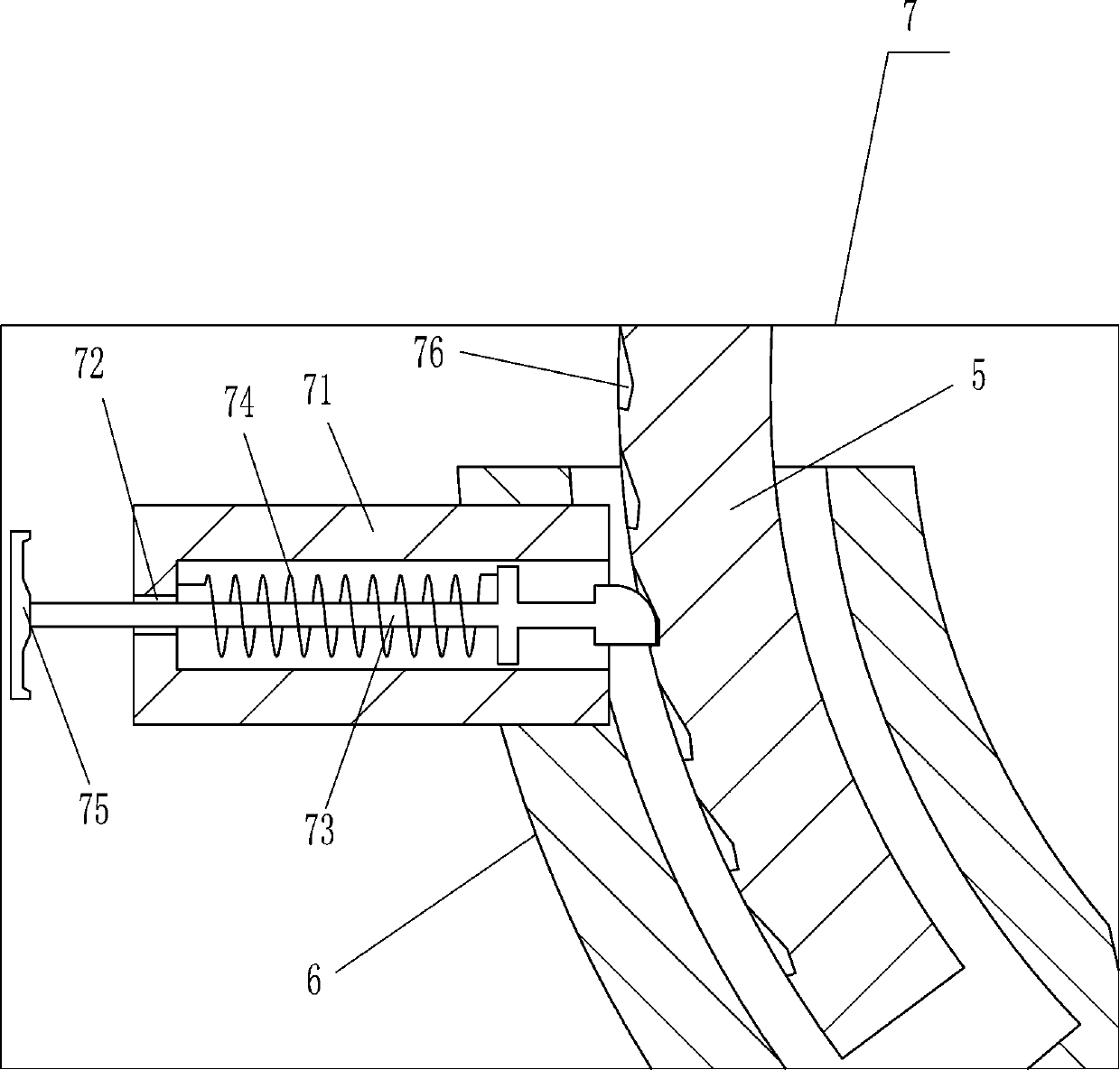

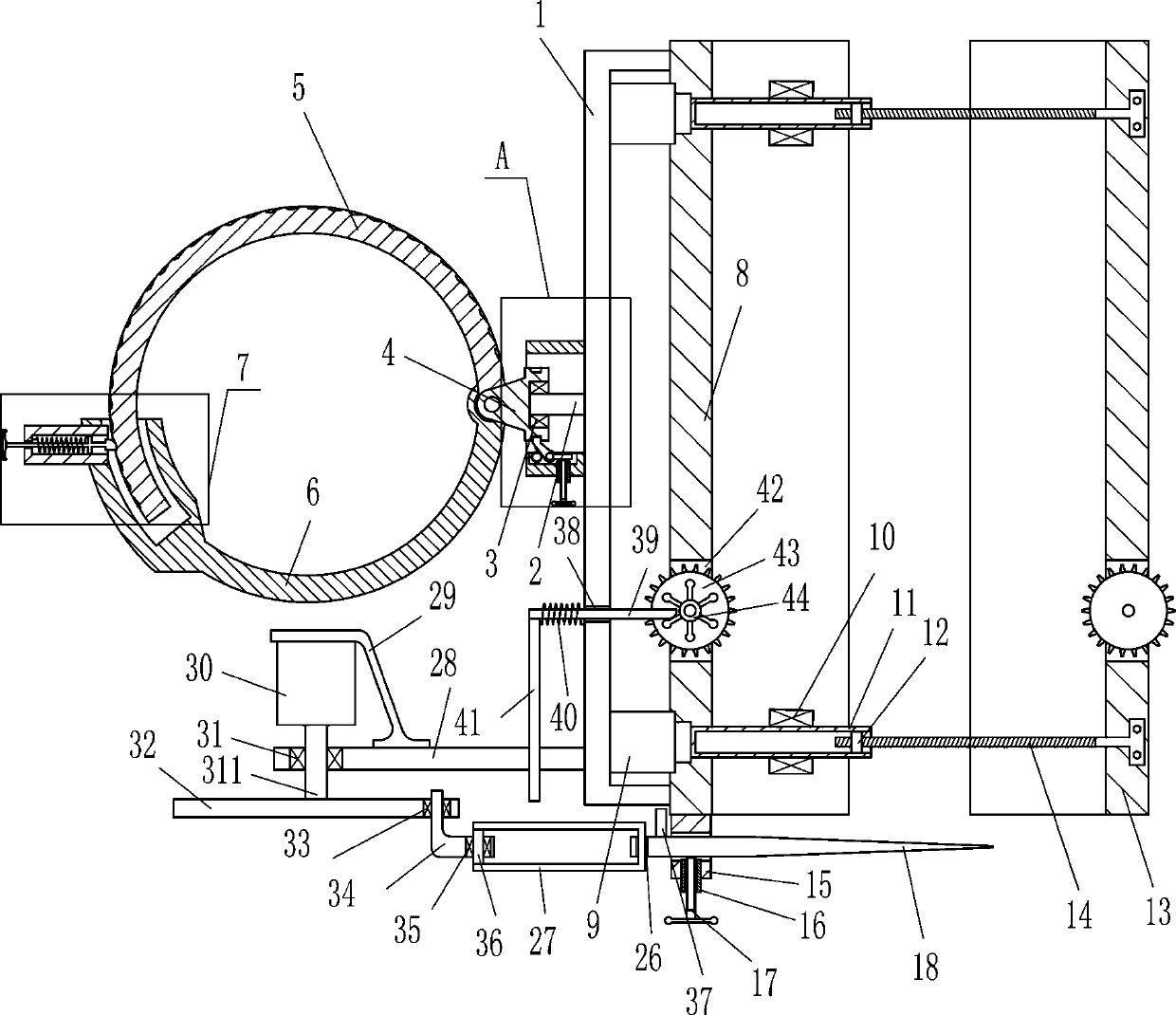

[0016] A banana trunk cutter such as Figure 1-2 As shown, it includes a first support plate 1, a first rotating shaft 2, a first bearing 3, a swing seat 4, a first clamping rod 5, a second clamping rod 6, a fixing device 7, a first clamping plate 8, and a first motor 9 , the second bearing 10, the hollow rotating shaft 11, the nut 12, the second splint 13, the first screw 14, the sliding sleeve 15, the first screw sleeve 16, the second screw 17 and the blade 18, the left middle part of the first support plate 1 There is a first rotating shaft 2, and the first support plate 1 is connected with the first rotating shaft 2 by welding, and the first bearing 3 is installed on the first rotating shaft 2, and the first bearing 3 is located on the left side of the first support plate 1. A bearing 3 is provided with a swing seat 4, and the swing seat 4 is hingedly provided with a first clamping rod 5 and a second clamping rod 6, the first clamping rod 5 is located above the second clam...

Embodiment 2

[0018] A banana trunk cutter such as Figure 1-2 As shown, it includes a first support plate 1, a first rotating shaft 2, a first bearing 3, a swing seat 4, a first clamping rod 5, a second clamping rod 6, a fixing device 7, a first clamping plate 8, and a first motor 9 , the second bearing 10, the hollow rotating shaft 11, the nut 12, the second splint 13, the first screw 14, the sliding sleeve 15, the first screw sleeve 16, the second screw 17 and the blade 18, the left middle part of the first support plate 1 There is a first rotating shaft 2, and a first bearing 3 is installed on the first rotating shaft 2. The first bearing 3 is located on the left side of the first support plate 1. The first bearing 3 is provided with a swing seat 4, and the swing seat 4 is hinged. There are a first clamping bar 5 and a second clamping bar 6, the first clamping bar 5 is located above the second clamping bar 6, the left end of the first clamping bar 5 is positioned in the left end of the ...

Embodiment 3

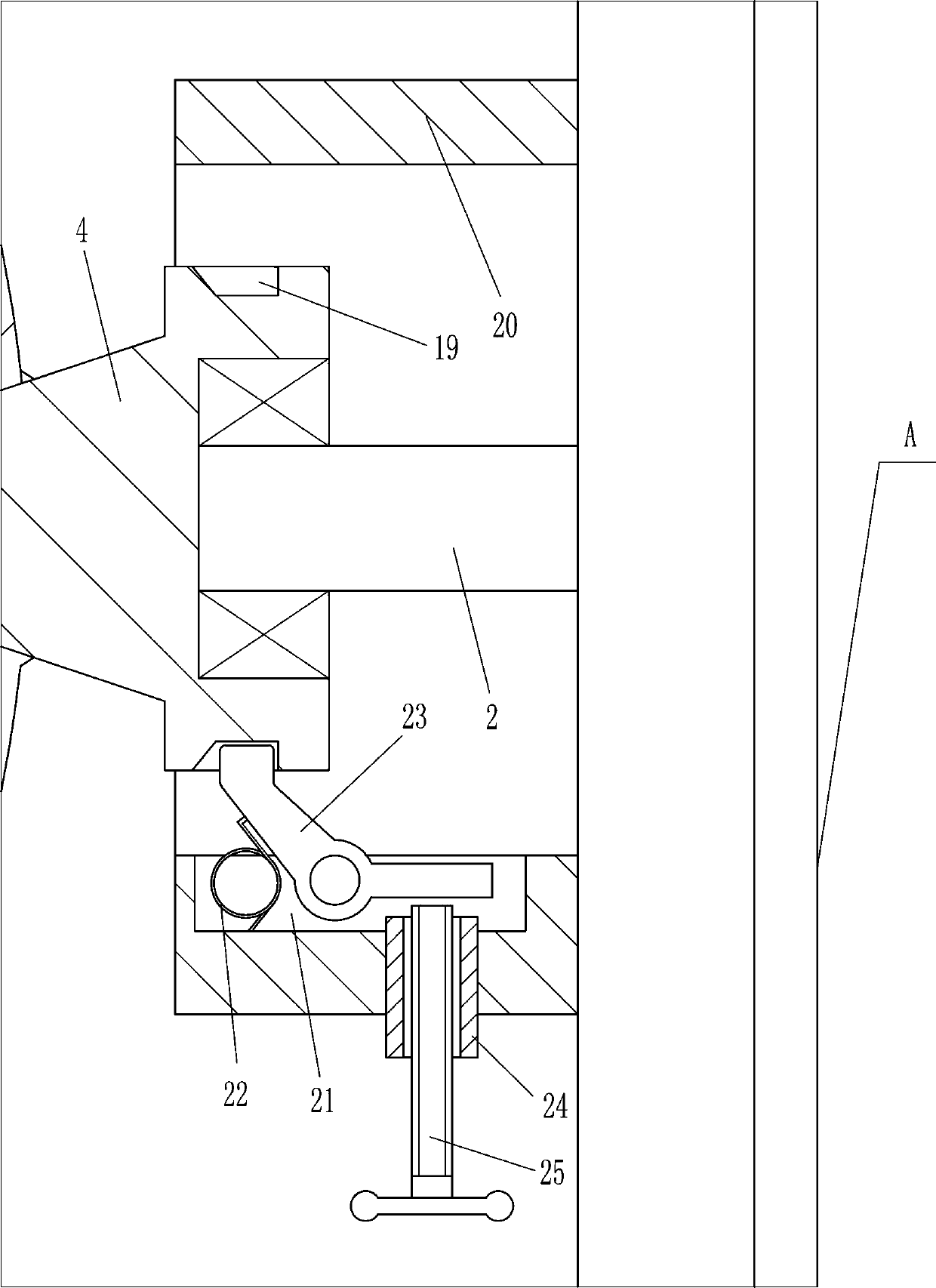

[0021]A banana trunk cutter such as Figure 1-3 As shown, it includes a first support plate 1, a first rotating shaft 2, a first bearing 3, a swing seat 4, a first clamping rod 5, a second clamping rod 6, a fixing device 7, a first clamping plate 8, and a first motor 9 , the second bearing 10, the hollow rotating shaft 11, the nut 12, the second splint 13, the first screw 14, the sliding sleeve 15, the first screw sleeve 16, the second screw 17 and the blade 18, the left middle part of the first support plate 1 There is a first rotating shaft 2, and a first bearing 3 is installed on the first rotating shaft 2. The first bearing 3 is located on the left side of the first support plate 1. The first bearing 3 is provided with a swing seat 4, and the swing seat 4 is hinged. There are a first clamping bar 5 and a second clamping bar 6, the first clamping bar 5 is located above the second clamping bar 6, the left end of the first clamping bar 5 is positioned in the left end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com