Drawer slide rail fast-dismounting structure

A drawer, slide rail technology, applied in the direction of drawers, furniture parts, home appliances, etc., can solve the problems of affecting appearance and use, drawer interference or unevenness, complex structure, etc., to achieve simple structure, avoid interference or unevenness, assembly, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

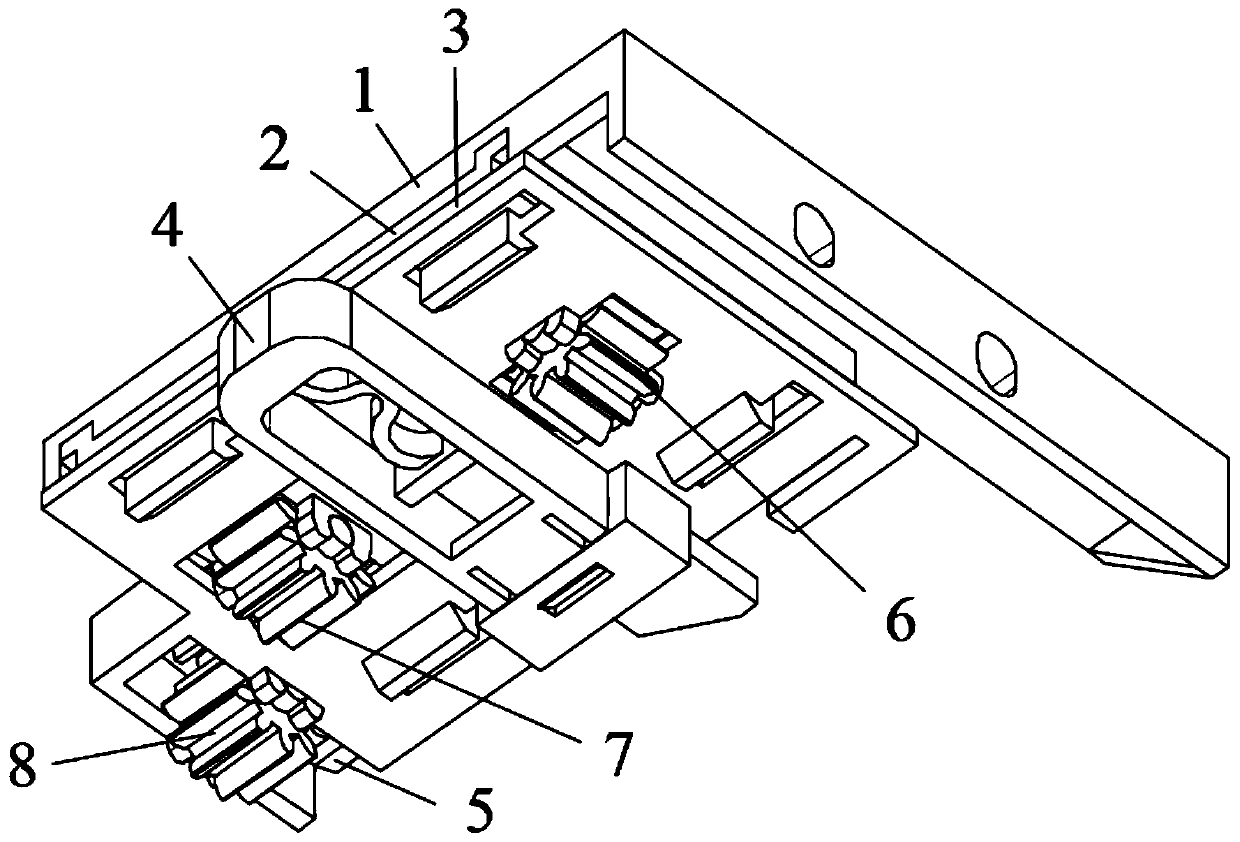

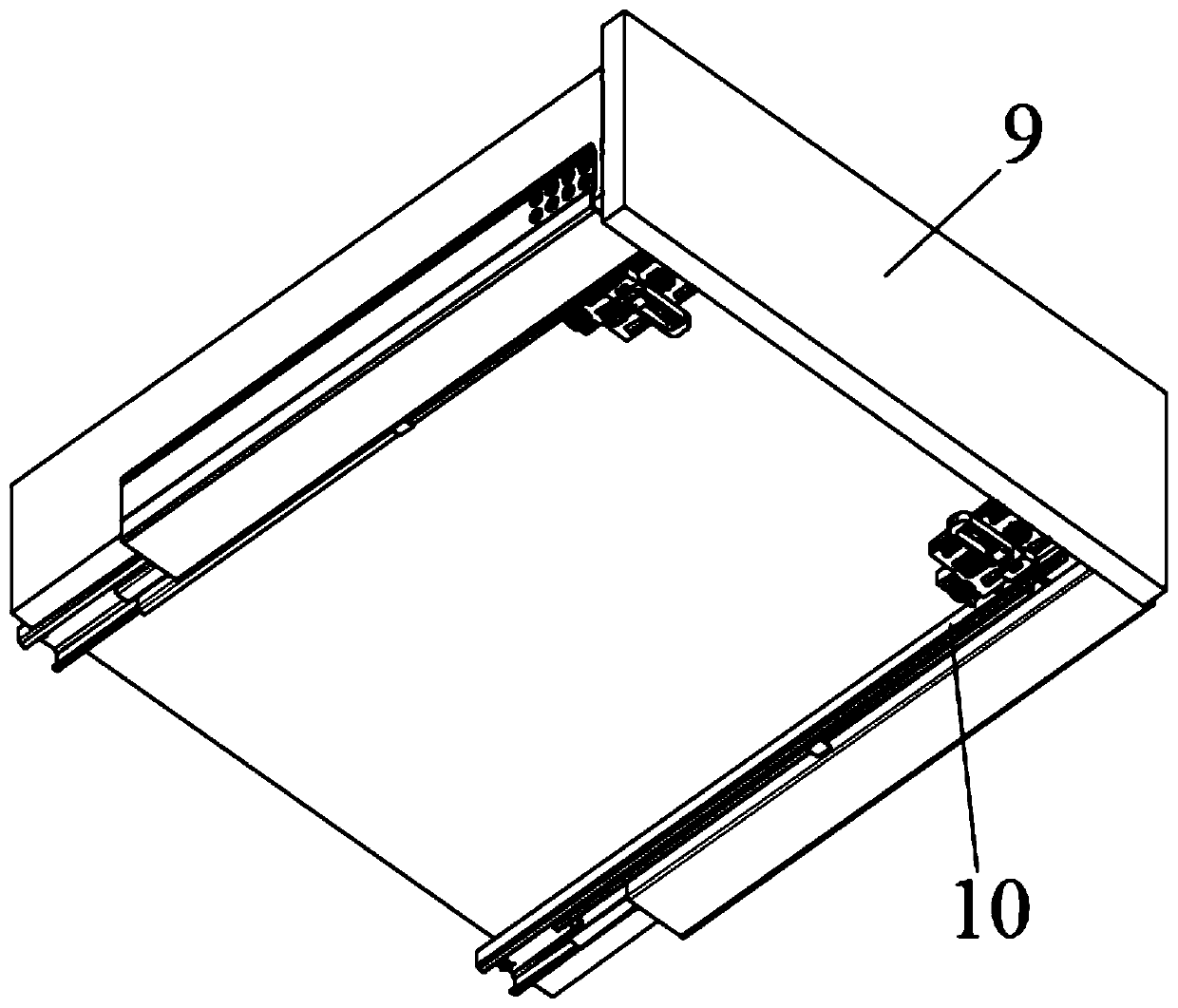

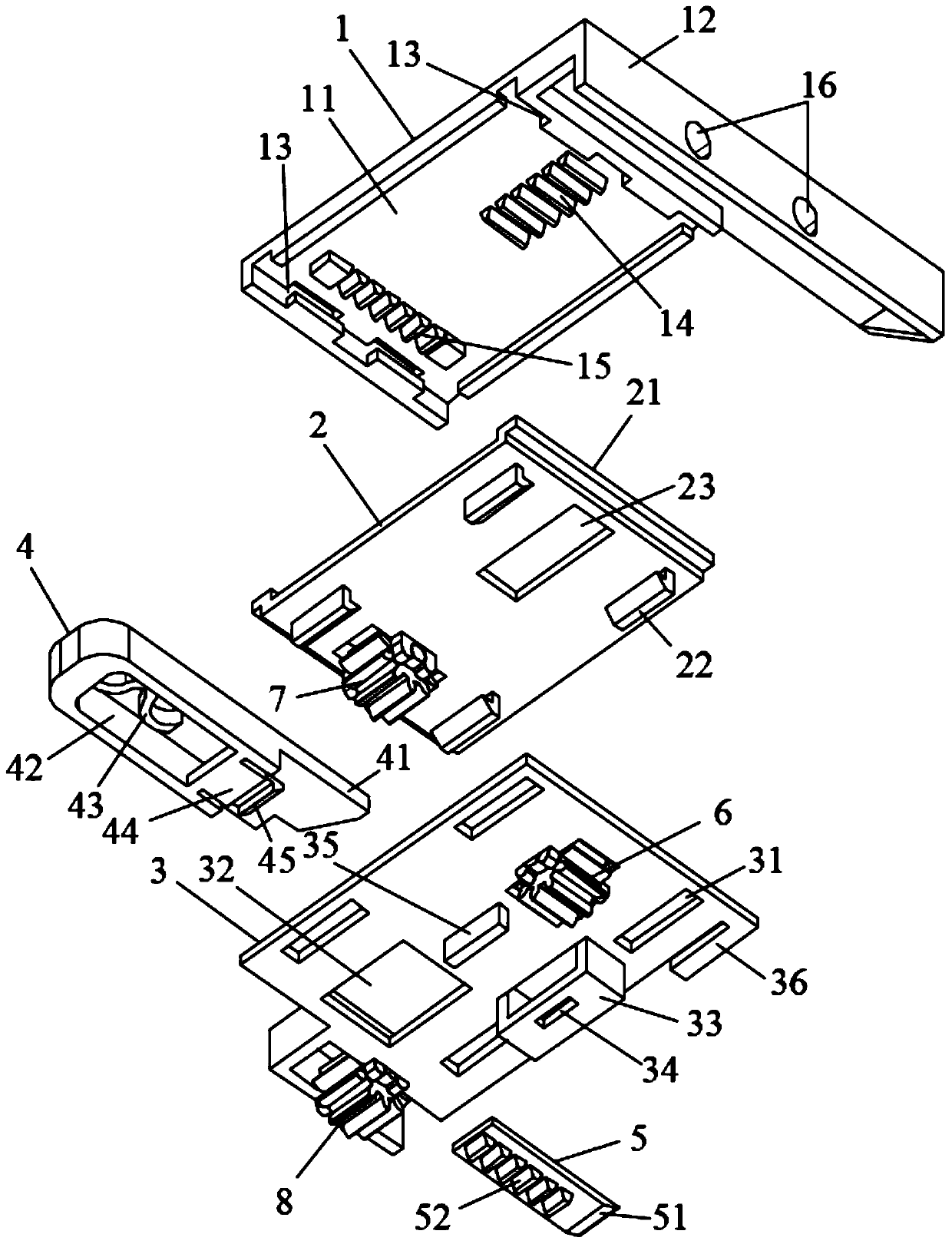

[0025] Such as Figure 1 to Figure 10 As shown, the present embodiment provides a quick-release structure for drawer slide rails, which includes a fixed mounting plate 1, a left and right moving plate 2, a front and rear moving plate 3, a slider 4, and a height adjustment plate 5; The front end is fixedly connected with the drawer 9; the left and right moving plates 2 are slid left and right relative to the fixed installation plate 1, the front and rear moving plates 3 are slid forward and backward relative to the left and right moving plates 2, and the height adjustment plate 5 is slid relative to the front and rear moving plates 4. Sliding assembly left and right; the height adjustment plate 5 includes a height adjustment slope 51 at the front end, and the height adjustment slope 51 is inserted between the inner rail and the drawer by moving the height adjustment board 5 left and right to realize the height adjustment of the drawer 9 relative to the inner rail 10; The front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com