Composite nano material and preparation method and application thereof

A technology of composite nanomaterials and supramolecular compounds, which is applied in the field of nanomaterials to achieve good biocompatibility, low cytotoxicity and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

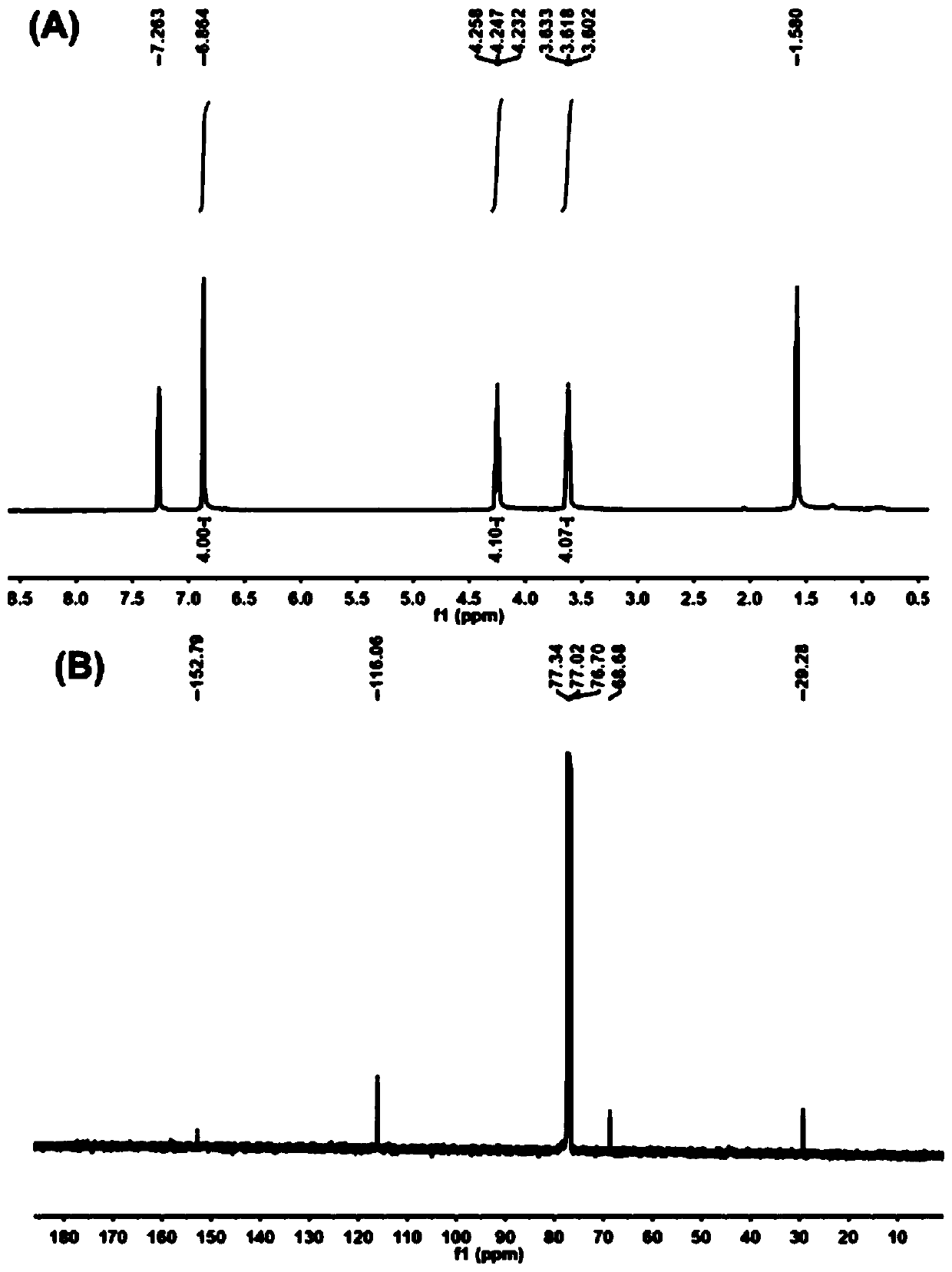

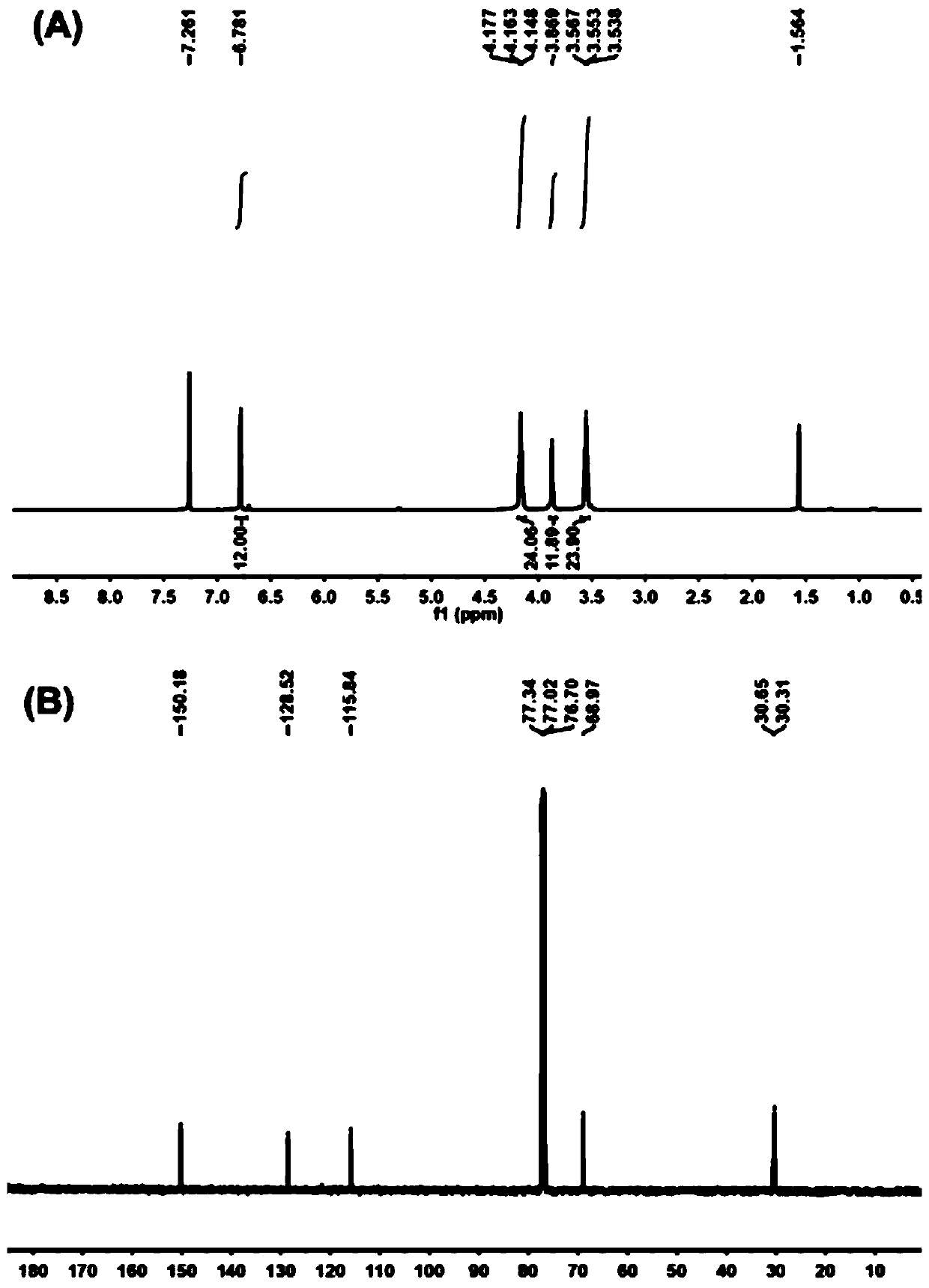

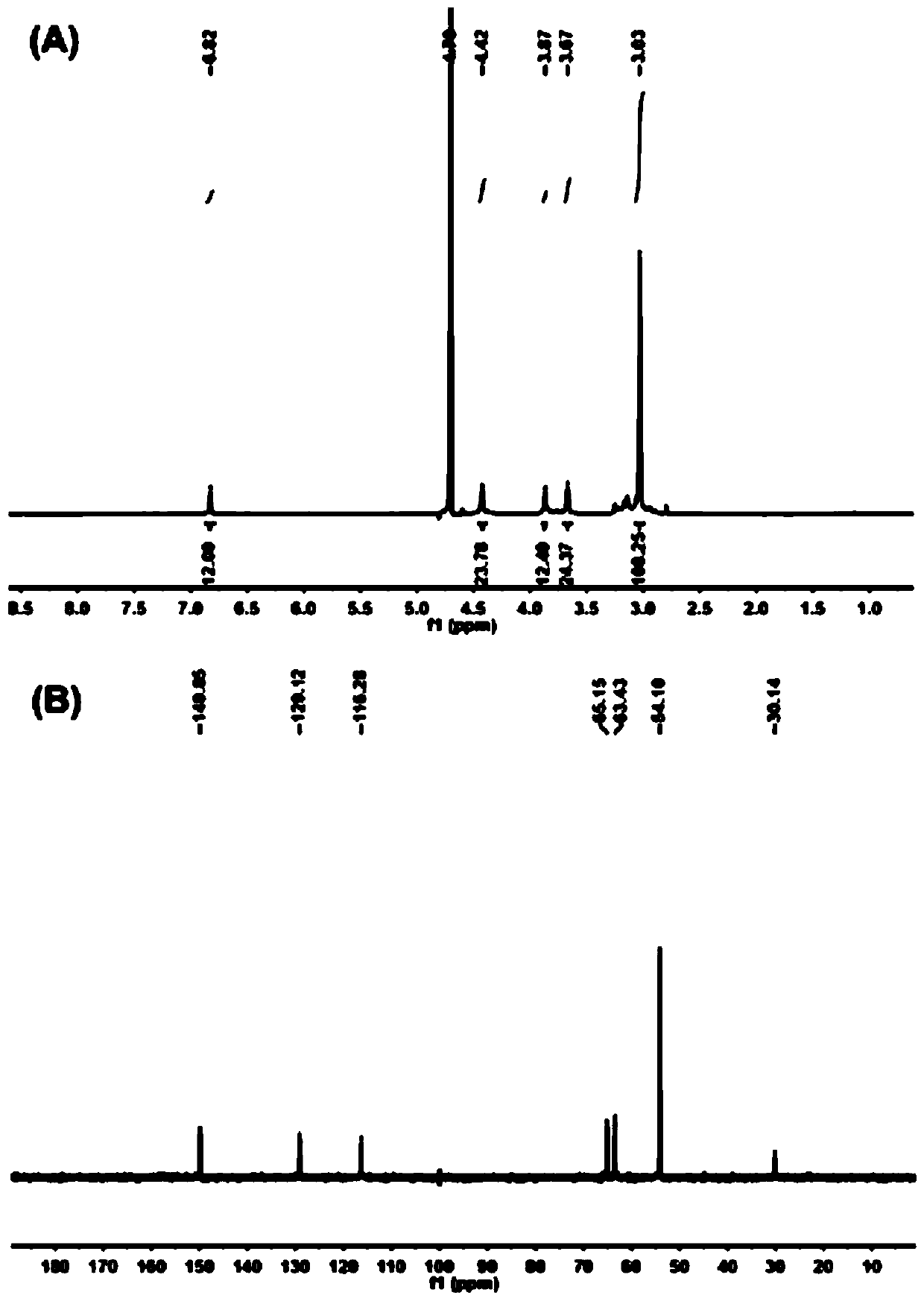

Image

Examples

Embodiment 1

[0034] The preparation method of BPNS@cPA6 composite nanomaterials, the specific steps are as follows:

[0035] (1) Black phosphorus crystals (100 mg) were dispersed in anaerobic water (50 mL), sonicated in an ice bath for 10 h, and centrifuged at 1500 rpm for 10 minutes to obtain a suspension of BPNS to remove unstripped black phosphorus crystals, and then Centrifuge at 7000rpm for 15 minutes to obtain the BPNS precipitate, so as to shorten the time required for subsequent freeze-drying, and finally freeze-dry to obtain powder. The whole process is carried out in a dark environment;

[0036] (2) Synthesize cPA6 according to the report in the literature "A cationic water-soluble pillar[5]arene: synthesis and host–guest complexation with sodium 1-octanesulfonate", the specific steps are as follows:

[0037] Step 1, carbon tetrabromide (39.8g, 120mmol) was slowly added into 250mL of anhydrous hydroquinone bis(2-hydroxyethyl) ether (10.0g, 50.4mmol) and triphenylphosphine (31.5g,...

Embodiment 2

[0049] The preparation method of BPNS@cPA6 composite nanomaterials, the specific steps are as follows:

[0050] (1) Black phosphorus crystals (100 mg) were dispersed in anaerobic water (50 mL), sonicated in an ice bath for 6 h, and then centrifuged at 2000 rpm for 10 minutes to obtain a suspension of BPNS to remove unstripped black phosphorus crystals, Then centrifuge at 10,000rpm for 15 minutes to obtain the BPNS precipitate to shorten the time required for subsequent freeze-drying, and finally freeze-dry to obtain powder. The whole process is carried out in a dark environment;

[0051] (2) Prepare cPA6 according to the method of Example 1, disperse the dry powder (10 mg) prepared in step (1) and cPA6 (20 mg) in anaerobic water (10 mL), and ultrasonically in an ice bath for 10 min, After stirring for 6 hours, centrifuge and wash twice at 7000rpm to remove excess cPA6. The whole process was carried out in a dark environment, and BPNS@cPA6 composite nanomaterials were obtained....

Embodiment 3

[0053] A method for preparing BPNS@cPA6 nanometer material, the specific steps are as follows:

[0054] (1) Black phosphorus crystals (100mg) were dispersed in anaerobic water (50mL), sonicated in an ice bath for 12h, and then centrifuged at 500rpm for 10 minutes to obtain a suspension of BPNS to remove unstripped black phosphorus crystals, Then centrifuge at 12000rpm for 15 minutes to obtain the BPNS precipitate to shorten the time required for subsequent freeze-drying, and finally freeze-dry to obtain powder. The whole process is carried out in a dark environment;

[0055] (2) Prepare cPA6 according to the method of Example 1, disperse the dry powder (20 mg) prepared in step (1) and cPA6 (10 mg) in anaerobic water (10 mL), and ultrasonically in an ice bath for 30 min, After stirring for 3 hours, centrifuge washing at 12000rpm for 4 times to remove excess cPA6. The whole process was carried out in a light-proof environment, and BPNS@cPA6 composite nanomaterials were obtained....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com