Human-machine cooperation full-automatic ultrasonic welding equipment

A technology of ultrasonic welding and human-machine collaboration, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing enterprise costs and risks, employee health threats, etc., and achieve complete functions, low production costs, and prevention of release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

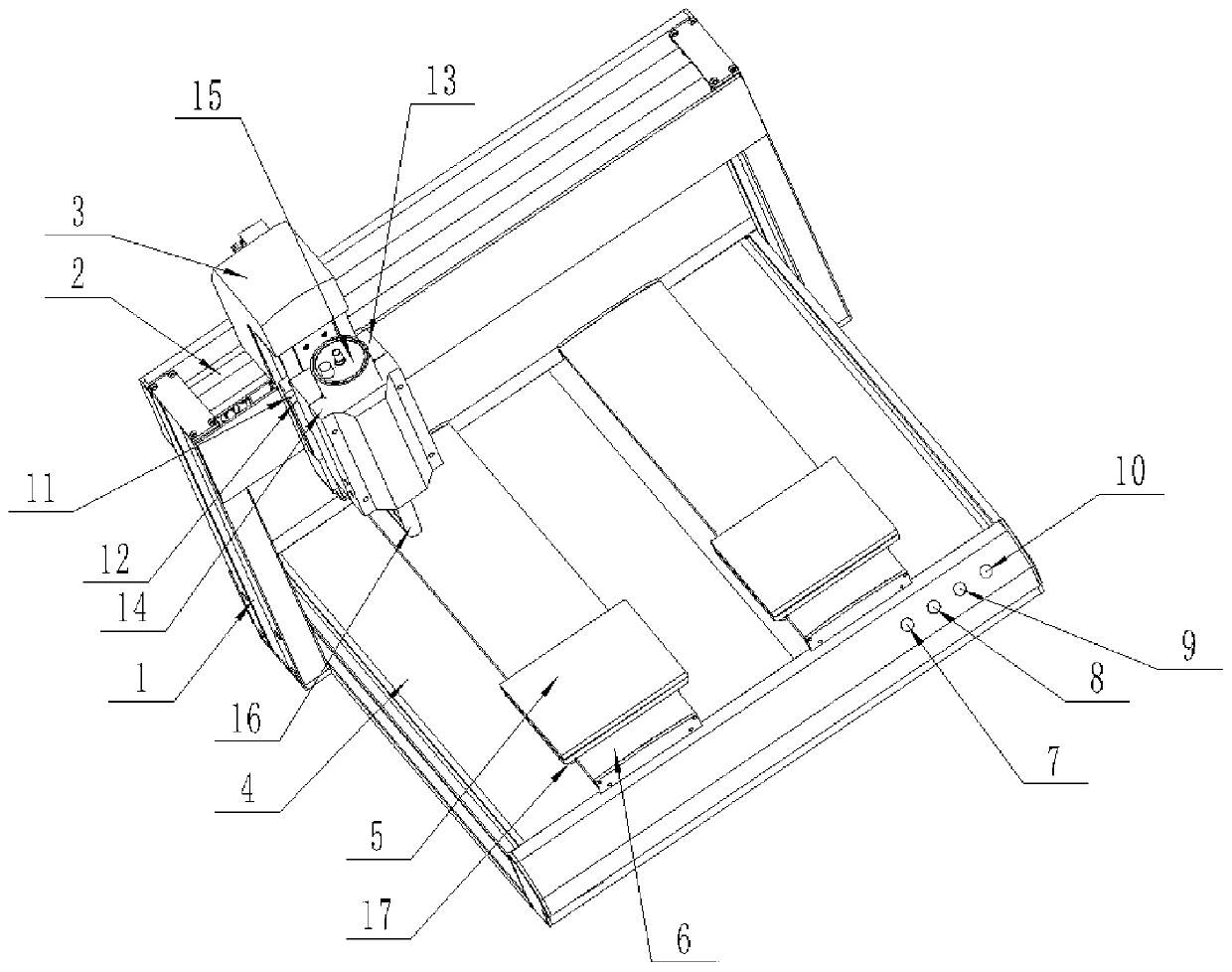

[0012] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a human-machine collaborative automatic ultrasonic welding equipment, including a support base 1, an X-axis assembly 2, a Z-axis assembly 3, a base 4, a product positioning fixture 5, and a Y-axis assembly 6. Fixed plate 11, cover plate 12, fixture bottom plate 13, fixture cover plate 14, ultrasonic welder 15, welding head 16 and slide seat 17; the base 4 is arranged under the support base 1; the upper end of the support base 1 An X-axis assembly 2 is provided; the fixed end of the Z-axis assembly 3 is slidably connected to the X-axis assembly 2, and a fixed plate 11 is fixedly connected to the movable end of the Z-axis assembly 3; the fixed plate 11 is fixed A cover plate 12 is connected, and a clamp base plate 13 is fixedly connected on the cover plate 12; the ultrasonic welder 15 is fixedly connected to the clamp base plate 13 through the clamp cover plate 14; the bottom end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com