Detection tool based on rebound performance test of high-strength plate beam structure

A technology for resilience performance and testing tooling, which is used in measuring devices, strength characteristics, and testing material strength by applying a stable bending force. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

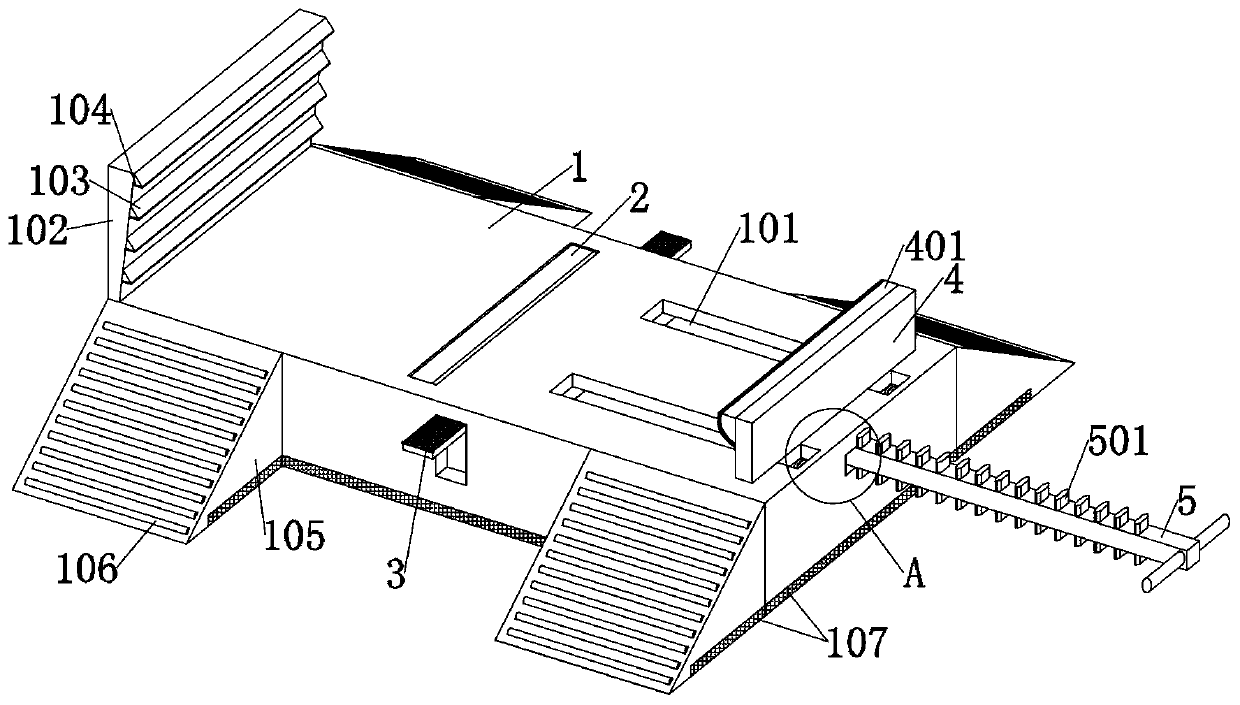

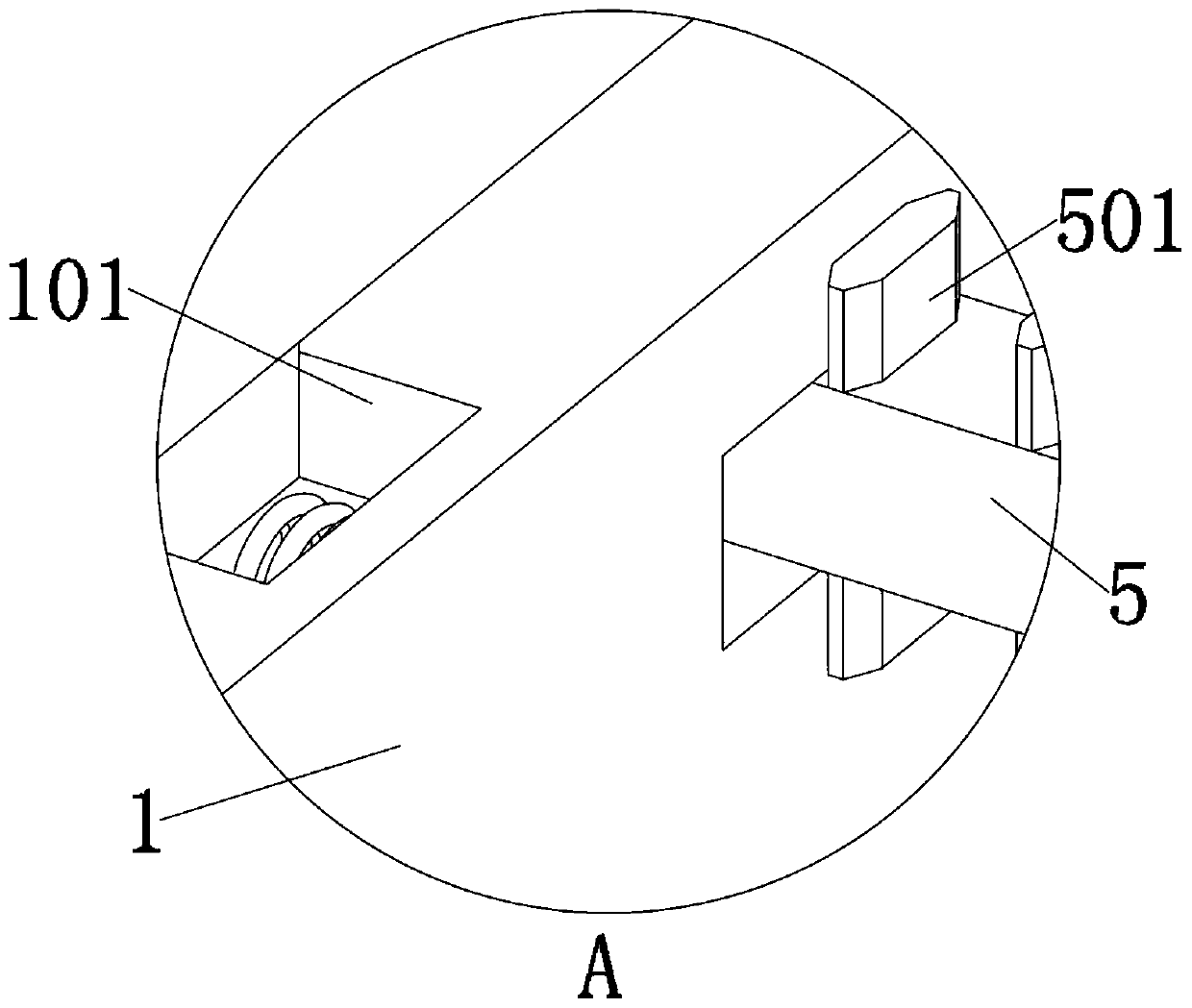

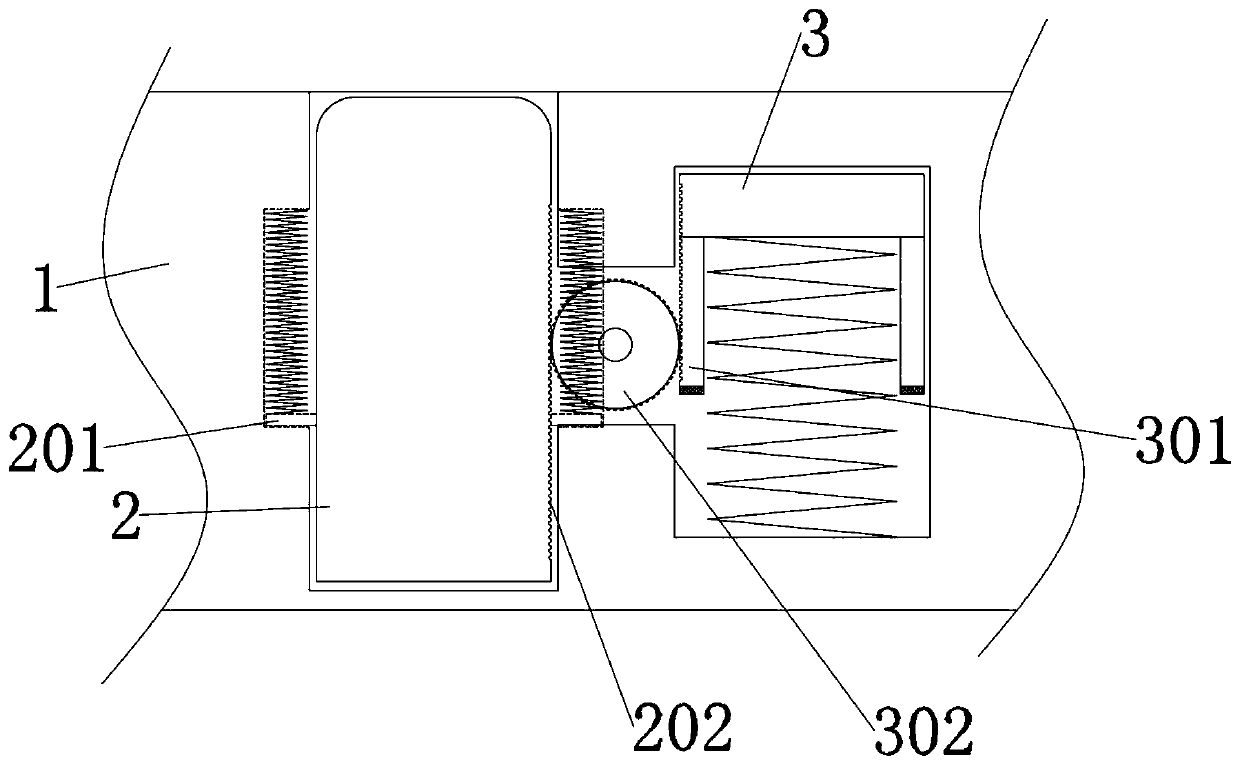

[0028] as attached figure 1 to attach Figure 5 Shown:

[0029] The present invention provides a detection tool based on the resilience performance test of a high-strength plate beam structure, which includes a main body 1, a guide groove 101, a top plate 102, a fixing part 103, an anti-skid part 104, a side part 105, a slide bar 106, a bottom part 107, Moving block 2, force plate 201, force tooth 202, pedal 3, guide 301, cross gear 302, moving part 4, front block 401, inner part 402, connecting hole 403, pull rod 5 and baffle plate 501; The main body 1 is a rectangular plate-shaped structure, and guide grooves 101 are provided on both sides of the upper right end of the main body 1, and a spring is installed inside the guide groove 101; the bottom of the fixing member 103 is fixedly connected with the main body 1 The upper left end of the side piece 105 is connected to the upper left end, and the anti-skid piece 104 is a rectangular plate-shaped structure, and the anti-skid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com