Efficient buffer energy absorption device for automobiles

An energy-absorbing device and high-efficiency technology, applied in the field of auto parts, can solve the problems of heavy energy-absorbing boxes, crushing characteristics, low energy-absorbing capacity and collision stability, etc., achieve high buffer energy-absorbing performance, and reduce vehicle collision damage And the effect of personal injury, good buffer energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

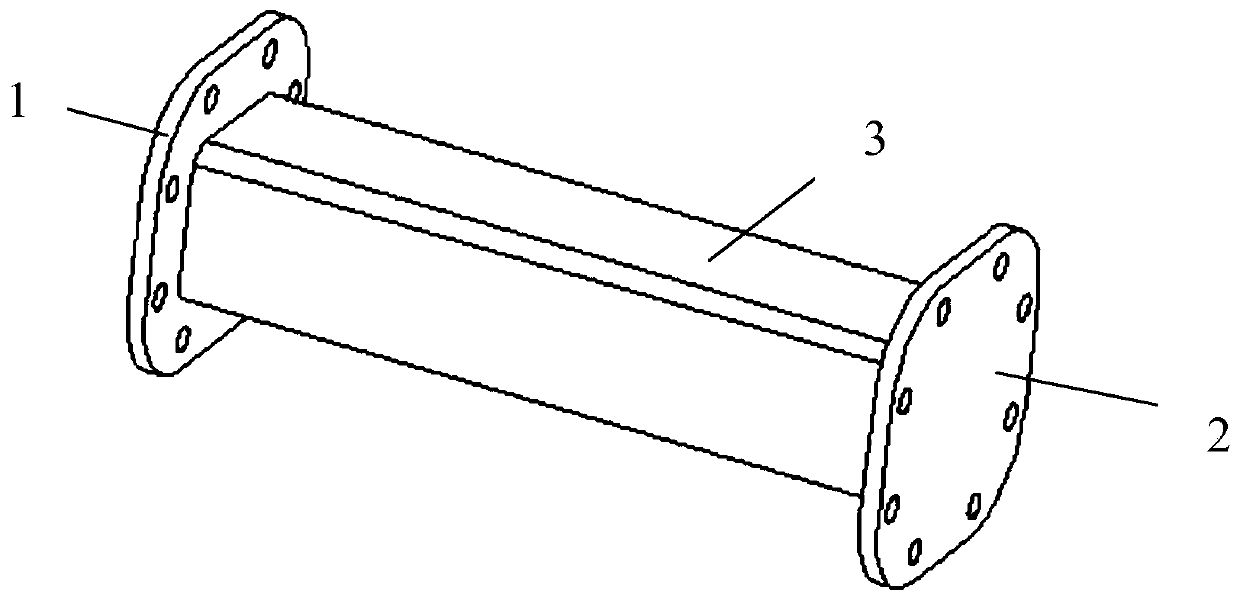

[0035] Such as Figure 1a , an automobile high-efficiency buffer energy-absorbing device provided in this embodiment includes a first connecting plate 1, a second connecting plate 2 and a housing 3, and the first connecting plate 1 and the second connecting plate 2 are respectively arranged at both ends of the housing , which are used to connect the anti-collision beam and longitudinal beam of the car respectively.

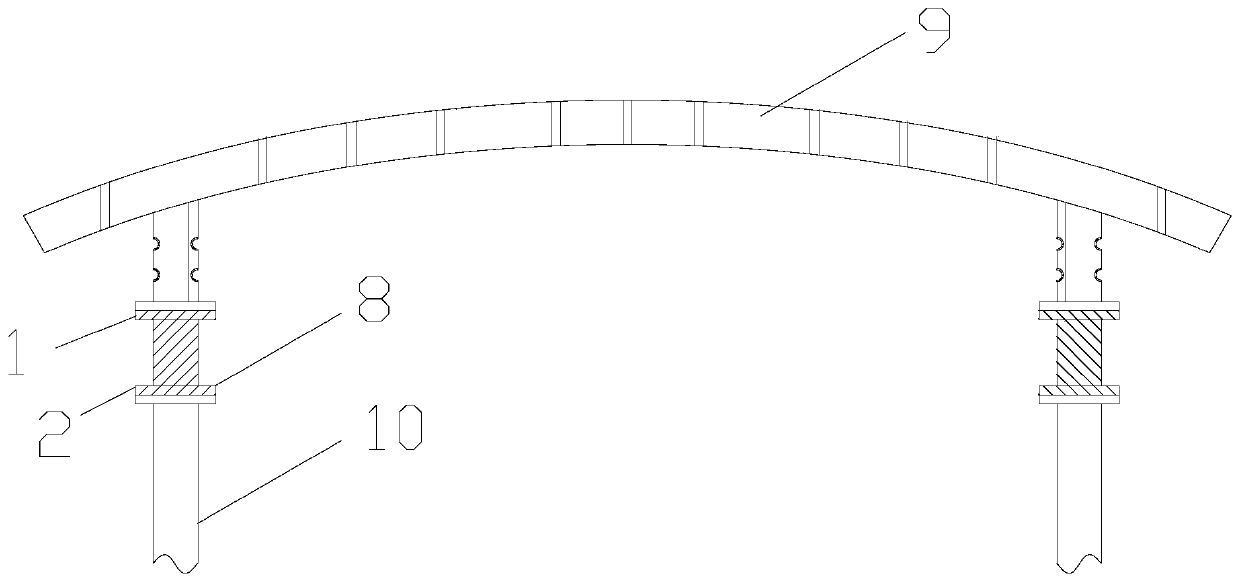

[0036] Such as Figure 1b , comprising a buffer energy-absorbing device 8, an anti-collision beam 9 and a longitudinal beam 10, the first connecting plate 1 of the buffering energy-absorbing device 8 is fixedly connected to the anti-collision beam 9, the second connecting plate 2 is fixedly connected to the longitudinal beam 10, the two sides A buffer energy-absorbing device 8 is connected to the longitudinal beams 9 .

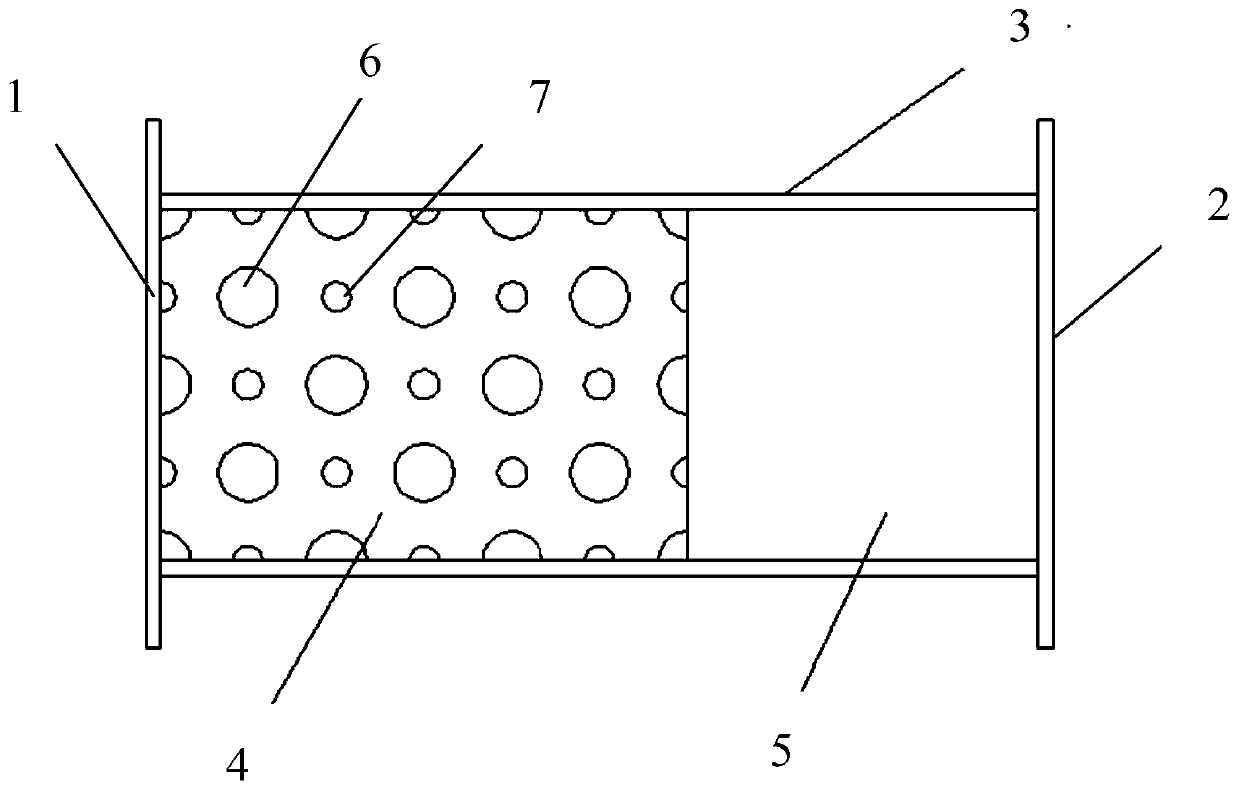

[0037] Such as figure 2 The shell 3 is provided with a porous aluminum alloy section 4 and a hard rubber section 5, the porous aluminum alloy ...

Embodiment 2

[0049] Such as Figure 5 , The difference between this embodiment and Embodiment 1 is that the housing 3 has a corrugated structure.

Embodiment 3

[0051] Such as Figure 6 , The difference between this embodiment and Embodiment 1 is that the casing 3 is a broken line structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com