an engineering ship

A technology for engineering ships and reamers, applied in the field of ships, can solve problems such as disadvantages, simple functions, and inconvenience in moving ships.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

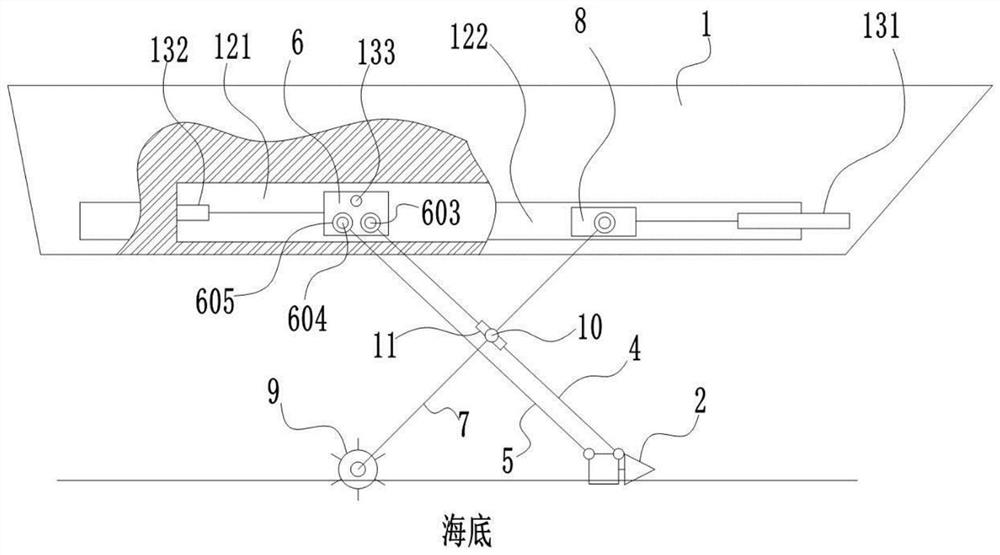

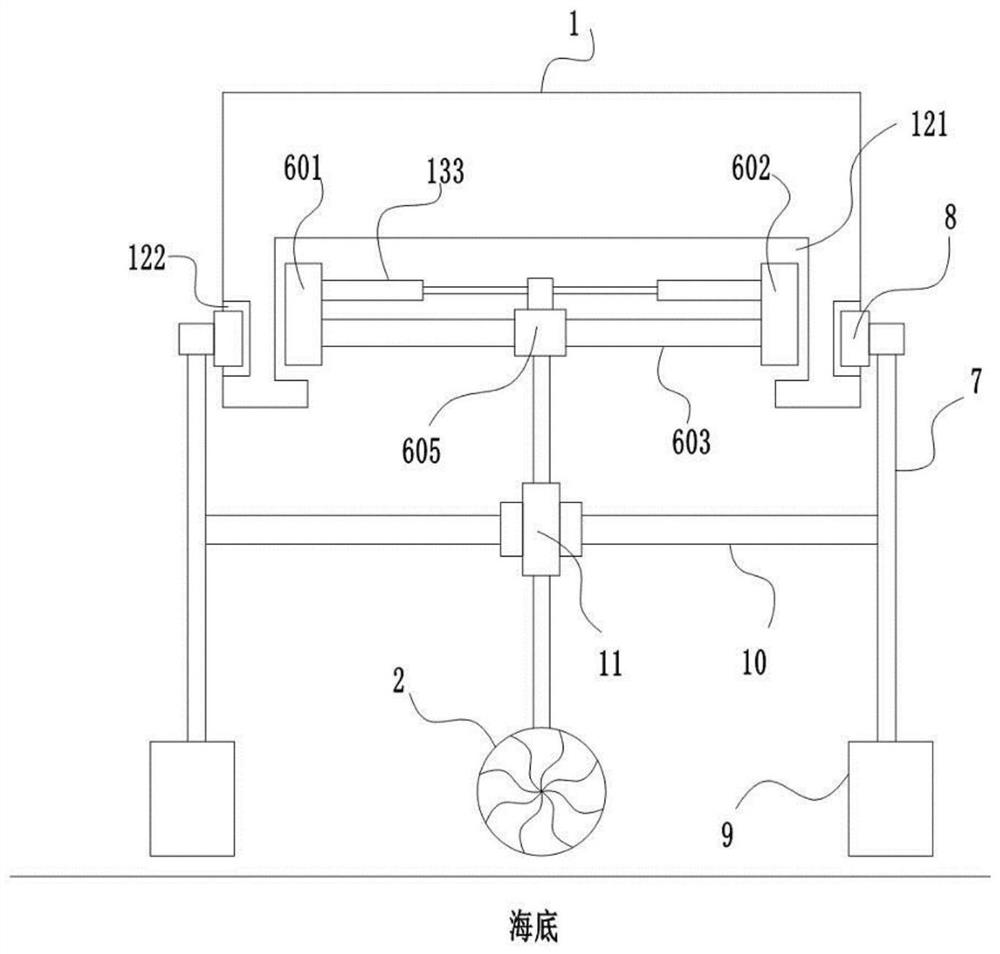

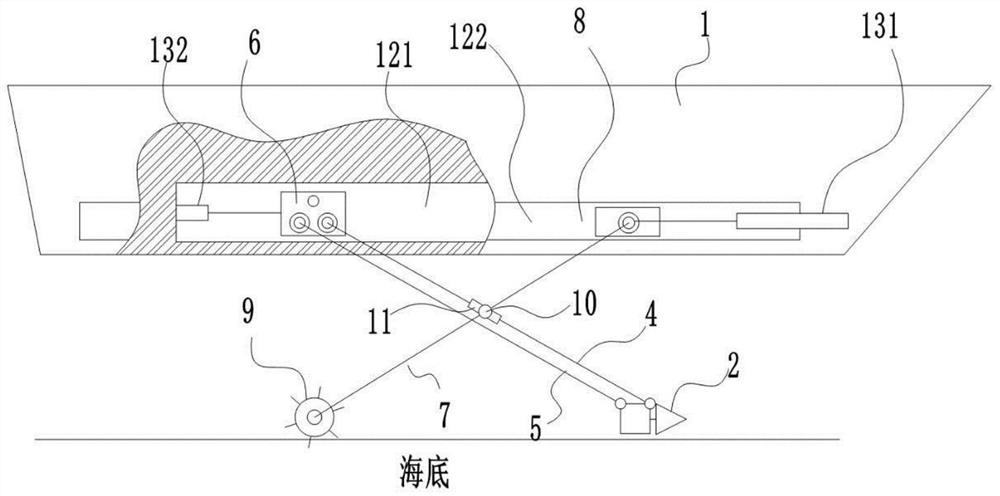

[0026] Such as figure 1 , 2 As shown, an engineering ship includes a hull 1, a reamer 2, and a reamer control device, and a dredger suction pipe or a cutter suction pump can be arranged behind the reamer.

[0027] The reamer control device comprises a reamer bracket, and the reamer bracket includes a first rack bar 4 and a second rack bar 5 which are parallel to each other, and the upper ends of the first rack bar 4 and the second rack bar 5 are connected on the On the reamer slide block 6, the lower ends of the first frame bar 4 and the second frame bar 5 are rotatably connected to the reamer 2, so that the reamer slide block 6, the first frame bar 4, the second frame bar 5, and the reamer 2 The four actually constitute a parallel four-bar kinematic mechanism. So that when the first rack bar 4 and the second rack bar 5 rotate relative to the reamer slider 6, the orientation of the reamer slider 6 remains unchanged.

[0028] It also includes a support rod 7 intersecting wit...

Embodiment 2

[0039] Such as Figure 8 As shown, the second support rod 5 is a telescopic rod with a controllable length, for example, the expansion and contraction can be controlled by the hydraulic cylinder 134 , so that the direction of the reamer 2 can be adjusted by controlling the expansion and contraction of the second support rod 5 . Of course, it may also be that: the first support rod, the second support rod and the support rod are all telescopic rods with controllable lengths, so as to improve the flexibility of control and make the reamer control device more flexible in deformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com