Lamplight tracking system and excavator

A technology for tracking systems and excavators, applied to earth movers/excavators, construction, etc., to achieve the effects of improving excavation efficiency, improving vision, and improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

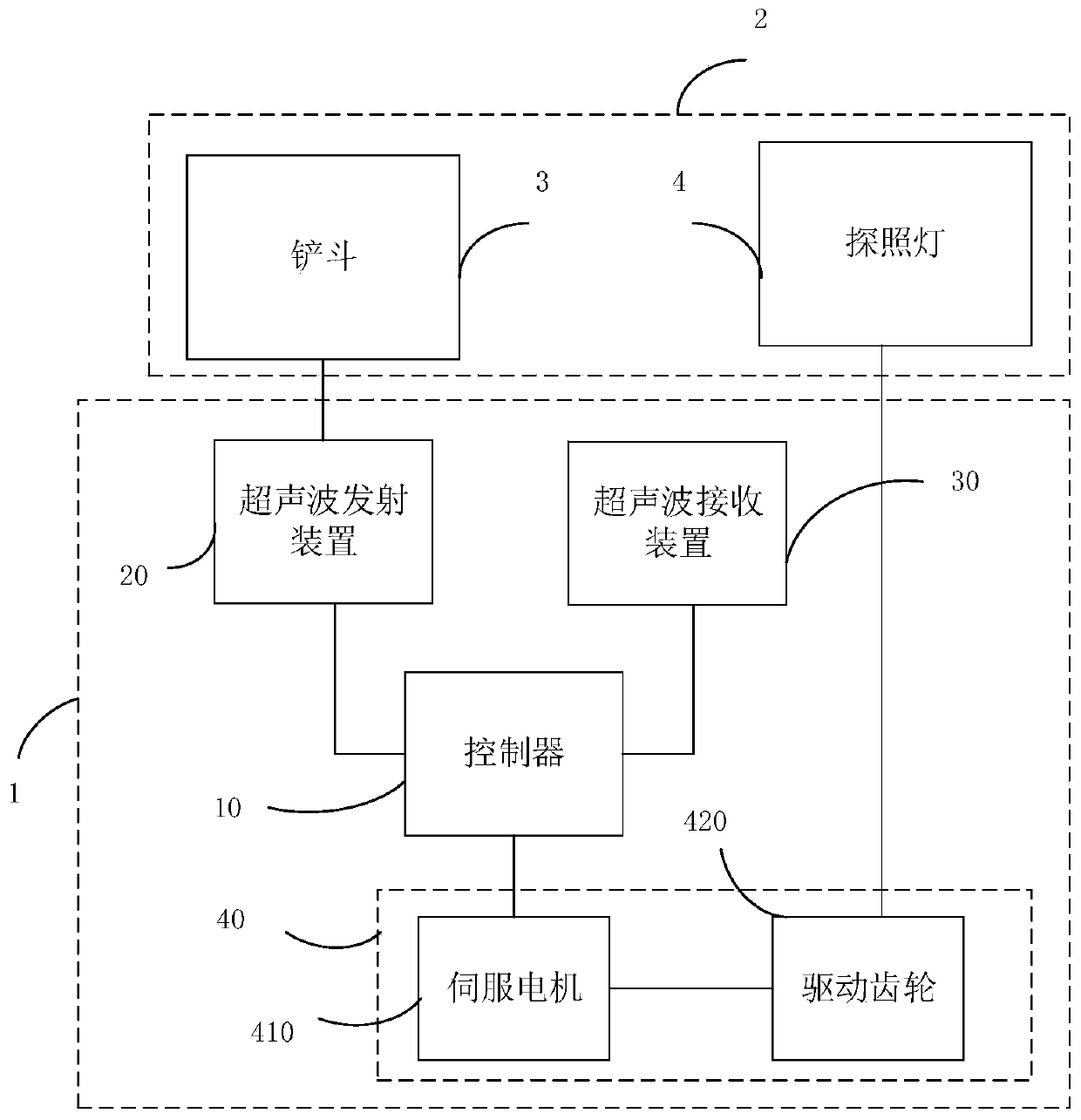

[0049] Please refer to figure 1, this embodiment proposes a light tracking system 1, which can be applied to the excavator 2. By positioning the bucket 3 of the excavator 2, the searchlight 4 is controlled to automatically track the bucket 3, which can improve the safety of night work sex etc. The light tracking system 1 will be described in detail below.

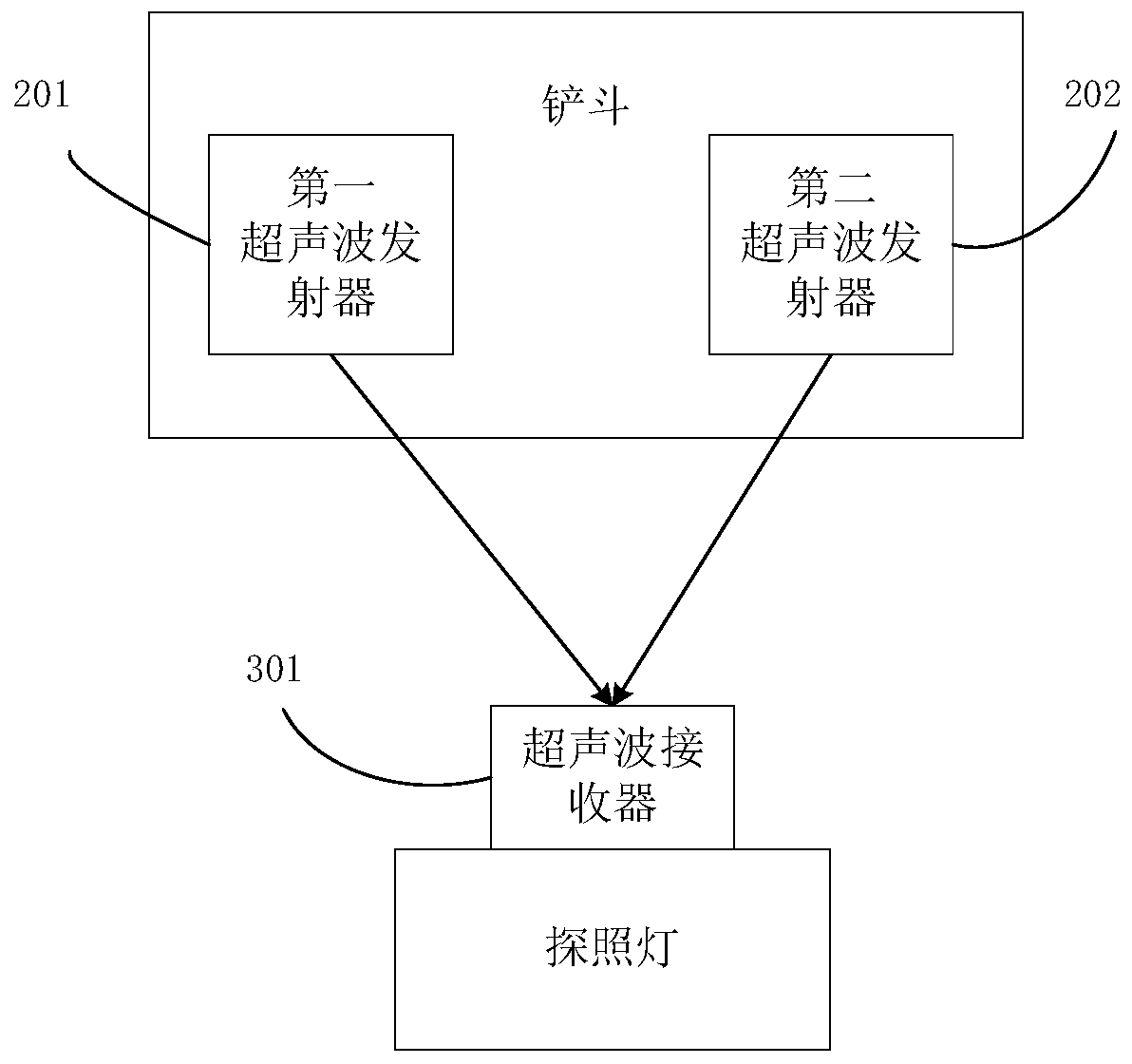

[0050] Such as figure 1 As shown, the light tracking system 1 includes: a controller 10 and an ultrasonic transmitting device 20 connected to the controller 10, an ultrasonic receiving device 30, and a driving device 40, wherein the driving device 40 is connected to the searchlight 4 of the excavator 2 , the ultrasonic emitting device 20 is arranged on the bucket 3 of the excavator 2 .

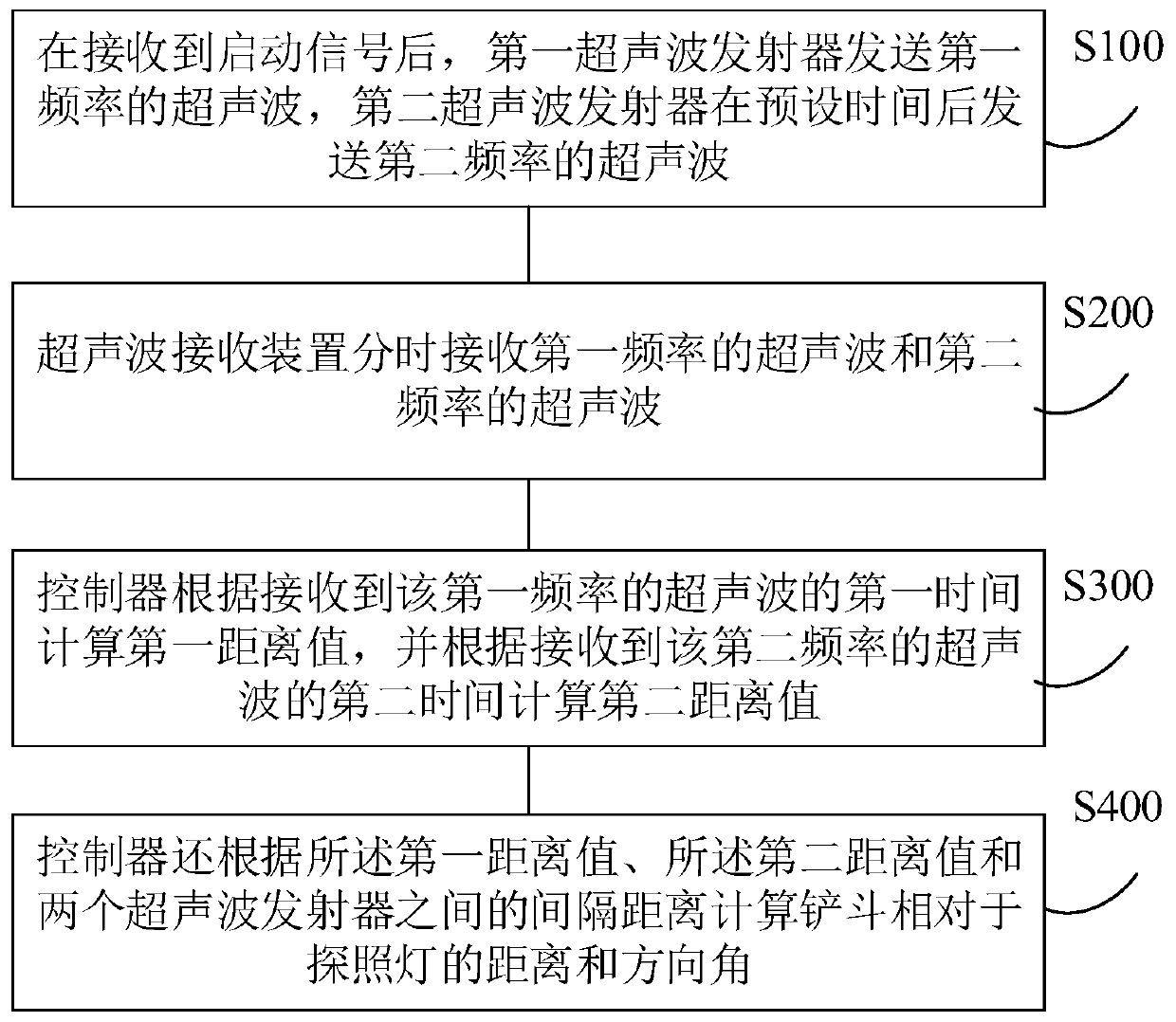

[0051] The controller 10 can be used to send an activation signal to notify the ultrasonic emitting device 20 to transmit ultrasonic signals when the light tracking system 1 needs to be activated.

[0052] Optionally, the light tracking...

Embodiment 2

[0080] Please refer to figure 1 , based on the above-mentioned embodiment 1, this embodiment proposes an excavator 2, the excavator 2 includes a bucket 3, a searchlight 4 and a light tracking system 1, wherein the light tracking system 1 can use the light in the above-mentioned embodiment 1 tracking system.

[0081] Exemplarily, the light tracking system 1 includes a controller 10 and an ultrasonic transmitting device 20, an ultrasonic receiving device 30, and a driving device 40 respectively connected to the controller 10, and the driving device 40 is connected to the searchlight 4, so The ultrasonic emitting device 20 is arranged on the bucket 3;

[0082] The controller 10 is configured to send an activation signal to the ultrasonic emitting device 20;

[0083] The ultrasonic emitting device 20 is used for emitting an ultrasonic signal after receiving the activation signal;

[0084] The controller 10 is also used to calculate the position information of the bucket accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com