A side suction range hood

A range hood, side suction technology, applied in the direction of oil fume removal, heating methods, household stoves/stoves, etc., can solve the problems of cumbersome process, design compensation cannot be determined at one time, and reduce the life of the driving mechanism of the smoke baffle. Achieve the effect of improving strength, eliminating movement hysteresis, solving degumming problems and deformation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

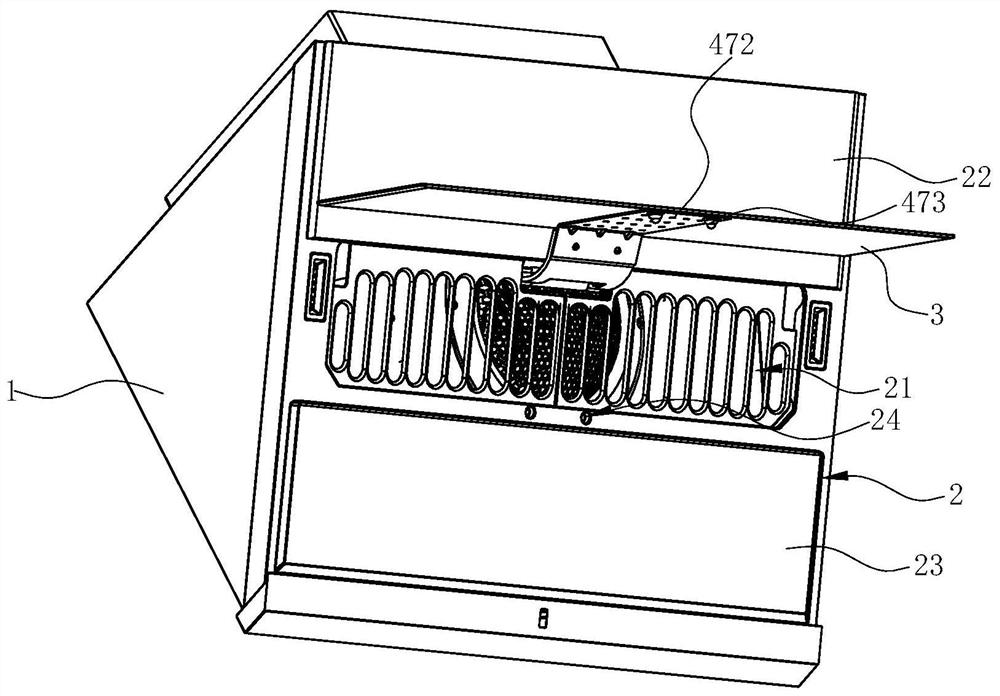

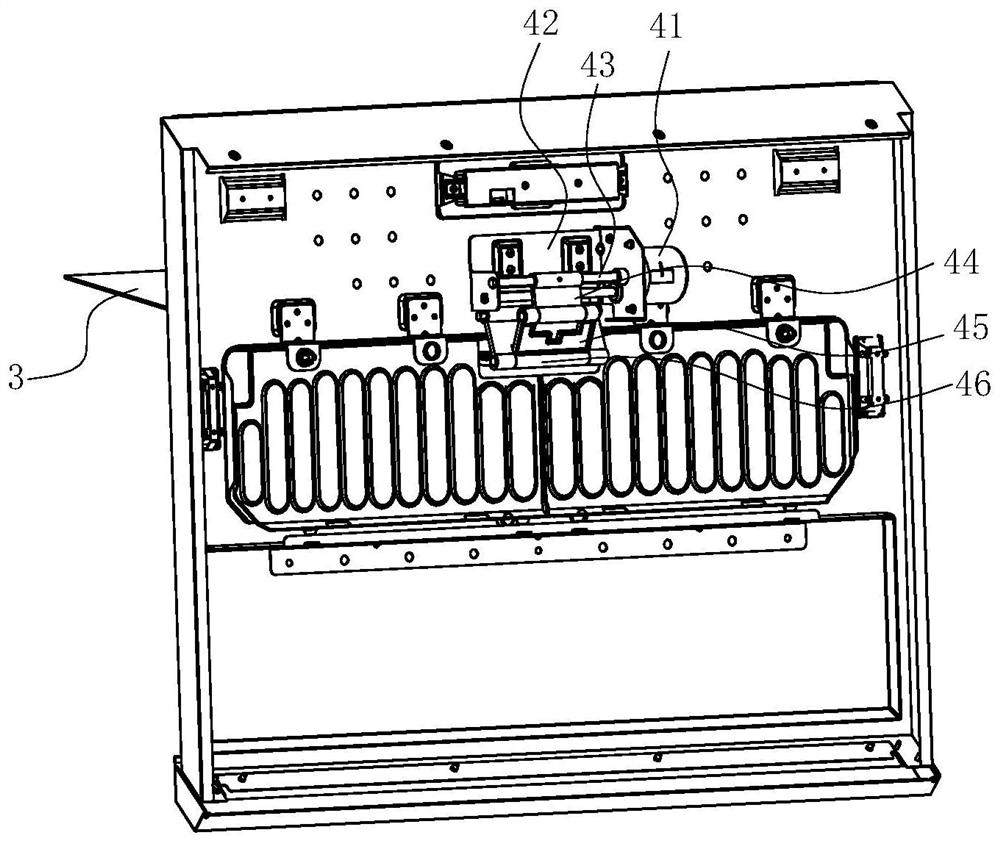

[0025] see Figure 1 ~ Figure 4 , a side suction range hood comprising a housing 1 , a panel 2 arranged on the front side of the housing 1 , and a smoke baffle 3 . For ease of description, in this specification, "front", "rear", "left", "right", "up", and "down" refer to the direction of the range hood relative to the user.

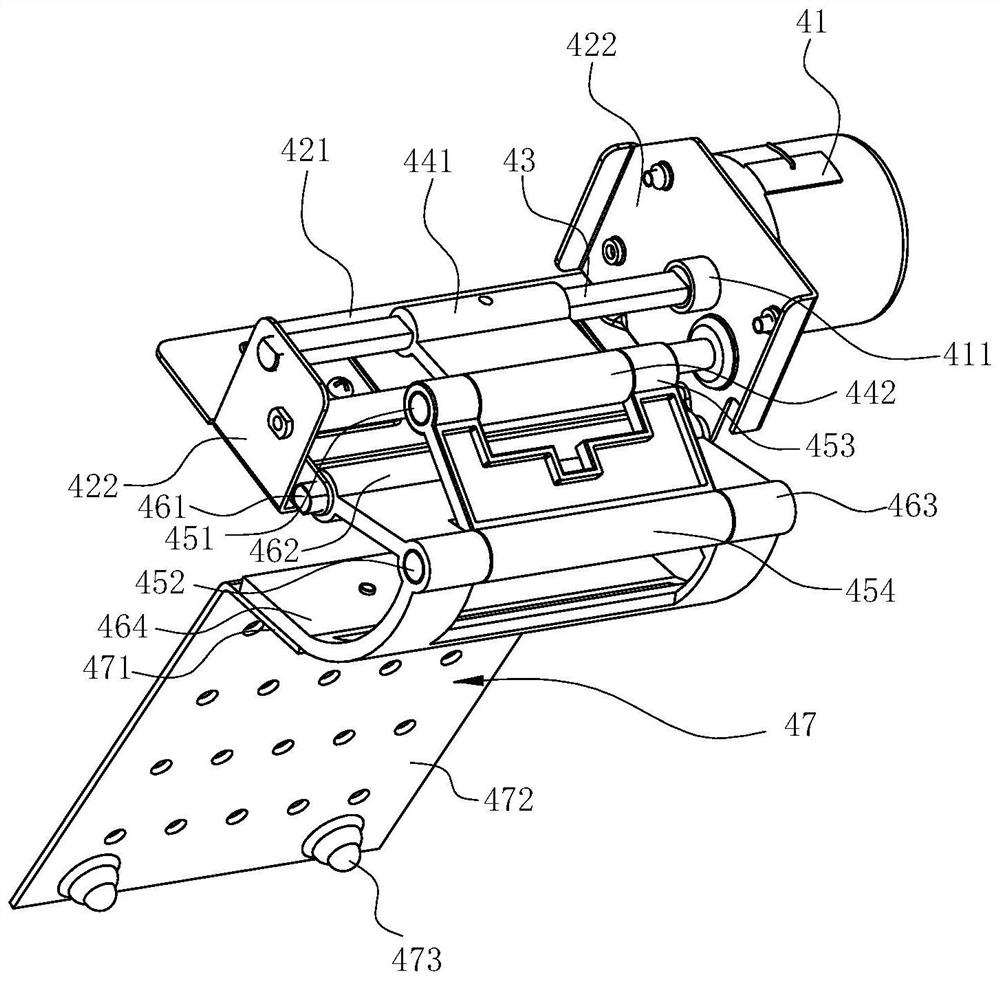

[0026] There is an air inlet 21 on the panel 2, and the upper end of the smoke baffle 3 is hinged to the panel 2, and the smoke baffle 3 rotates relative to the panel 2 by driving a transmission mechanism, so that the air inlet 21 can be opened or closed. The panel 2 includes a first panel 22 located above the smoke baffle 3 , and a second panel 23 located below the smoke baffle 3 , and the above-mentioned air inlet 21 is formed between the first panel 22 and the second panel 23 .

[0027] The above-mentioned drive tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com