Measuring device for measuring size of plunger ring and using method thereof

A measuring device and measuring column technology, which is applied in the direction of mechanical diameter measurement, etc., can solve the problems of difficulty in finding the highest point of the arc surface, inaccurate measurement, etc., and achieve the effect of ensuring measurement accuracy, accurate measurement results, and precise position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

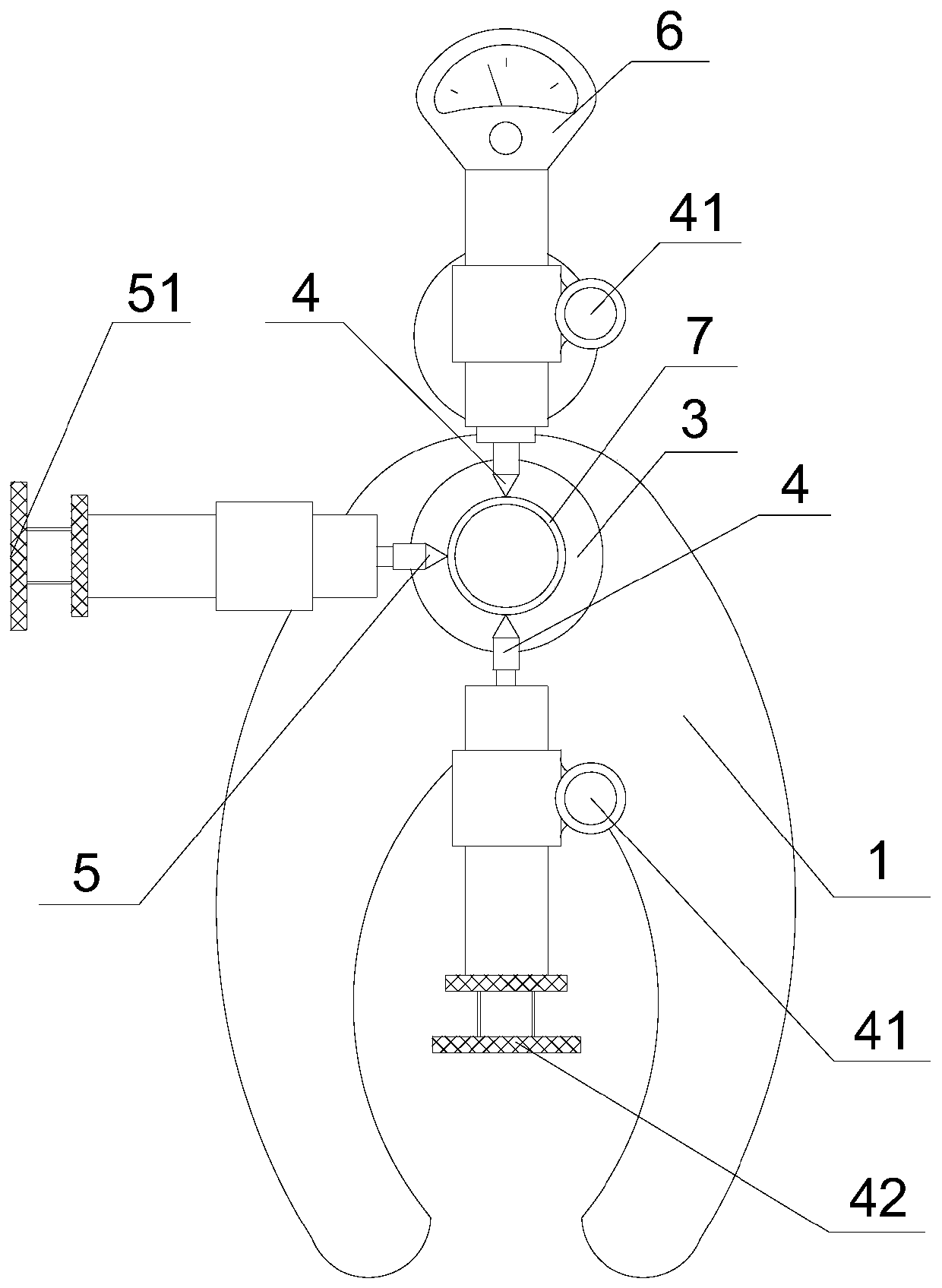

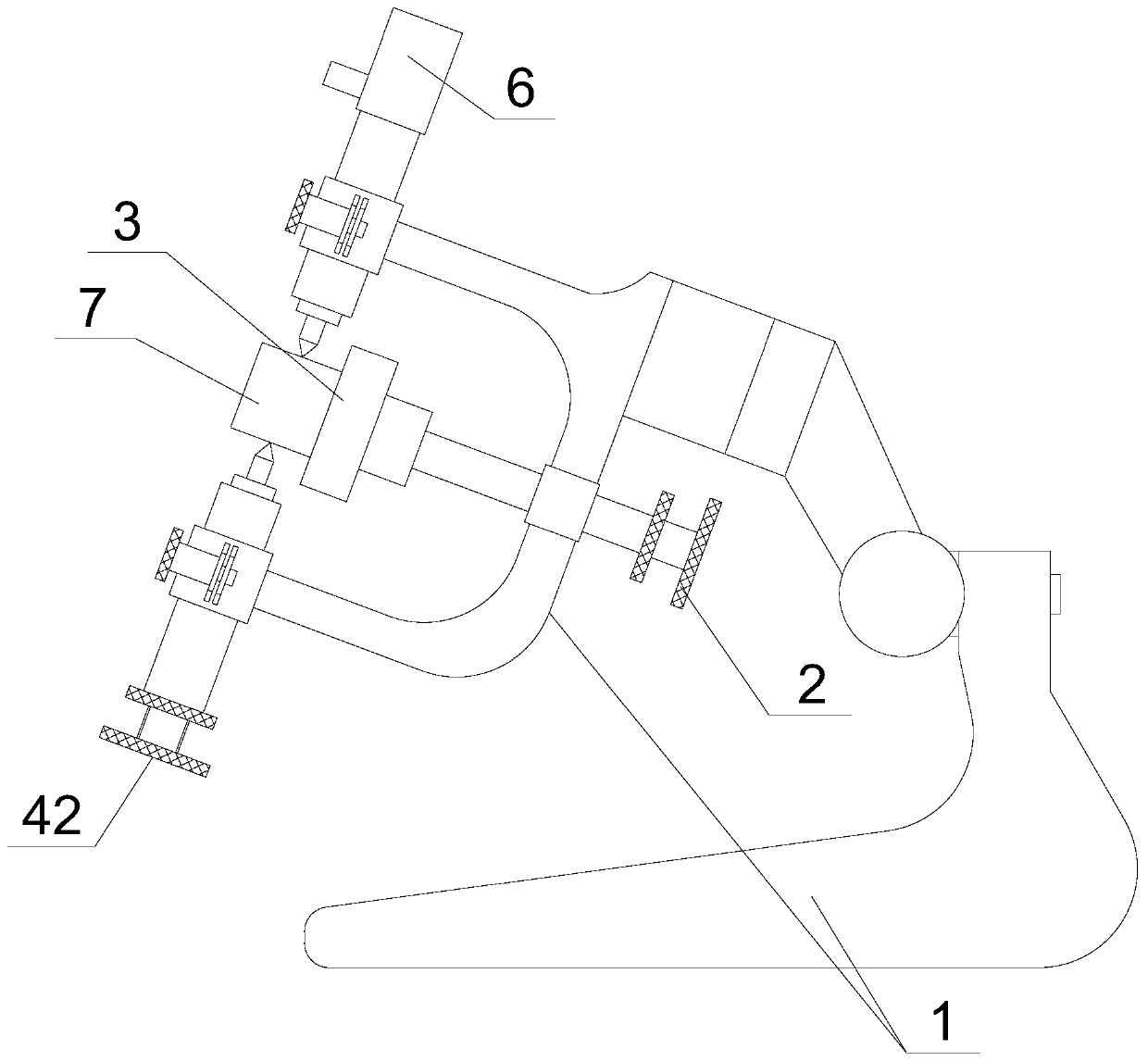

[0024] see Figure 1 to Figure 2 , the figure shows a measuring device for measuring the dimensions of a plunger ring, comprising:

[0025] a fixed seat 1;

[0026] A platform 3, which is installed on the fixed seat 1 through a platform adjusting screw 2 for adjusting its front and rear positions;

[0027] Two first styli 4 located directly above and directly below the platform 3, each first stylus 4 is installed on the fixed seat 1 through a longitudinal adjustment screw 41 for adjusting its longitudinal position;

[0028] A second measuring needle 5 installed on the fixed base 1 and located on the left side of the platform 3, and the second measuring needle 5 adjusts the lateral position through a first fine adjustment screw 51 connected to its rear end; and

[0029] A measuring gauge 6 installed on the fixed seat 1, and the measuring gauge 6 is connected with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com