Pressurizing device

A pressurizing device and a technology for installing holes, which are applied in textiles, papermaking, fabric surface trimming, etc., can solve problems such as increasing pressure, and achieve the effects of increasing pressure, simple structure, and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

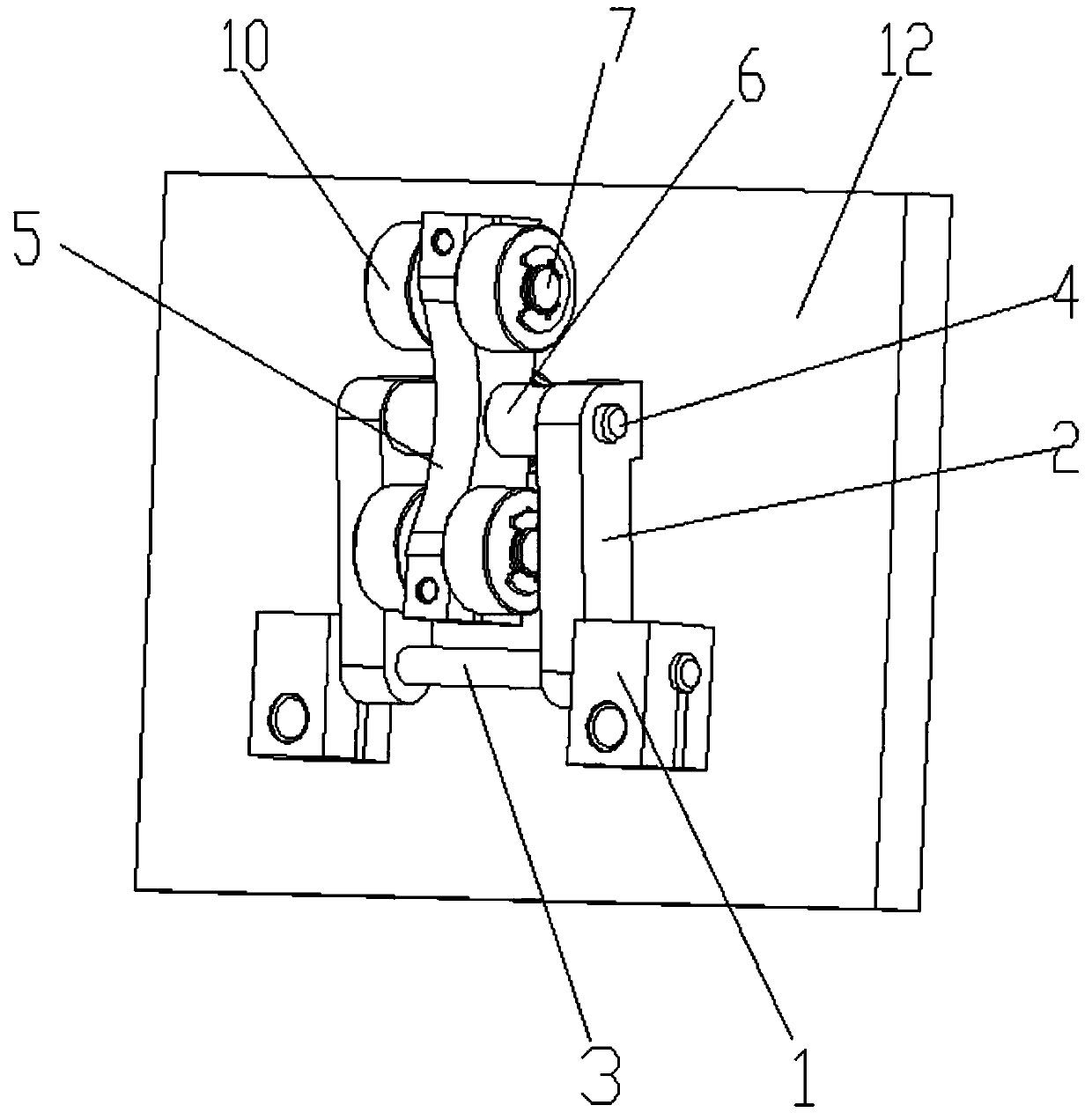

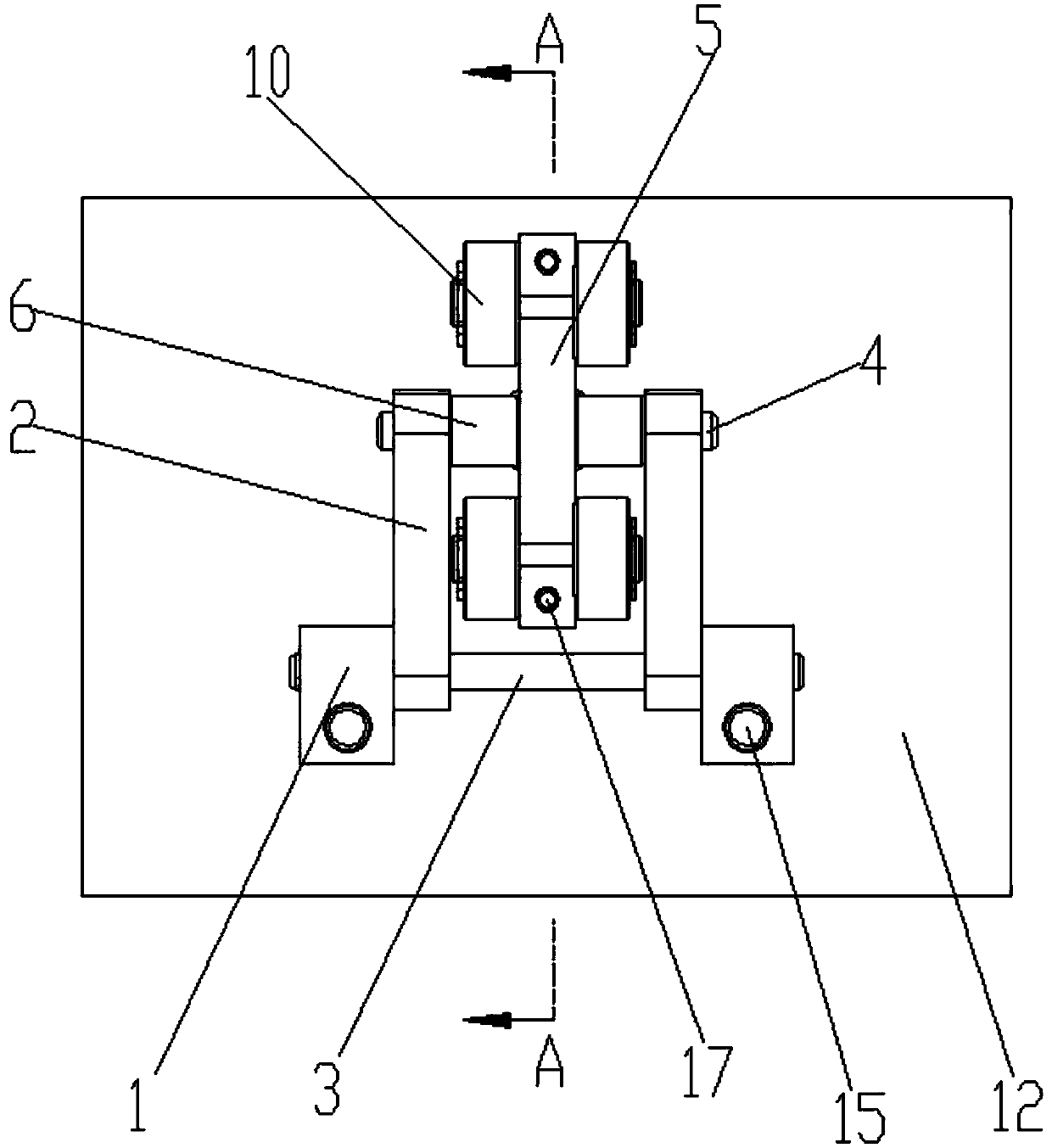

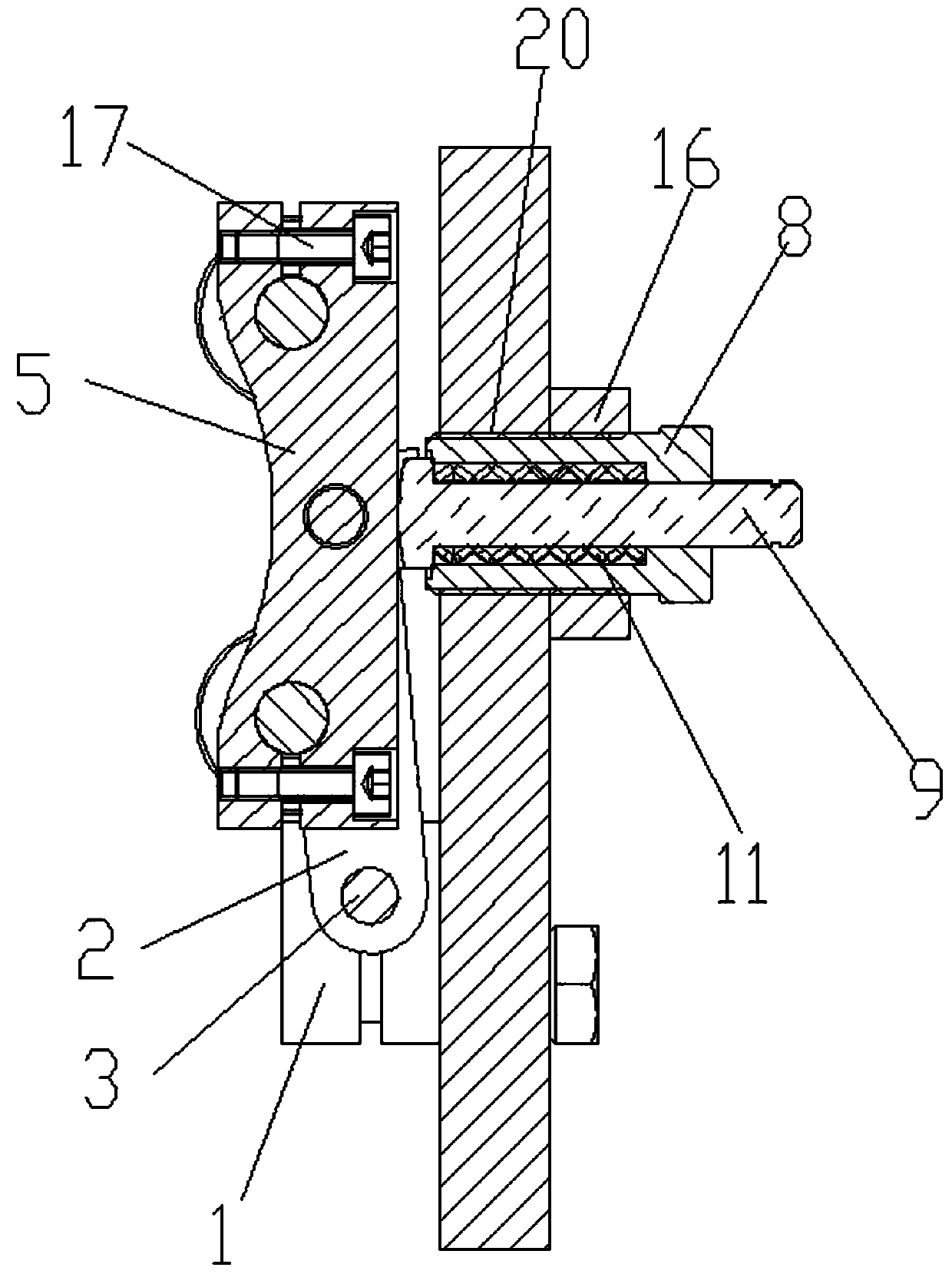

[0019] Attached below Figure 1-7 The embodiments of the present invention are described in detail.

[0020] A pressurizing device, comprising a fixed plate 12, two fixed blocks 1 are arranged on the fixed plate 12, the two fixed blocks 1 are symmetrically arranged left and right, the fixed blocks 1 are fixed on the fixed plate 12 by bolts 15, the two fixed blocks 1 A fixed shaft 3 is installed between them, and two rocker arms 2 are arranged to rotate on the fixed shaft 3, and a rocker shaft 4 is installed on the end of the rocker arm 2 away from the fixed shaft 3, and a bearing bracket 5 is installed at the middle position of the rocker shaft 4, and the bearing bracket The frame 5 can rotate around the rocker shaft 4, and the rocker shaft 4 is covered with two sleeves 6, which are respectively located between the bearing bracket 5 and the two rocker arms 2, and the two ends of the bearing bracket 5 are equipped with roller shafts 7, and the rollers Both sides of the shaft 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com