Bridge beam plate hoisting position reinforcing steel bar accurate arrangement technology

A precise technology for positioning steel bars, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the collision of steel bars and beams and slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Shown in conjunction with accompanying drawing, the technical scheme of the present invention is further described:

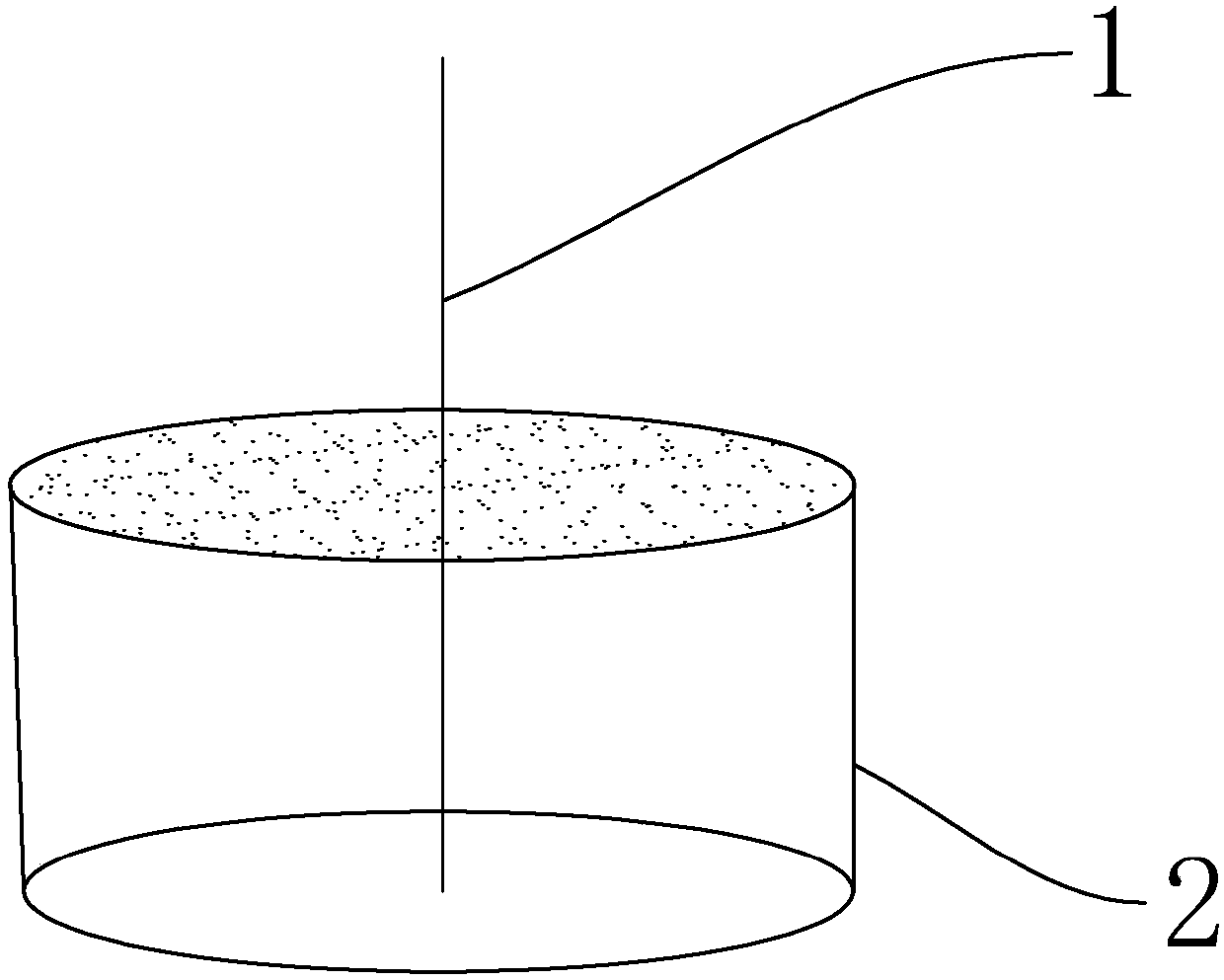

[0020] A bridge girder slab hoisting and positioning steel bar precise placement technology, including positioning steel bar 1, a drum 2, the drum 2 is a hollow drum, and the drum 2 does not include a top surface and a bottom surface;

[0021] The precise placement technology of the positioning reinforcement includes the following steps:

[0022] S1: place the drum 2 at the fixed position where the steel bars need to be positioned;

[0023] S2: Pouring concrete into the drum 2 to fill up the drum 2;

[0024] S3: After the concrete fills the drum 2, quickly insert the steel bar 1 into the concrete of the drum 2, and the insertion position of the steel bar 1 is the position that needs to be accurately positioned.

[0025] In this embodiment, it is preferable to select the inner diameter of the drum 2 to be 5-10 cm, and the height of the drum body 2 to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com