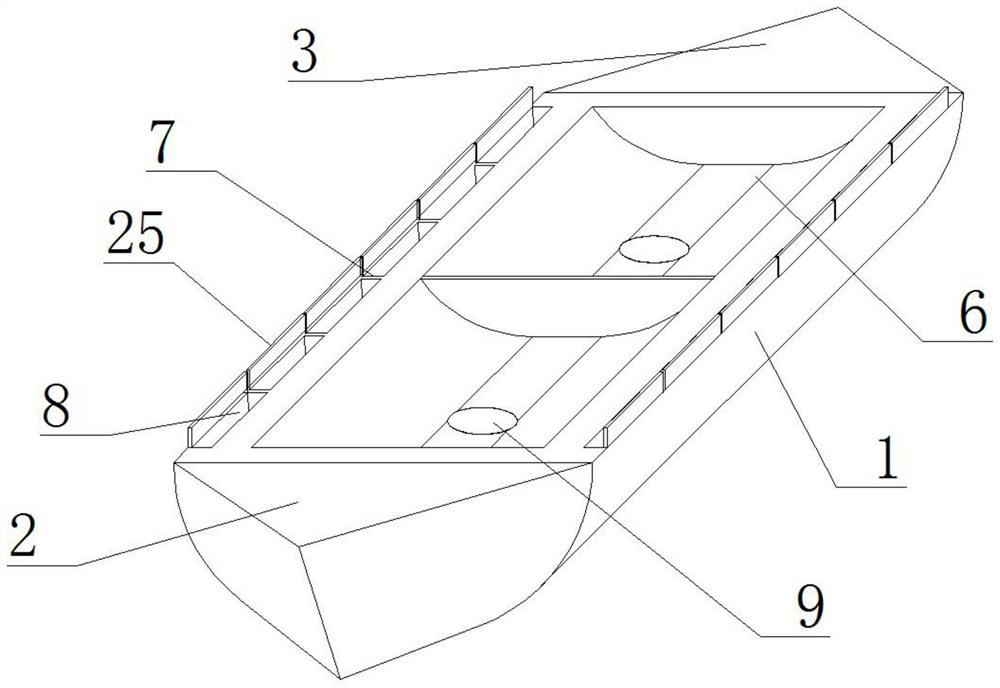

An automated ship for transporting rocks and filling the sea

一种电动、船尾的技术,应用在机动车、船只建造、船舶推进等方向,能够解决增加石块倾倒时间、增加船头重量、能源浪费等问题,达到提高下落的速度、减少设备的投入、提高卸料的速率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

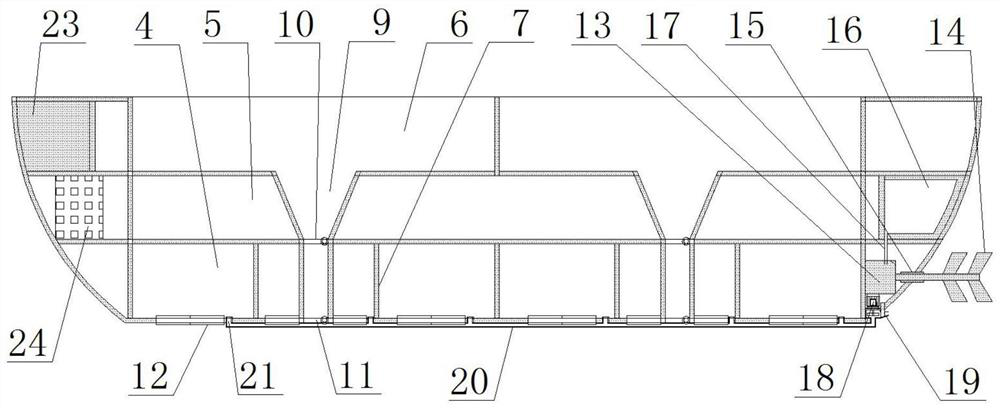

[0025] As a preferred embodiment of the present invention, the storage battery 24 is connected to the intelligent control room 23 through wires, and the intelligent control room 23 is connected to the electric airtight door one 10, the electric airtight door two 11, the electric airtight door three 12, Electric sealing door four 25, engine 13, solenoid valve one 19, solenoid valve two 21 and water pump 18 are connected.

[0026] As a preferred embodiment of the present invention, a water outlet pipe is welded on one side of the water pump 18 , and the water pump 18 communicates with the water outlet pipe through a solenoid valve one 19 .

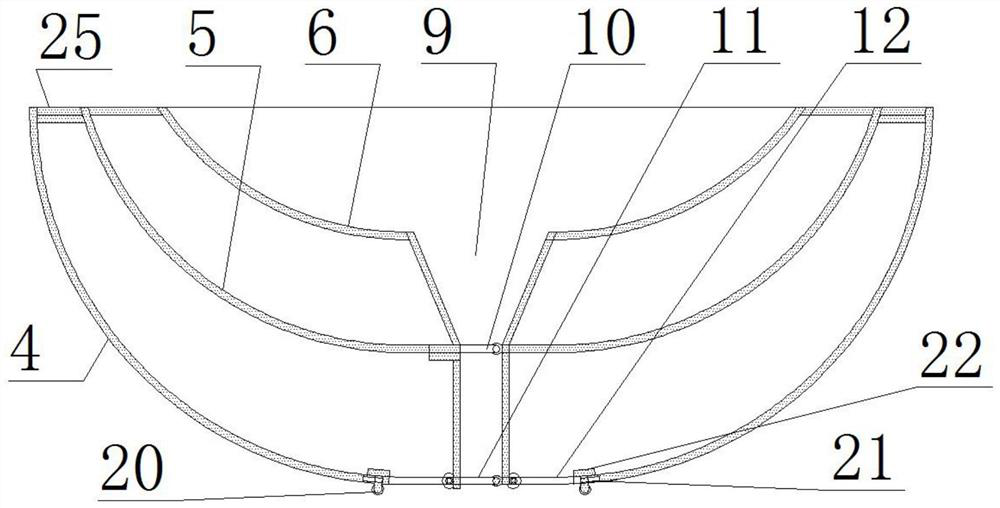

[0027] As a preferred embodiment of the present invention, the bottom of the lower layer 4 is provided with a water outlet, the solenoid valve 2 21 is installed inside the water outlet, the water pipe 20 communicates with the lower layer 4 through the water outlet, and the filter screen 22 are welded on the top of the water port.

[0028] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com