Feeding structure and feeder

A feeder and material feeding technology, which is applied in the field of feeding structure and feeder, can solve the problems of material leakage, material jam, particle material leakage, etc., and achieve the effect of solving the problem of material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

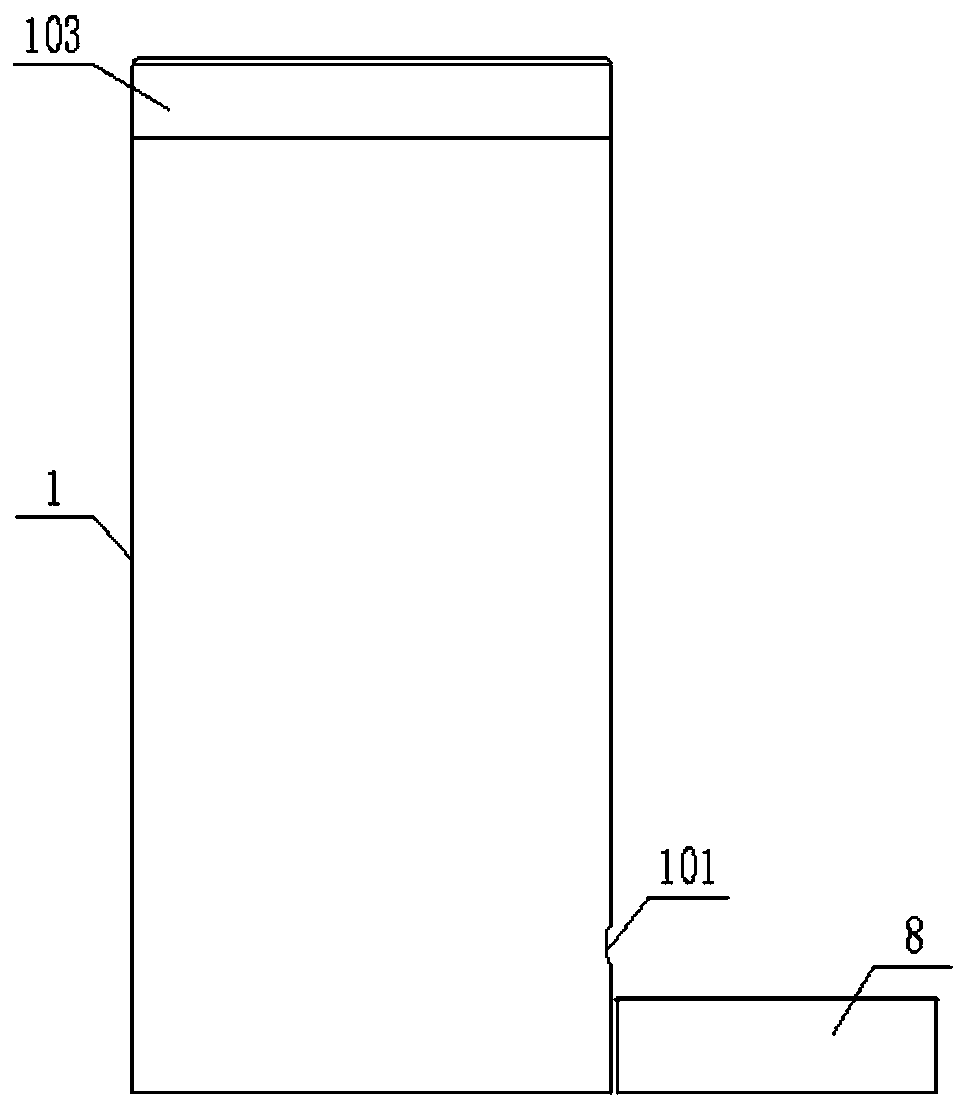

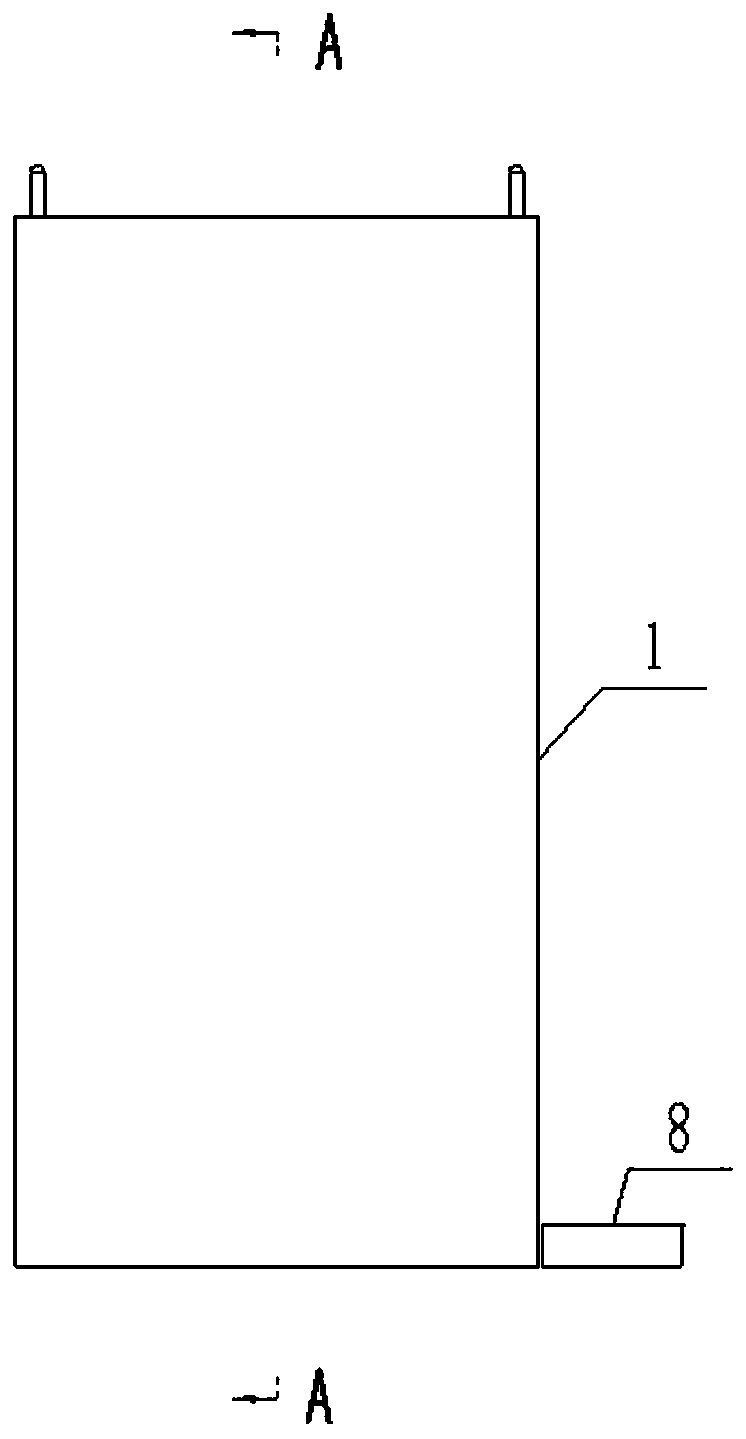

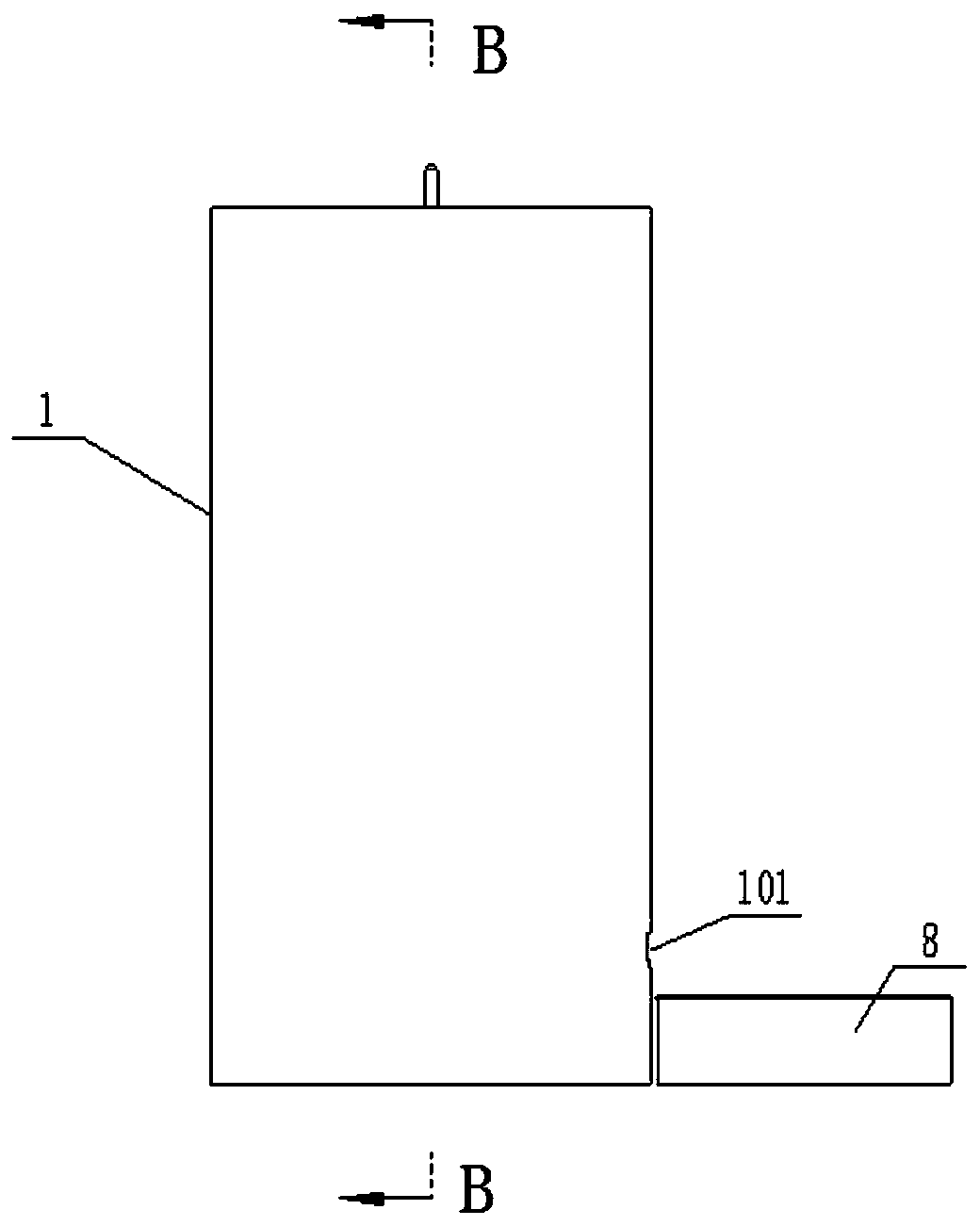

[0032] Such as Figures 1 to 6 As shown, a feeding structure includes a first cylinder body 1, a second cylinder body 2, a lifting disk 4 and a driving mechanism.

[0033] The lower part of the first cylinder 1 is provided with a discharge port 101, the upper end of the first cylinder 1 is open, the height of the first cylinder 1 is less than or equal to the height of the second cylinder 2, and an upwardly protruding end cap is installed on the opening 103 and the highest point of the end cover 103 is slightly higher than the second cylinder body 2, the end cover 103 has a restrictive effect on the material exposed from the upper end of the second cylinder body 2, so that the material can enter the material from the second cylinder body 2 The channel 3 will not spill out of the first cylinder 1; the first cylinder 1 is connected with a cross brace 102, and the cross brace 102 is fixedly connected with the upper end of the second cylinder 2.

[0034] Both ends of the second cy...

Embodiment 2

[0038] Such as Figures 1 to 6 As shown, a feeding structure includes a first cylinder body 1, a second cylinder body 2, a lifting disk 4 and a driving mechanism.

[0039] The lower part of the first cylindrical body 1 is provided with a discharge port 101, and one end of the first cylindrical body 1 is open, and the height of the first cylindrical body 1 is greater than the height of the second cylindrical body 2. At this time, the end cap 103 may not be installed, and the material Generally also can not be spilled out, also can install flat end cap 103 or the end cap 103 that protrudes upwards, has a restricting effect to the material that comes out from the second barrel 2 upper opening, can guarantee like this material from the second cylinder The body 2 enters the material channel 3 without spilling out of the first cylinder body 1; the first cylinder body 1 is connected with a cross brace 102, and the cross brace 102 is fixedly connected with the upper end of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com