A high-speed permanent magnet motor rotor with integrated shaft sleeve and assembly method

A permanent magnet motor and assembly method technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems affecting the stability of the motor rotor structure and the decrease of the overall rigidity of the rotor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

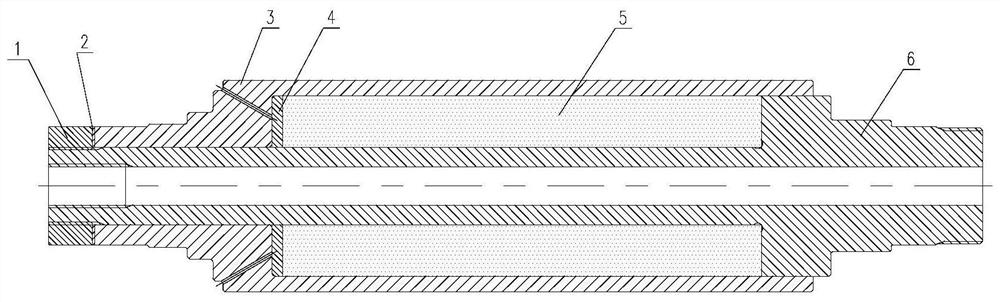

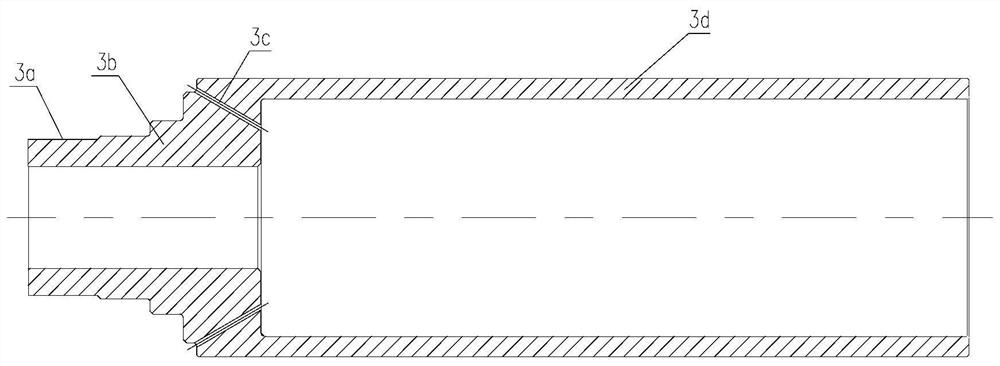

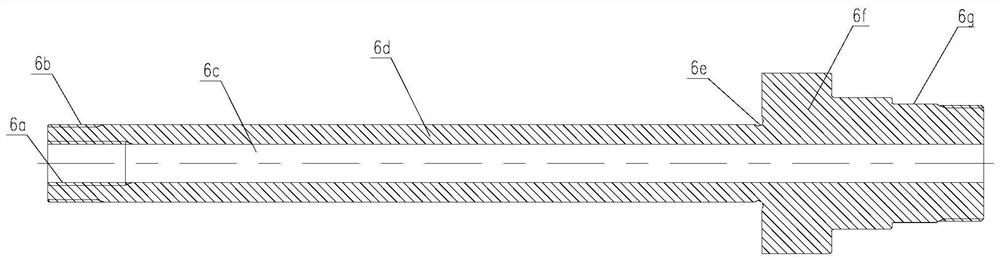

[0013] Detailed description: The rotor of a high-speed permanent magnet motor is as attached figure 1 As shown, it is composed of a lock nut 1, a disc spring 2, a shaft sleeve 3, a magnetic steel end cover 4, a magnetic steel 5, and a mandrel 6, and the structure is simple. First, assemble the magnetic steel 5 on the mandrel 6, apply adhesive on the joint surface, and then assemble the magnetic steel end cover 4 on the mandrel 6, so that the The right end surface of the magnetic steel end cover 4 is bonded to the left end surface of the magnetic steel 5, and the joint surface is coated with adhesive to form a combination. Then, the shaft sleeve 3 is heated and fitted on the outside of the assembly, and an interference fit is used between the shaft sleeve 3 and the assembly. Finally, install the disc spring 2 and lock nut 1 in turn on the left end of the mandrel 6, and during the process of tightening the lock nut 1, the disc spring 2 will generate a certain amount of compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com