Motor controller heat dissipation protection device

A motor controller and protective device technology, applied in electrical components, rack/frame structure, electrical equipment structural parts, etc., can solve the problems of heat generated by operation, temperature rise around the motor controller, loss of the motor controller, etc. Achieve the effect of improving high temperature air flow, improving service life and facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

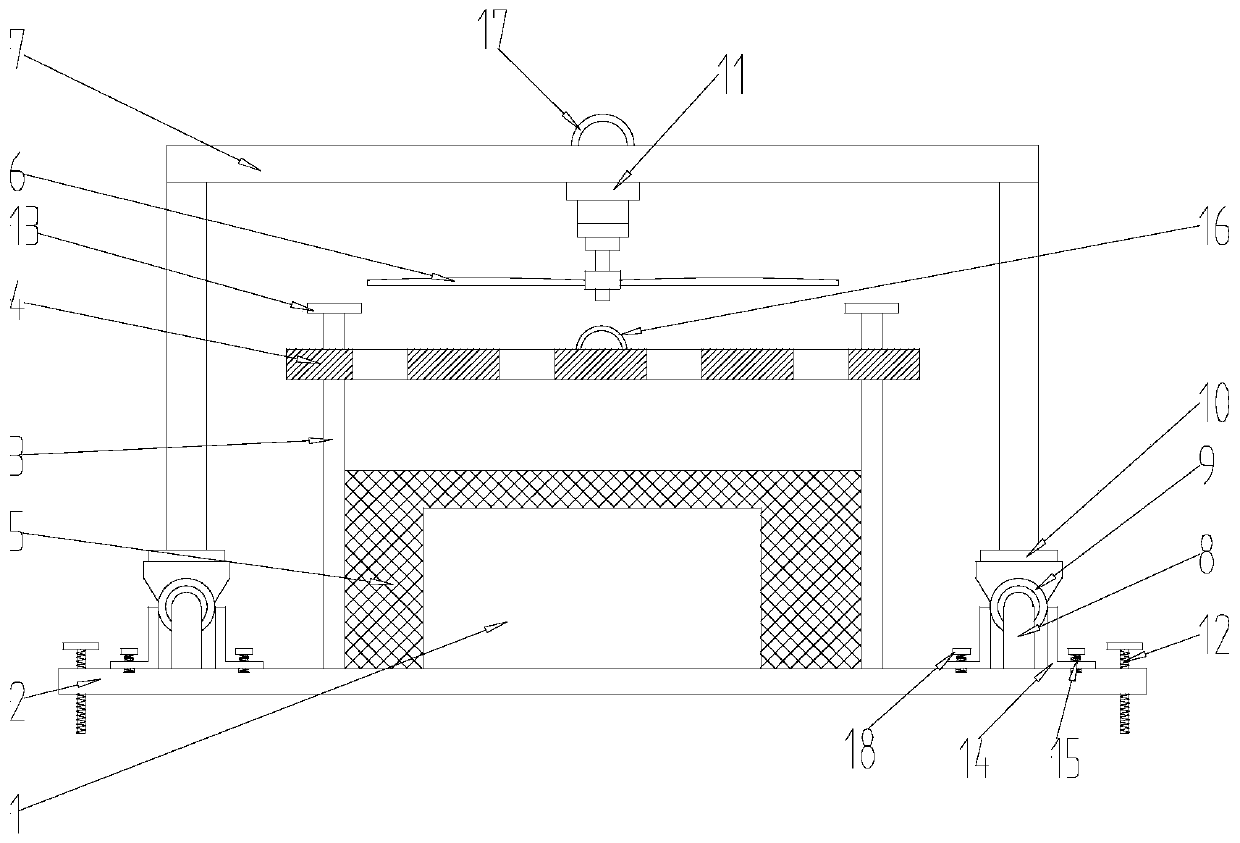

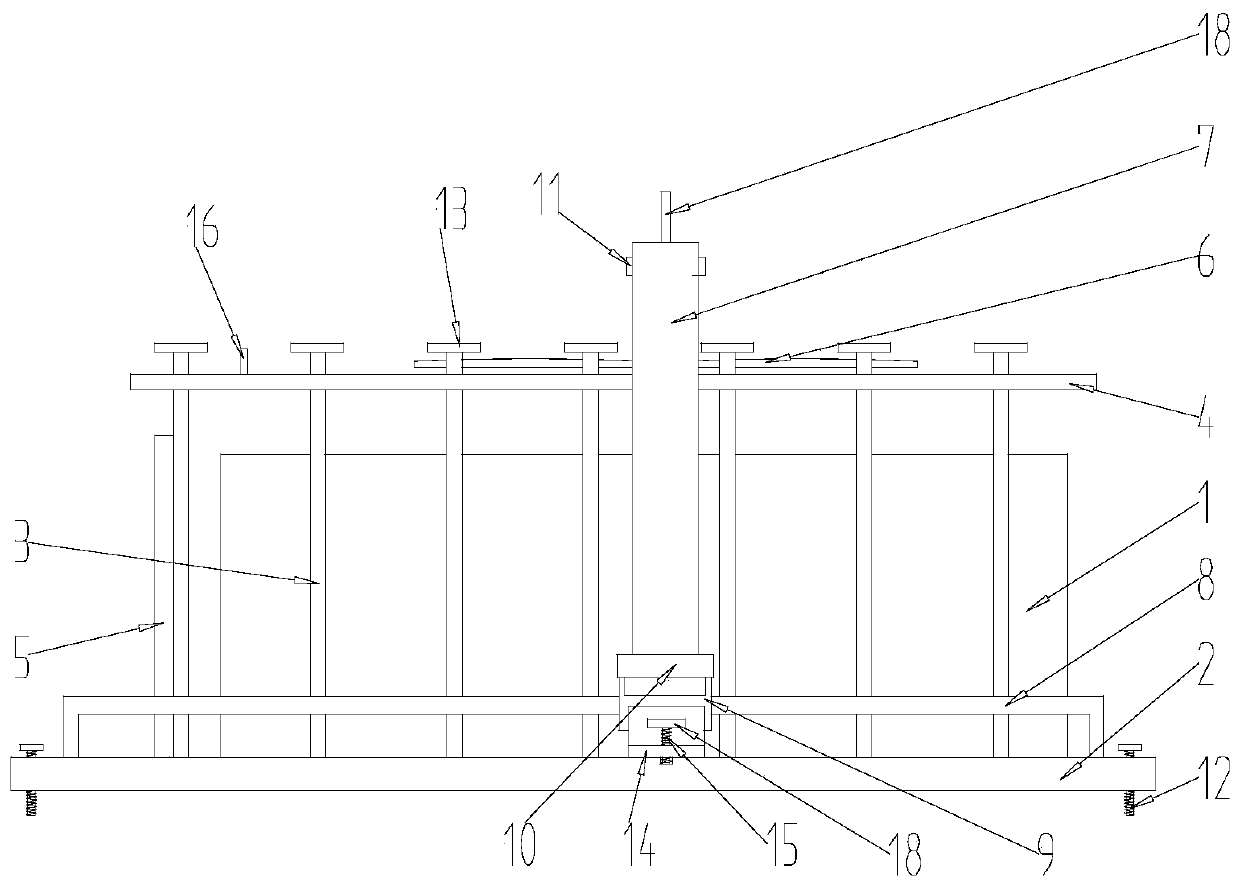

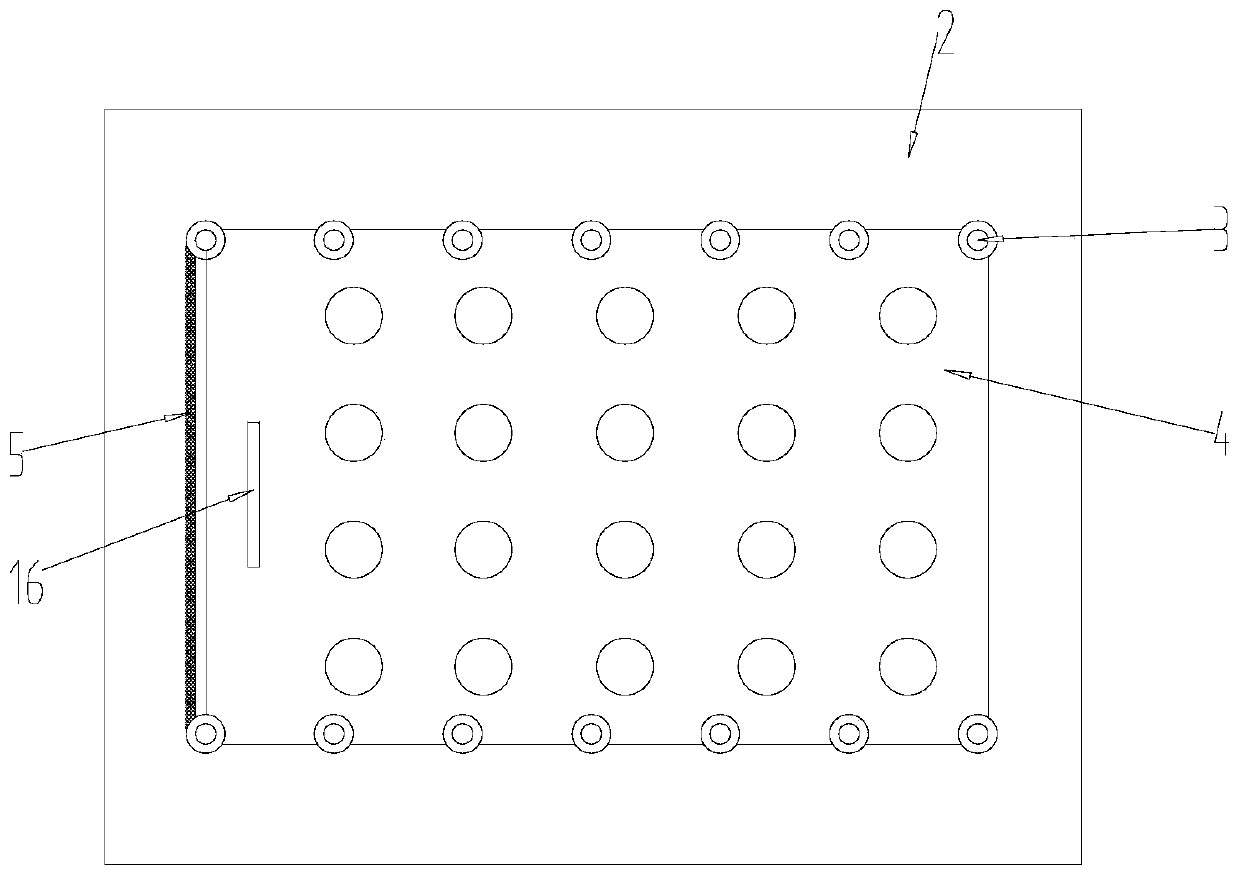

[0025] Embodiment: All electrical components in this case are connected to their adapted power supply through wires by persons skilled in the art, and an appropriate controller should be selected according to the actual situation to meet the control requirements. For the specific connection and control sequence, please refer to the following In the working principle described above, the electrical connection between the electrical parts is completed in sequence. The detailed connection means is a well-known technology in the field. The following mainly introduces the working principle and process, and does not explain the electrical control. When in use, the support The screw 12 on the first threaded port on the seat 2 is convenient for reasonable installation of the device, and then the motor controller 1 is conveniently installed and placed on the upper wall of the support 2, and then when the motor controller 1 is installed, the baffle 4 is pulled, and the baffle 4 can move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com