Vacuum pressure impregnation system and operation method

A technology of vacuum pressure impregnation and pressurization system, which is applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of easy introduction of impurities, poor insulation performance of impregnating liquid products, etc., to improve product quality and performance. and indicators, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

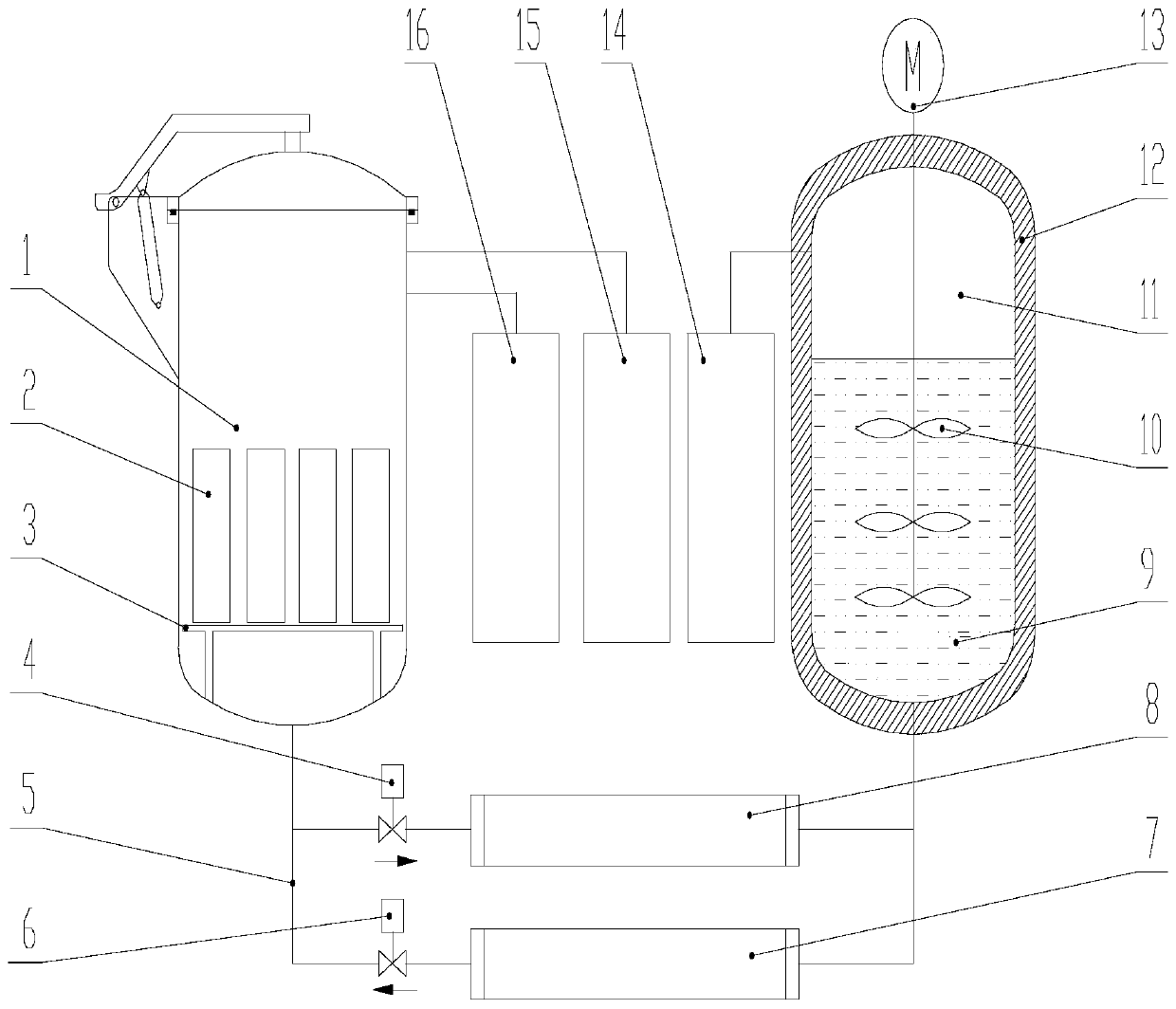

[0027] Such as figure 1 As shown, the present embodiment provides a vacuum pressure impregnation system, which mainly includes a dipping tank 1 and a liquid storage tank 11; wherein, the interior of the dipping tank 1 is provided with a tray 3, and the workpiece 2 is placed on the tray 3, and the outside of the dipping tank 1 passes The pipeline is connected to the evacuation system 15 of the dipping tank and the pressurization system 16 of the dipping tank; The interior of 11 is provided with dipping liquid 9, stirring anchor 10, and the top of liquid storage tank 11 is provided with stirring motor 13 and is connected with internal stirring anchor 10; The road 5 is connected, and the infusion and return pipeline 5 is connected in parallel with the infusion pipeline and the liquid return pipeline: the infusion valve 6 and the infusion filter 7 are arranged on the infusion pipeline, and the liquid return valve 4 and the liquid return pipeline are arranged on the liquid return p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com