Method for preparing methyl tetrahydrophthalic anhydride and synthesis system

A technology of methyltetrahydrophthalic anhydride and maleic anhydride, applied in the field of preparation of methyltetrahydrophthalic anhydride, method and synthesis system, can solve the problem of decreased reaction rate and prolongation of the operation time of C5 in petroleum fractions , low conversion rate of maleic anhydride, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] Examples of Preparation of Raw Materials and / or Intermediates

[0071] Raw material 1: Petroleum fraction C5 (from Sinopec Shanghai Petrochemical Co., Ltd.), including isoprene and piperylene.

[0072] Isoprene, chemical name: 2-methyl-1,3-butadiene

[0073] Molecular formula: C 5 h 8

[0074] Quality Standard: Chemical Research Institute of Sinopec Shanghai Petrochemical Co., Ltd.

[0075] Standard number: Industrial isoprene SH / T 1781-2016

[0076] Piperylene, chemical name: 1,3-pentadiene or pentadiene

[0077] Molecular formula: C 5 h 8

[0078] Quality Standard: Chemical Research Institute of Sinopec Shanghai Petrochemical Co., Ltd.

[0079] Standard number: Industrial piperylene SH / T 1791-2015

[0080] Raw material 2: maleic anhydride (from Ningbo Zhetie Jiangning Chemical Co., Ltd.), maleic anhydride for short.

[0081] Molecular formula: C4H2O3

[0082] Structural formula:

[0083] Properties: white massive or flaky crystals. Has a pungent odor. ...

Embodiment 1

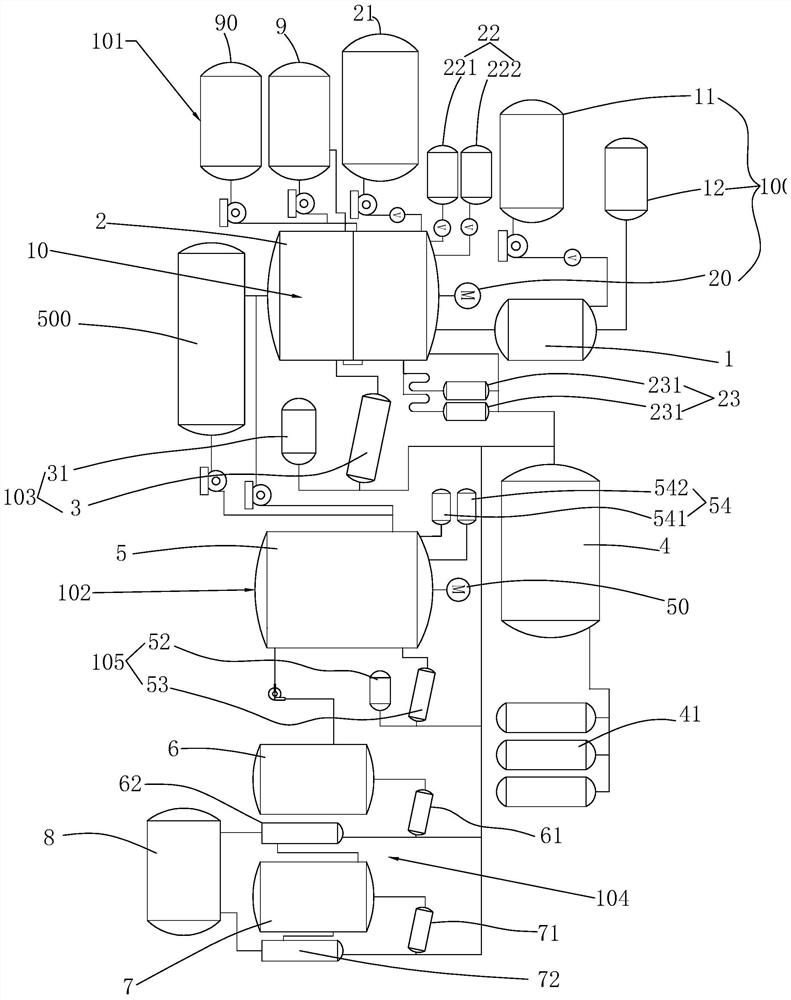

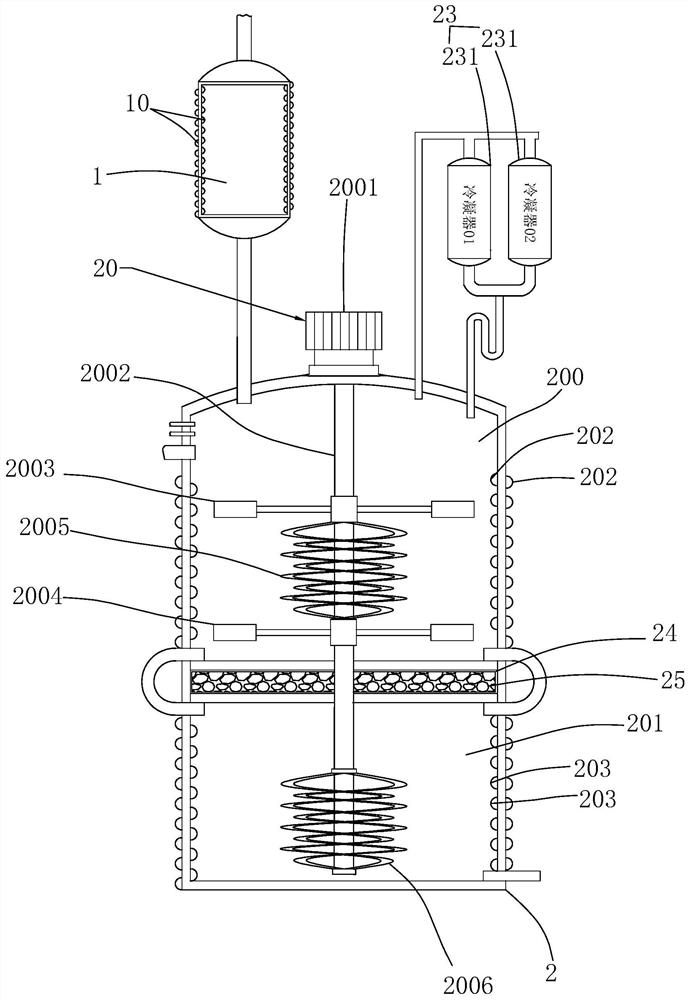

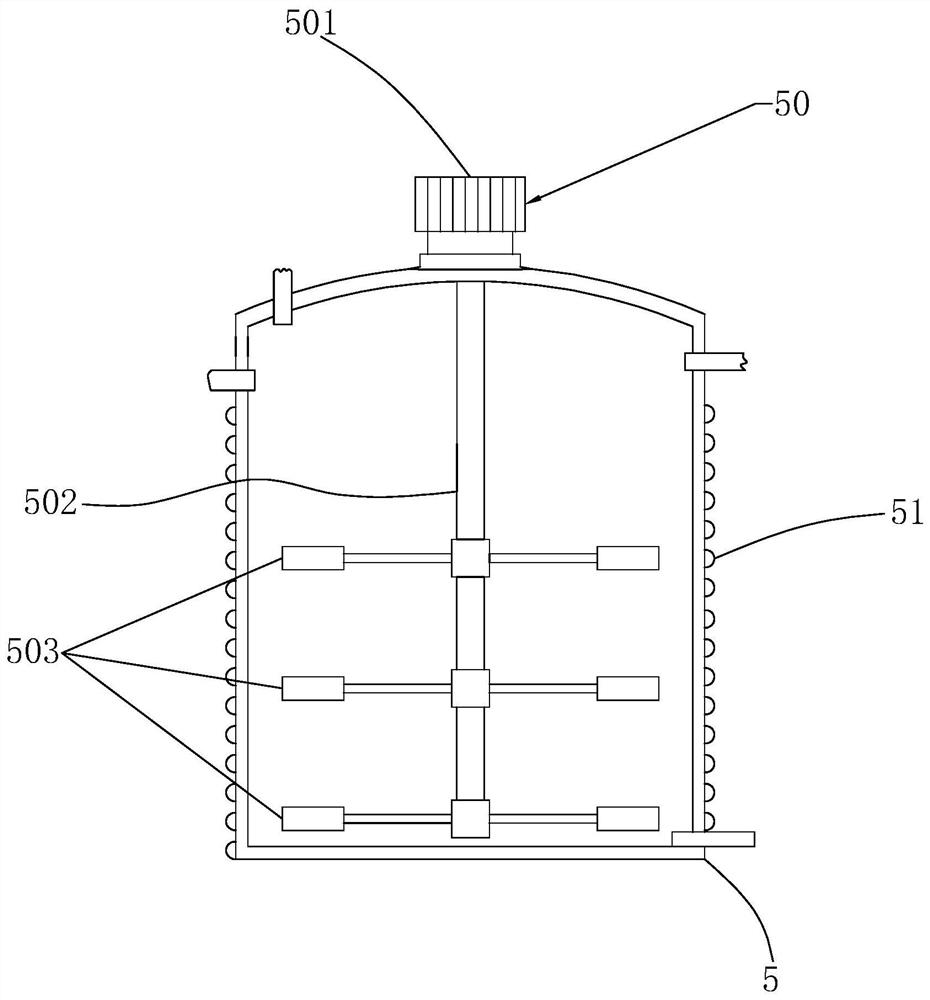

[0088] refer to figure 1 , a synthesis system for preparing methyltetrahydrophthalic anhydride, comprising a maleic anhydride pre-treatment device 100, the maleic anhydride pre-treatment device 100 includes a maleic anhydride metering tank 1, and the top of the maleic anhydride metering tank 1 is communicated with a device placed on the ground The maleic anhydride storage tank 11, the maleic anhydride stored in the maleic anhydride storage tank 11 has been heated and melted to become a liquid, and is transported to the maleic anhydride metering tank 1 through a chemical pump, and is connected with the maleic anhydride storage tank 11 and the maleic anhydride metering tank 1 The flow meter on the tube is used to accurately measure the amount of maleic anhydride required. The top of the maleic anhydride metering tank 1 is connected with a nitrogen tank 12. After the maleic anhydride metering tank 1 is pumped into the maleic anhydride, the nitrogen in the nitrogen tank 12 is pass...

Embodiment 2

[0096] A kind of method for preparing methyltetrahydrophthalic anhydride disclosed by the invention, the specific operation steps are as follows:

[0097] Step 1: raw material pretreatment;

[0098] Step 1.1: For the pretreatment of maleic anhydride, use the flow meter installed on the connecting pipe between the maleic anhydride storage tank 11 and the maleic anhydride metering tank 1 to accurately measure the required maleic anhydride, and transport the maleic anhydride with the correct measurement through the chemical pump In the maleic anhydride metering tank 1; the nitrogen in the nitrogen gas tank 12 is continuously passed into the maleic anhydride metering tank 1, and the air inside the maleic anhydride metering tank 1 is driven out; steam is passed into the first coil 10 to heat the maleic anhydride , so that the temperature of maleic anhydride is controlled at 55°C, P=100Kpa, and kept warm for later use;

[0099] Step 1.2: pretreatment of petroleum fraction C5, step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com