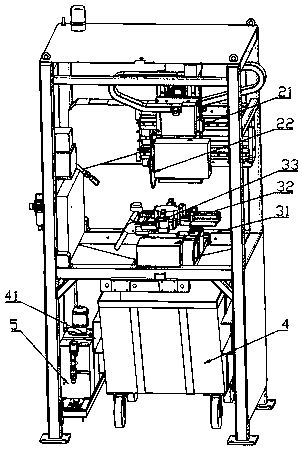

Full-automatic sawing machine

A sawing machine, fully automatic technology, applied in the field of automation, can solve the problems of insecure personal safety, easy fatigue of manual operation, easy breaking of band saw blades, etc., so as to avoid personal injury, solve table saw vibration, and avoid vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

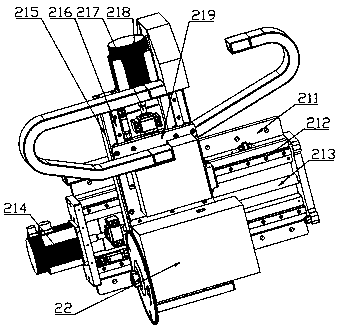

[0051] Embodiment 2 is different from Embodiment 1 in that the external manipulator also clamps the product protection shell 71 and buckles it on the product, and the product with the product protection shell 71 is only partially exposed, preventing the product from being sawed during the cutting process. Chips pollute the product, eliminating the need for cleaning after cutting the product.

[0052] The product protective shell 71 is set in a metal box, and a groove is arranged in the protective shell. The groove matches the product, and the product is embedded in the groove. The horizontal push cylinder pushes the protective shell of the inner button product to be embedded in the block 322 and against the product, the movable end of the corner cylinder is rotated 90 degrees and pressed down to press the two sides of the protective shell of the inner buckle product to realize the fixation of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com