Flexible generated packaged process base for rail transit industry

An industry-leading and flexible technology, applied in the field of complete process bases, can solve problems such as reducing the check time of returned parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

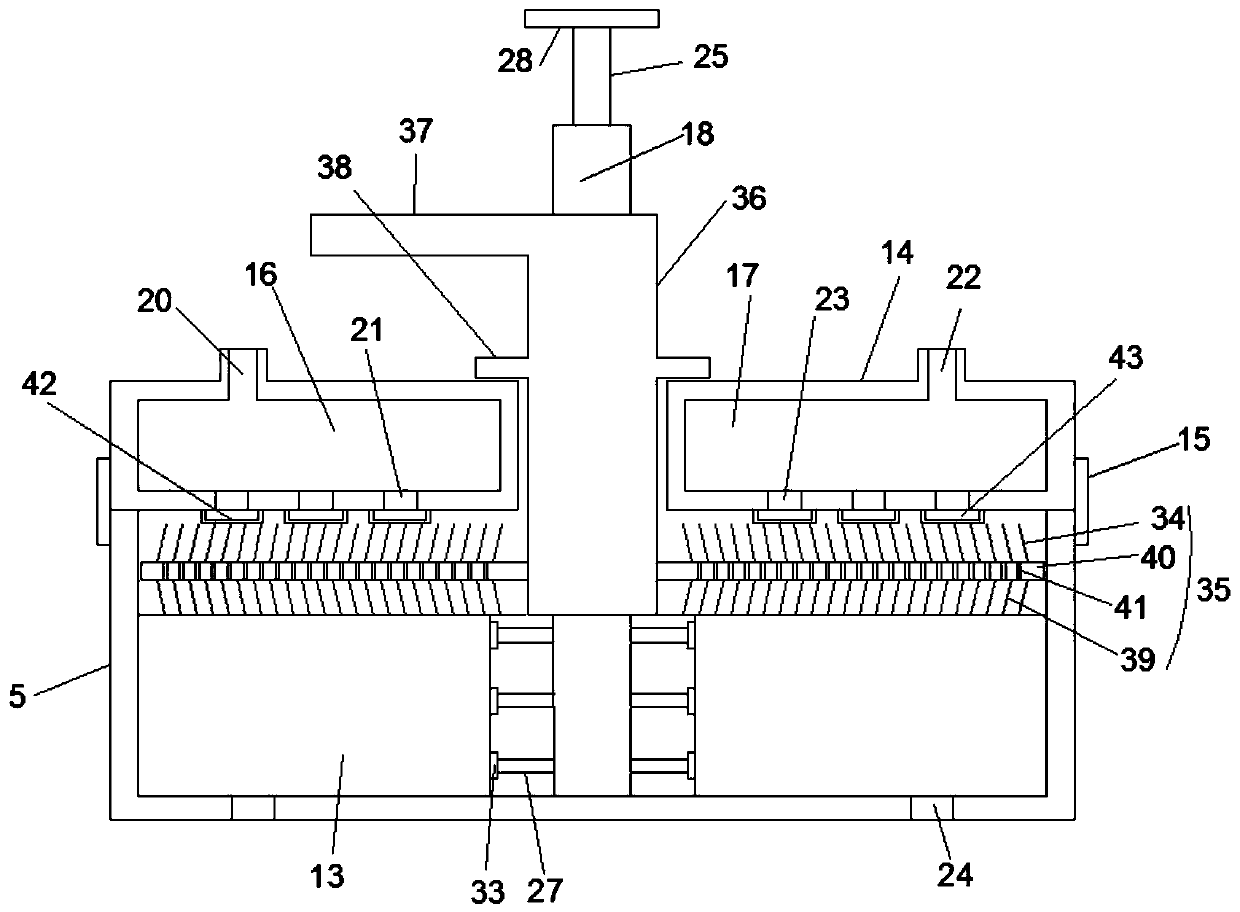

[0096] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

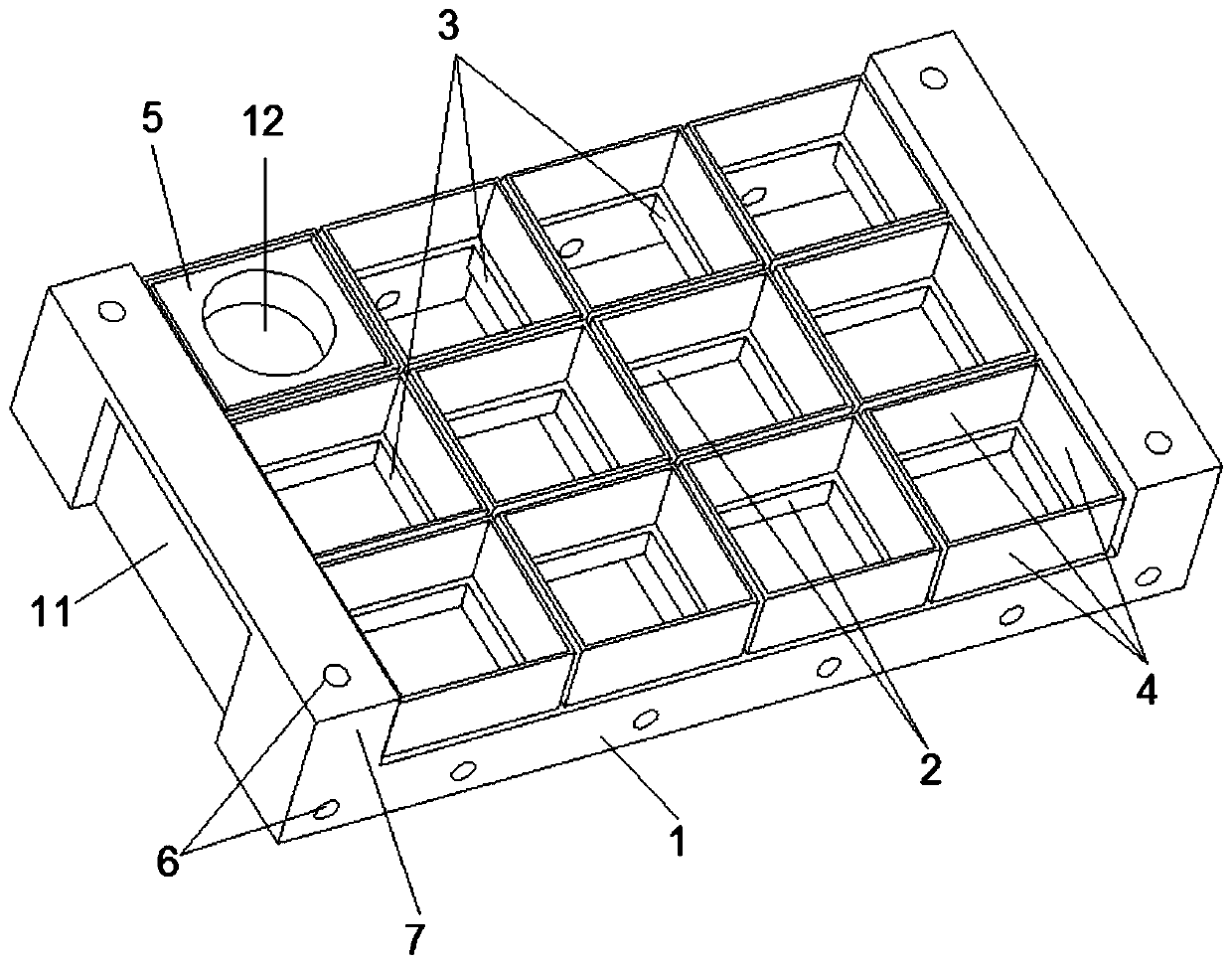

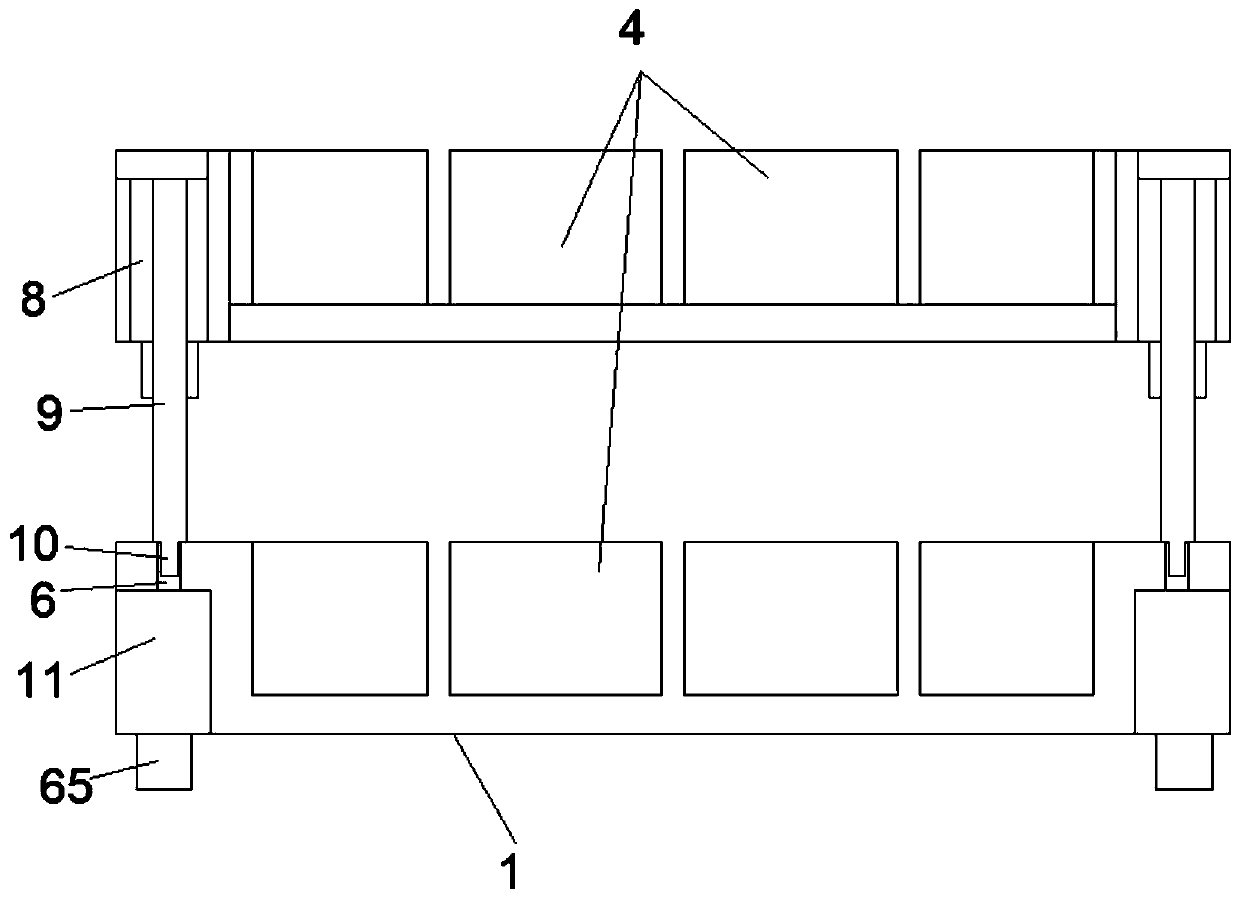

[0097] according to figure 1 As shown, a complete set of process base for flexible generation used in rail transit industry, including: frame 1, beam 2 and vertical beam 3,

[0098] The frame 1 is a square frame structure formed through the center of a square plate, and a plurality of crossbeams 2 are horizontally spaced in the square frame structure, and a plurality of vertical beams 3 are vertically spaced apart,

[0099] Each of the crossbeams 2 and the vertical beams 3 defines a plurality of seat holes of a square structure in the square frame structure,

[0100] The top surface of each seat hole is provided with an upwardly extending fence plate 4, and the fen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com