A Kinematic Mechanism with Flexible and Variable Rigidity

A technology of motion mechanism and drive mechanism, which is applied in the field of power manipulators, can solve the problems of small application range, insufficient flexibility of motion mechanism, and inability to realize rigidity flexible free transformation, etc., and achieve the effect of free switching and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

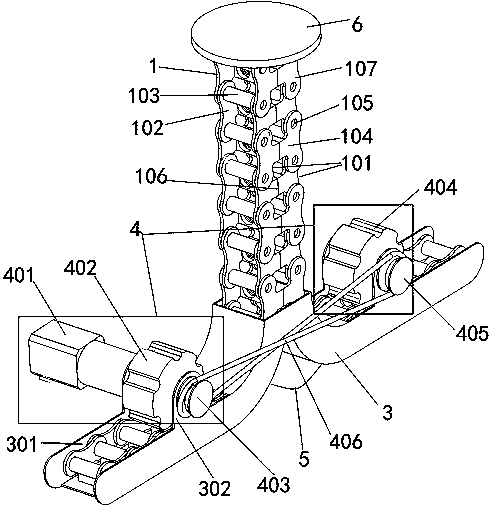

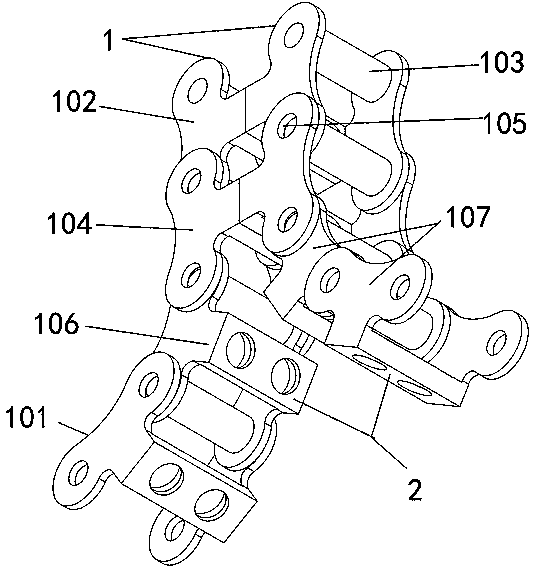

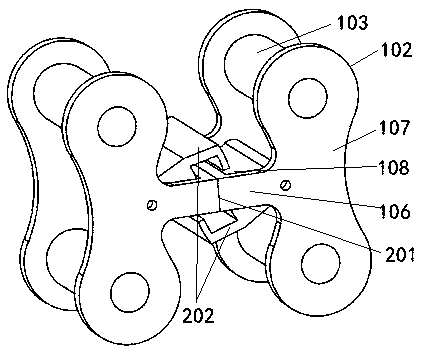

[0032] A kinematic mechanism with flexible and variable rigidity, comprising a kinematic chain 1 and a driving mechanism 4, the kinematic chain 1 moves through the driving mechanism 4, the kinematic chain 1 includes two symmetrically installed kinematic single chains 101, the kinematic single chain The chain 101 includes a number of inner sections 102 and a number of outer sections 104, the inner sections 102 and the outer sections 104 are composed of two joint pieces 107, and two hinge base columns are arranged between the two joint pieces 107 of the inner section 102 103, there are two hinge base holes 105 penetrating between the two joint pieces 107 of the outer section 104, the hinge base column 103 at the lower end of the inner section 102 and the hinge base hole 105 at the upper end of the outer section 104 are movably installed, the The hinged base column 103 at the upper end of the inner section 102 and the hinged base hole 105 at the lower end of the other outer sectio...

Embodiment 2

[0042] A kinematic mechanism with flexible and variable rigidity, comprising a kinematic chain 1 and a driving mechanism 4, the kinematic chain 1 moves through the driving mechanism 4, the kinematic chain 1 includes two symmetrically installed kinematic single chains 101, the kinematic single chain The chain 101 includes a number of inner sections 102 and a number of outer sections 104, the inner sections 102 and the outer sections 104 are composed of two joint pieces 107, and two hinge base columns are arranged between the two joint pieces 107 of the inner section 102 103, there are two hinge base holes 105 penetrating between the two joint pieces 107 of the outer section 104, the hinge base column 103 at the lower end of the inner section 102 and the hinge base hole 105 at the upper end of the outer section 104 are movably installed, the The hinged base column 103 at the upper end of the inner section 102 and the hinged base hole 105 at the lower end of the other outer sectio...

Embodiment 3

[0052] A kinematic mechanism with flexible and variable rigidity, comprising a kinematic chain 1 and a driving mechanism 4, the kinematic chain 1 moves through the driving mechanism 4, the kinematic chain 1 includes two symmetrically installed kinematic single chains 101, the kinematic single chain The chain 101 includes a number of inner sections 102 and a number of outer sections 104, the inner sections 102 and the outer sections 104 are composed of two joint pieces 107, and two hinge base columns are arranged between the two joint pieces 107 of the inner section 102 103, there are two hinge base holes 105 penetrating between the two joint pieces 107 of the outer section 104, the hinge base column 103 at the lower end of the inner section 102 and the hinge base hole 105 at the upper end of the outer section 104 are movably installed, the The hinged base column 103 at the upper end of the inner section 102 and the hinged base hole 105 at the lower end of the other outer sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com