Oil measuring indicator for hydraulic pipeline and detecting method of indicator

A technology of hydraulic pipeline and measurement indication, which is applied in the direction of fluid pressure actuation system testing, fluid pressure actuation device, fluid pressure actuation system safety, etc. It can solve high maintenance cost, complicated oil circuit diagnosis, waste of manpower and material resources and other problems, to achieve the effect of convenient operation, saving manpower and material resources, and reducing water hammer vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

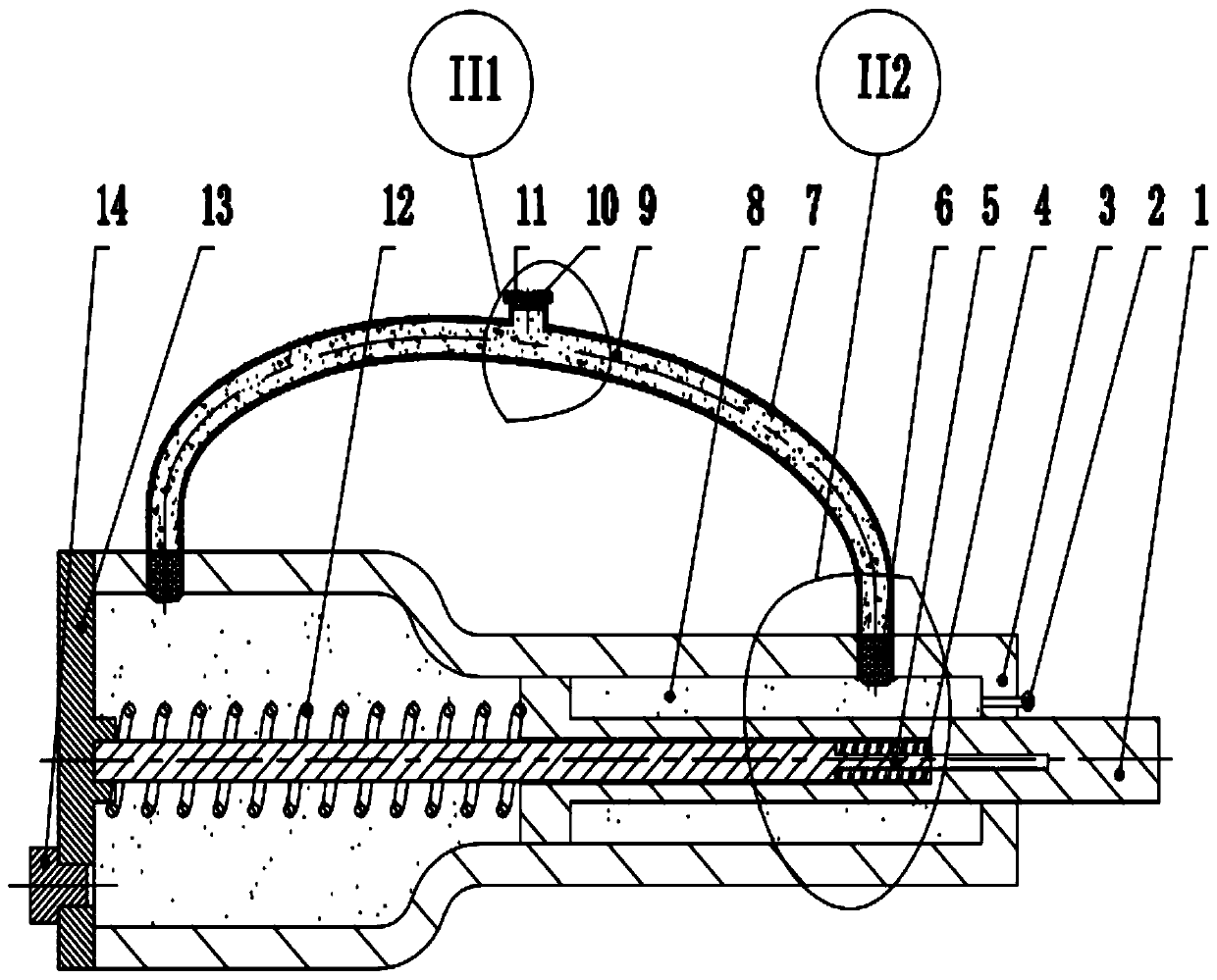

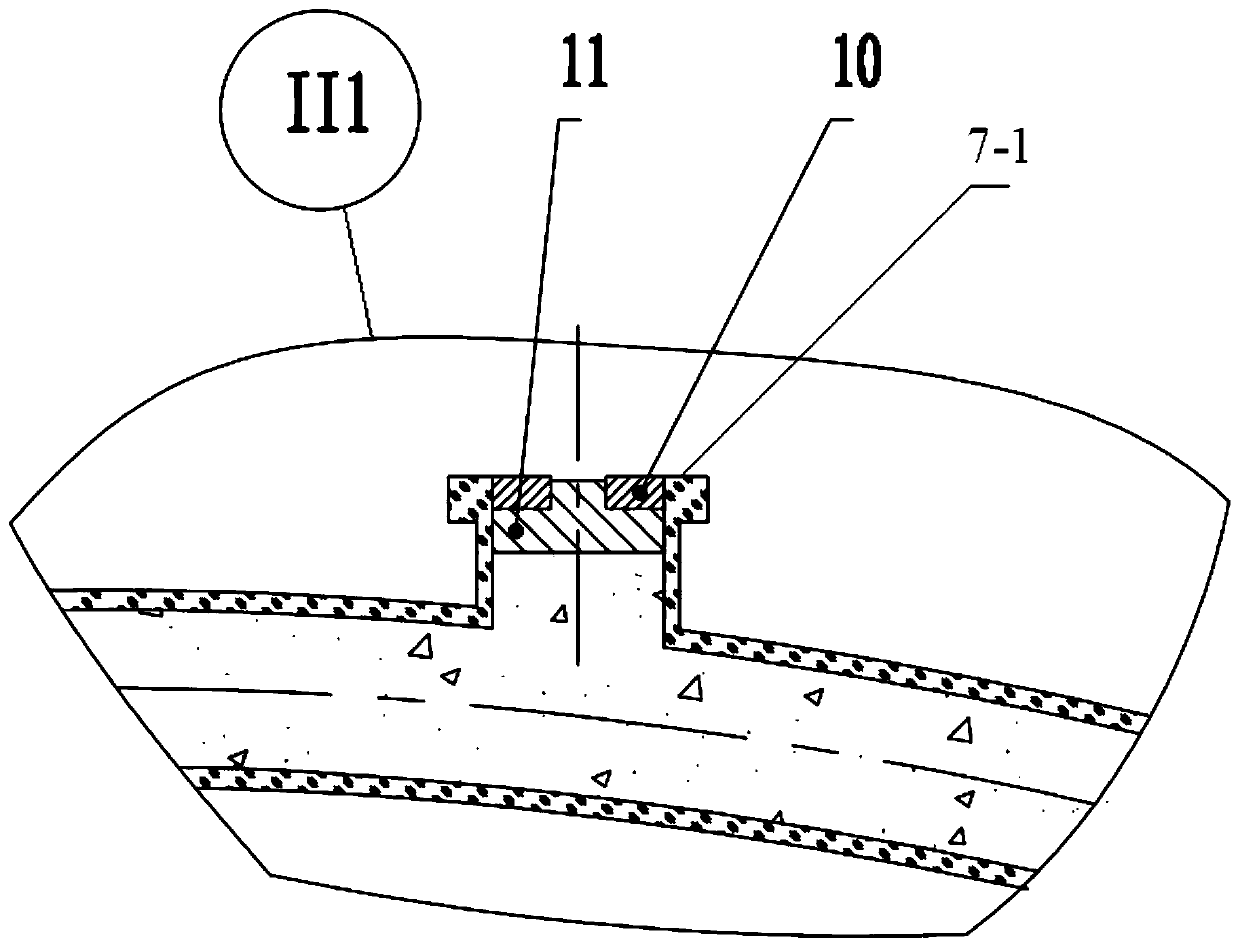

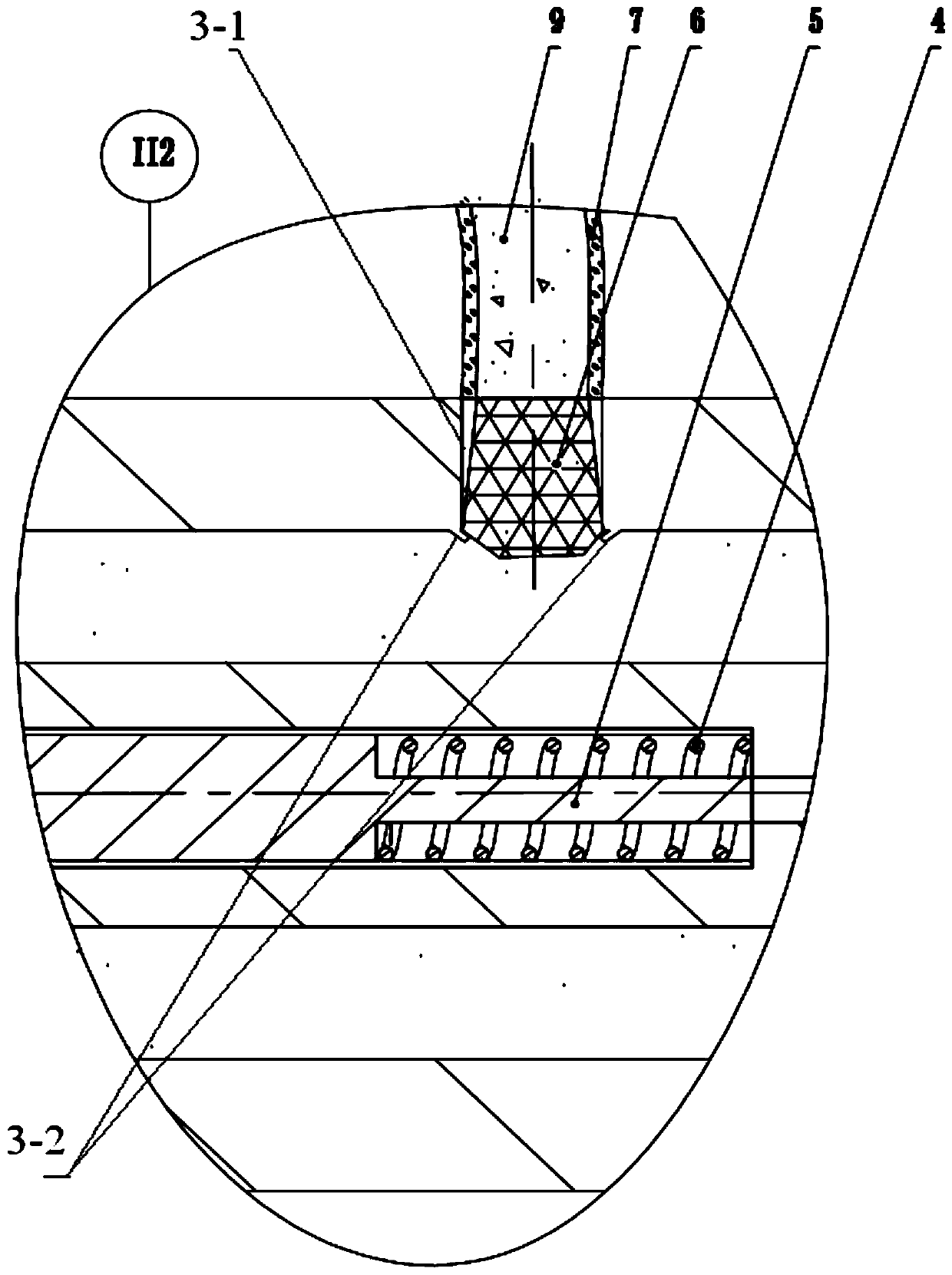

[0035] Such as figure 1 As shown, it includes T-shaped movable steel rod system piston 1, small chamber oil supply device 2, cylinder body 3, support spring 4, mobile steel rod system 5, isolation elastic deformation plug 6, indicating pipeline 7, hydraulic oil 8, Indicating medium 9, annular piezoelectric ceramics 10, pressure signal conversion piston 11, return spring 12, sealing cylinder head 13, liquid filling device 14; wherein: the large chamber end of cylinder body 3 is threadedly connected with sealing cylinder head 13 to realize cylinder body seal, the liquid filling device 14 is threadedly connected with the sealed cylinder head 13 to realize oil replenishment and liquid filling in the large chamber, and the small chamber oil replenishment device 2 and the small chamber end of the cylinder body 3 are threaded; the T-shaped mobile steel rod is connected to the piston 1 The inner end of the T-shape is slidingly connected with the inside of the cylinder body 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com