Tunnel blasting smoke emission device

A tunnel and buffer device technology, applied in the field of blasting engineering auxiliary devices, can solve problems such as affecting the health and safety of construction workers, affecting construction work efficiency, etc., and achieve the effects of shortening the ventilation and smoke dissipation time, ensuring health and safety, and quickly dispersing smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding and implementation of the present invention, the preferred embodiments of the present invention are selected for further description in conjunction with the accompanying drawings.

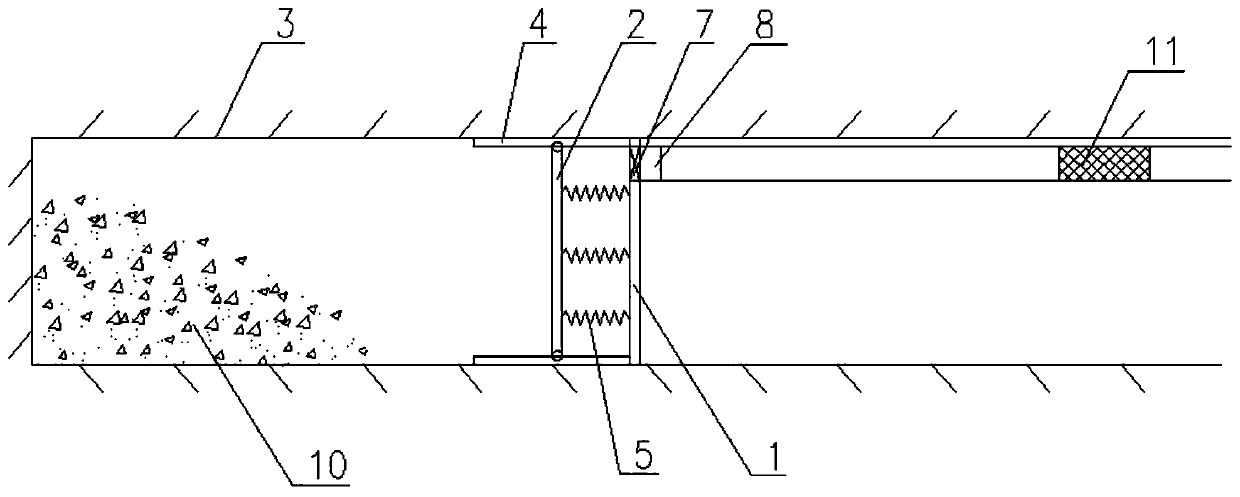

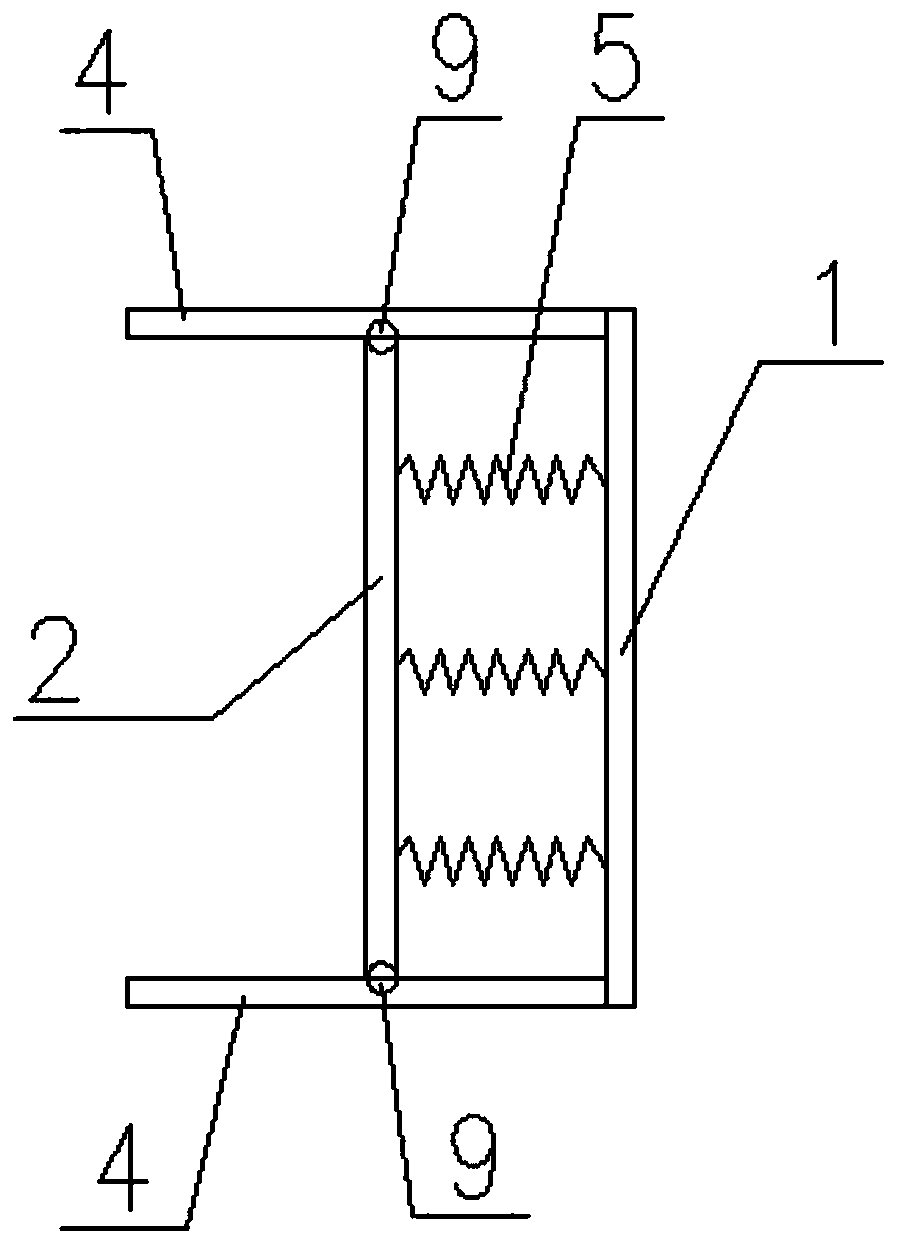

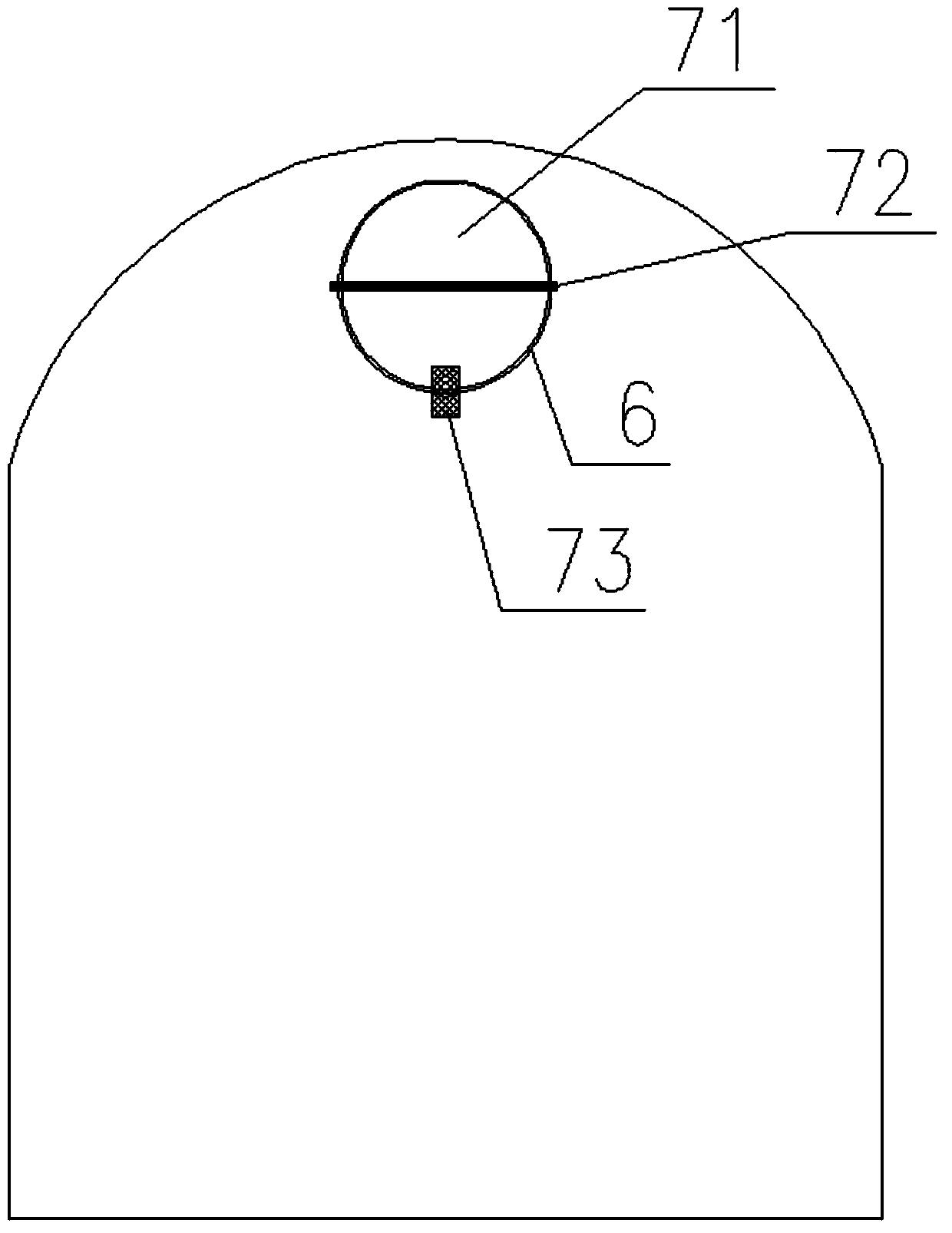

[0020] Such as Figure 1 to Figure 5 As shown, the present invention includes a fixed partition 1 and a movable partition 2, the shape specifications of the fixed partition 1 and the movable partition 2 are all compatible with the section shape specification of the tunnel 3, the fixed partition 1 and the movable partition 2 are Arranged on the same central axis, the movable partition 2 is equipped with a guide rail 4, so that the movable partition 2 can reciprocate along the guide rail 4, the length direction of the guide rail 4 is set along the thickness direction of the movable partition 2, the movable partition 2 and the fixed There is a buffer device 5 between the partitions 1, a smoke exhaust hole 6 is opened on the fixed partition 1, and a valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com