Micro-defect ultrasonic detection signal processing method considering surface roughness

A technology for surface roughness and ultrasonic testing, which is applied in the processing of detection response signals, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, and the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve the problems of difficult identification of fine defect signals , to improve the ability and reliability of ultrasonic detection of micro-defects under the influence of rough surfaces, improve the signal-to-noise ratio, and preserve the integrity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

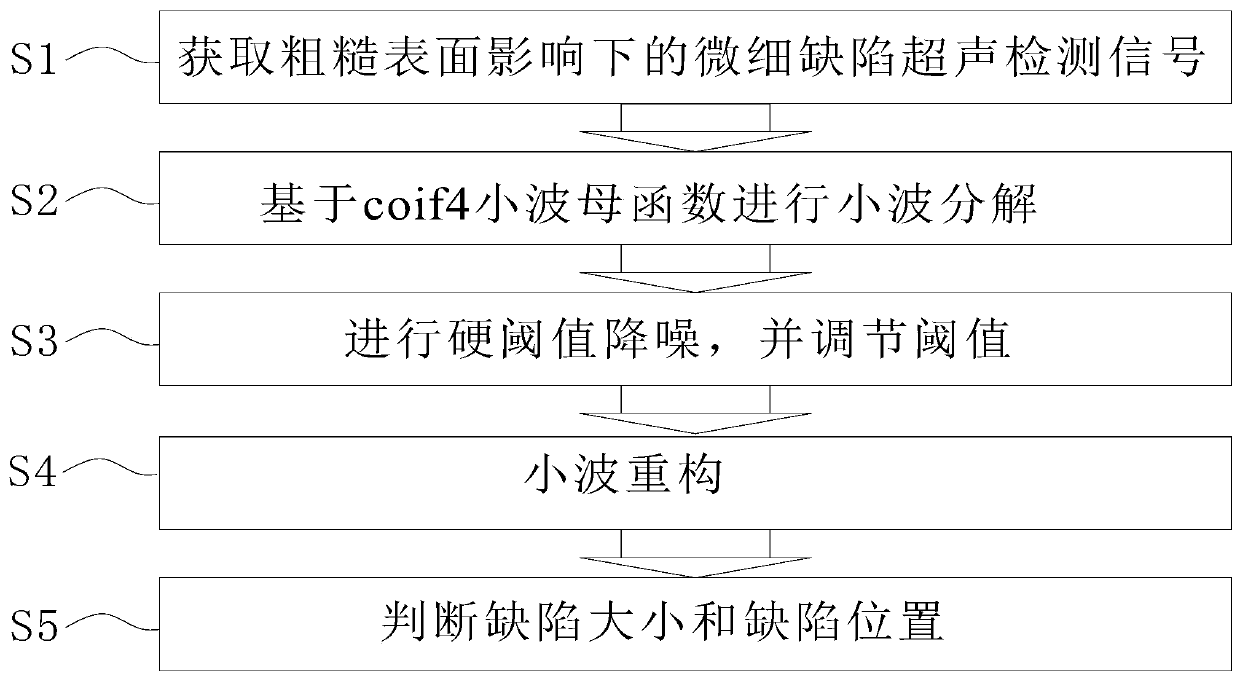

[0034] Such as figure 2 As shown, a micro-defect ultrasonic detection signal processing method considering surface roughness includes the following steps:

[0035] S1. Build a detection system to obtain ultrasonic detection signals of fine defects 12 under the influence of rough surface 11;

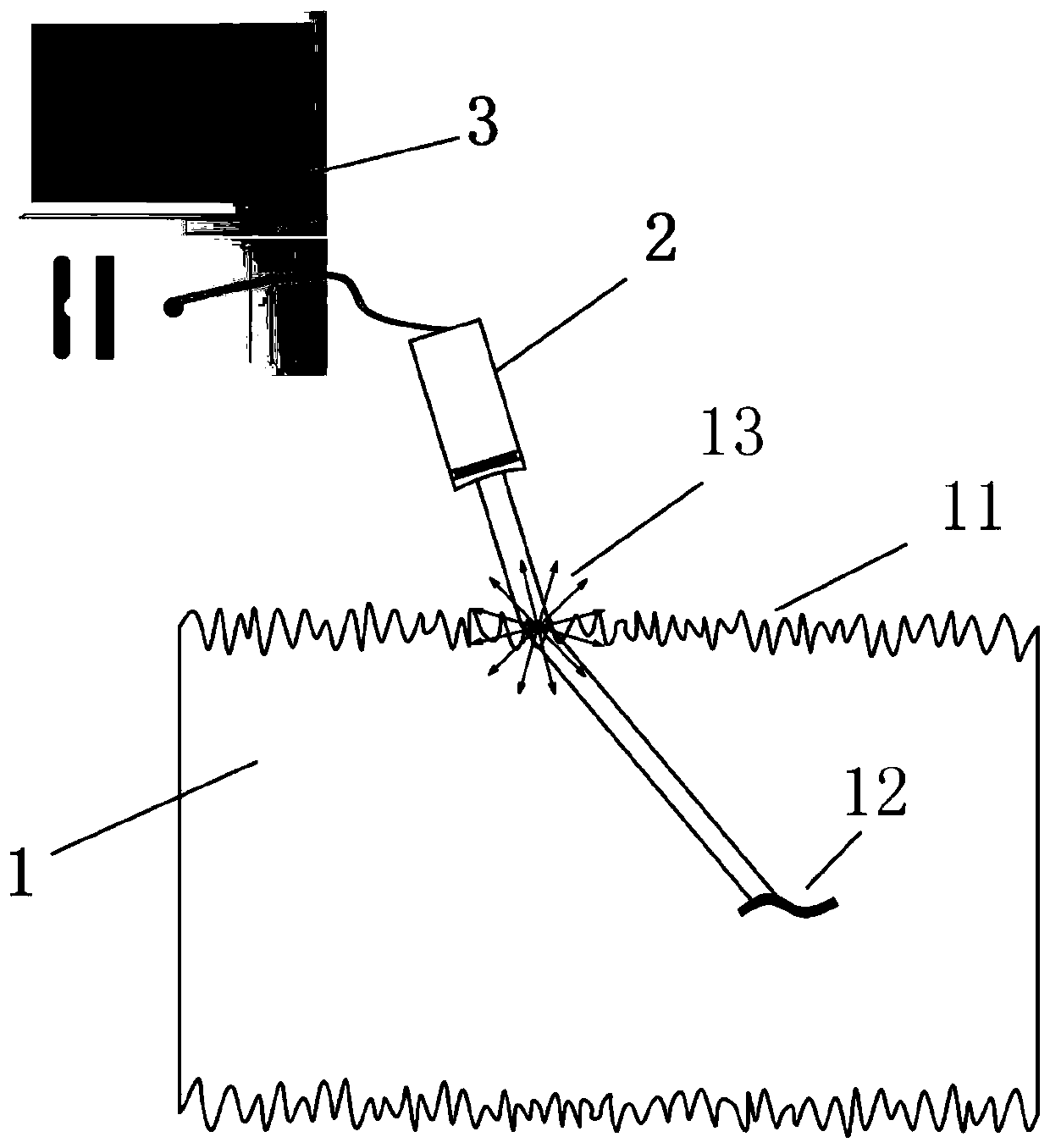

[0036] Such as figure 1 As shown, the detection system includes an ultrasonic probe 2 and an ultrasonic instrument 3. The ultrasonic probe 2 generates ultrasonic waves under the excitation of the ultrasonic instrument 3. The ultrasonic waves enter the workpiece 1 to be measured in the coupling medium, and longitudinal waves are generated in the workpiece 1 to be measured. Or shear wave for detection, when the sound beam encounters the fine defect 12 and then reflects, the reflected sound beam is received and displayed by the ultrasonic instrument 3 as an echo signal.

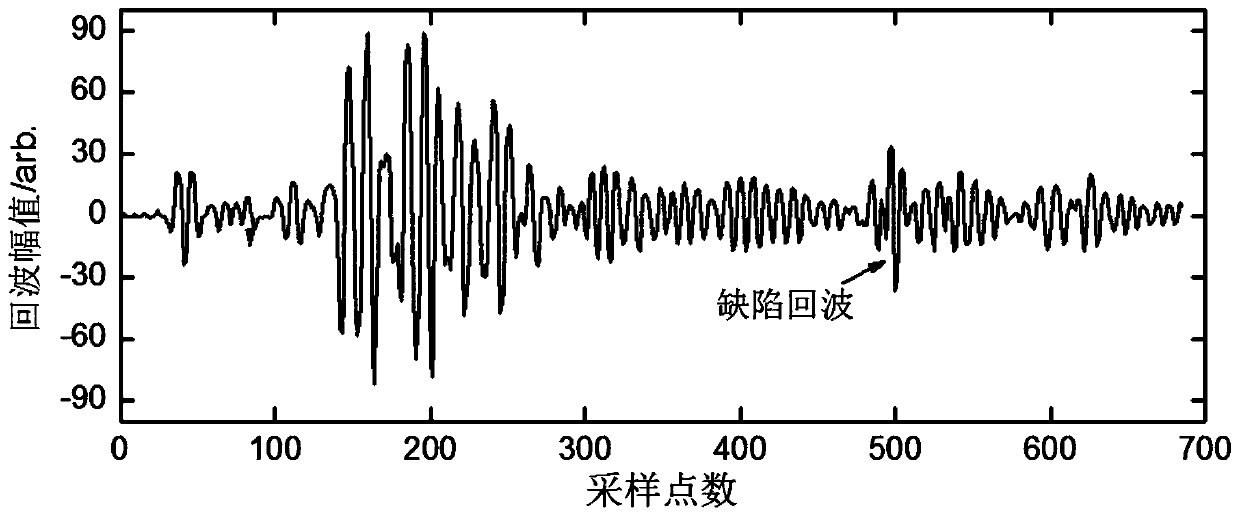

[0037] S2, using such as Figure 4 As shown, the wavelet mother function of coif4 in the Coiflet series of wavelets ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap