A large disc twisting machine

A wire stranding machine and disc type technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of cumbersome re-arrangement, lack of remedial measures, and the installation frame cannot be floated, and achieves the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

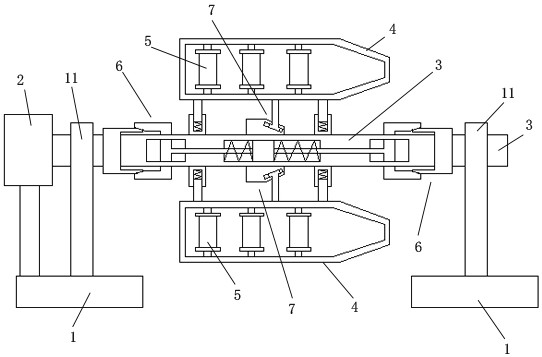

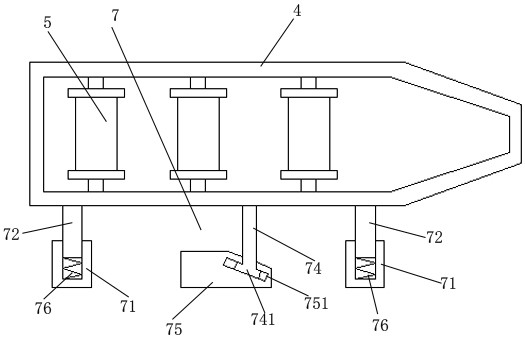

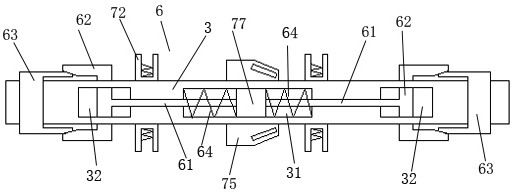

[0022] Such as Figures 1 to 7 As shown, a large-scale coil-type stranding machine includes a base 1 , a driving mechanism 2 , a rotating shaft 3 , a mounting frame 4 , a winding reel 5 , a connection assembly 7 , and an adjustment mechanism 6 . Both ends of the rotating shaft 3 are rotatably mounted on the base 1 through connecting columns 11; the driving mechanism 2 rotates and controls one end of the rotating shaft 3; the upper and lower sides of the rotating shaft 3 are respectively equipped with a mounting bracket 4; A plurality of reels 5 are installed in the installation frame 4; the installation frame 4 is installed on the outside of the rotating shaft 3 through the connection assembly 7; the connection assembly 7 includes a guide cylinder 71, a guide column 72, a moving block 77, a drive Block 75, moving bar 74; The side of described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com