Multistage straw fine crushing and dispersing field returning device

The technology of a crushing device and a throwing device is applied in the directions of cutters, agricultural machinery and implements, and applications, etc., and can solve the problems of difficulty in adjusting the width of the throwing, affecting the sowing operation of the next crop, and the unevenness of the throwing and covering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0143] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

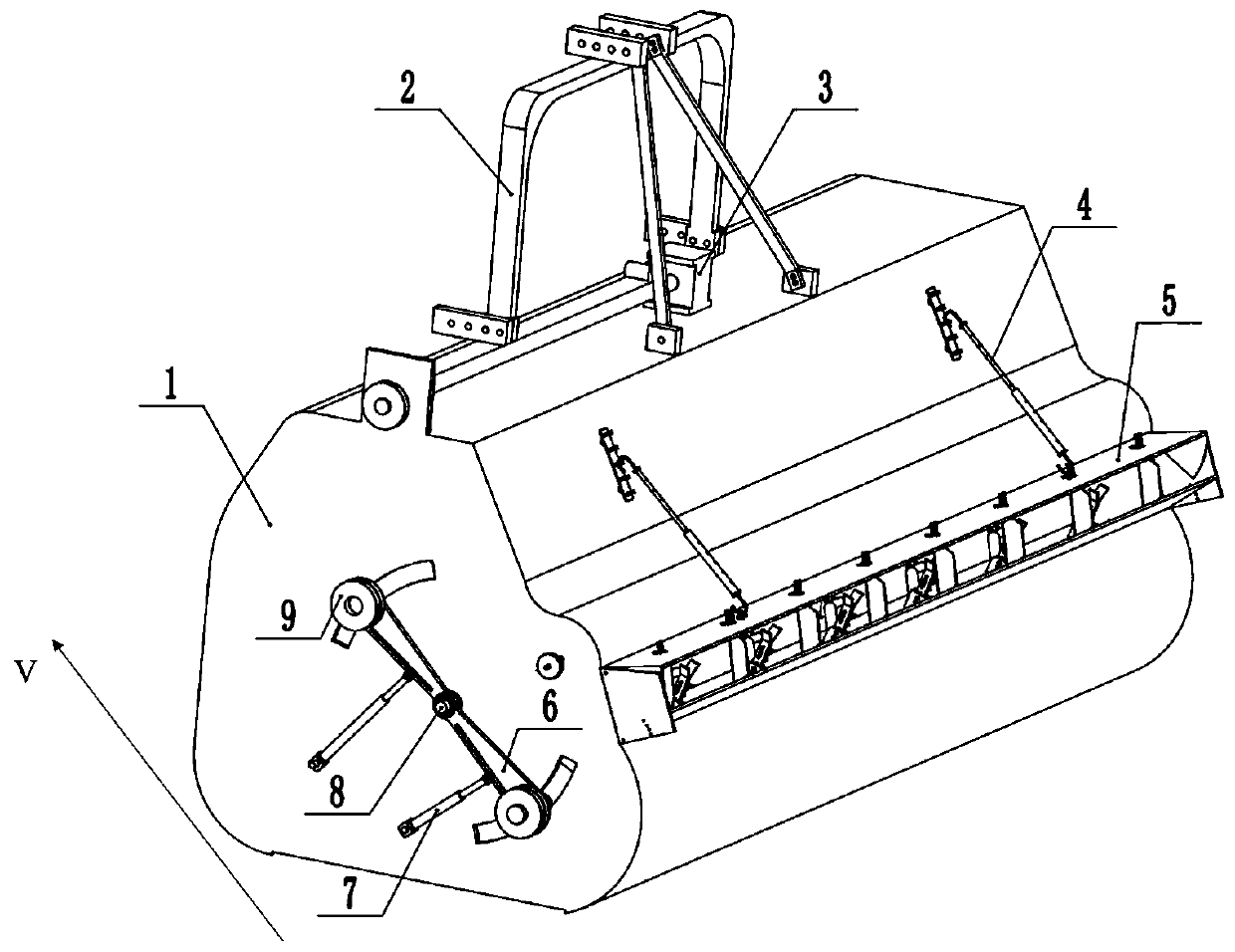

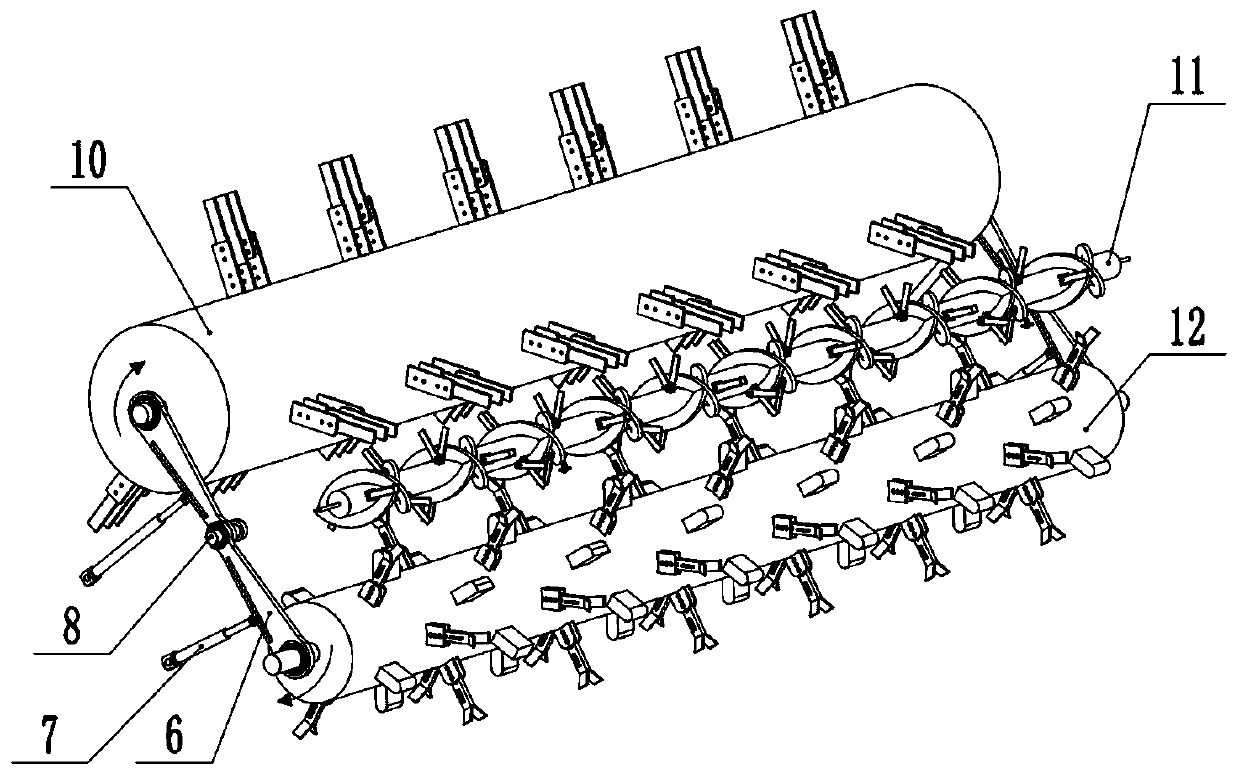

[0144] Such as Figure 1-Figure 3 As shown, a straw multi-stage fine crushing throwing and returning device of the present invention includes a casing 1, a suspension frame 2, a gearbox 3, a throwing adjustment device 4, a throwing device 5, a knife distance adjustment device 6, a hydraulic rod 7, Knife distance adjustment device support rod 8, transmission device 9, straight knife crushing device 10, throwing acceleration device 11 and picking up crushing device 12. Such as figure 1 As shown, the forward direction of the straw multi-stage fine crushing throwing and returning device is v.

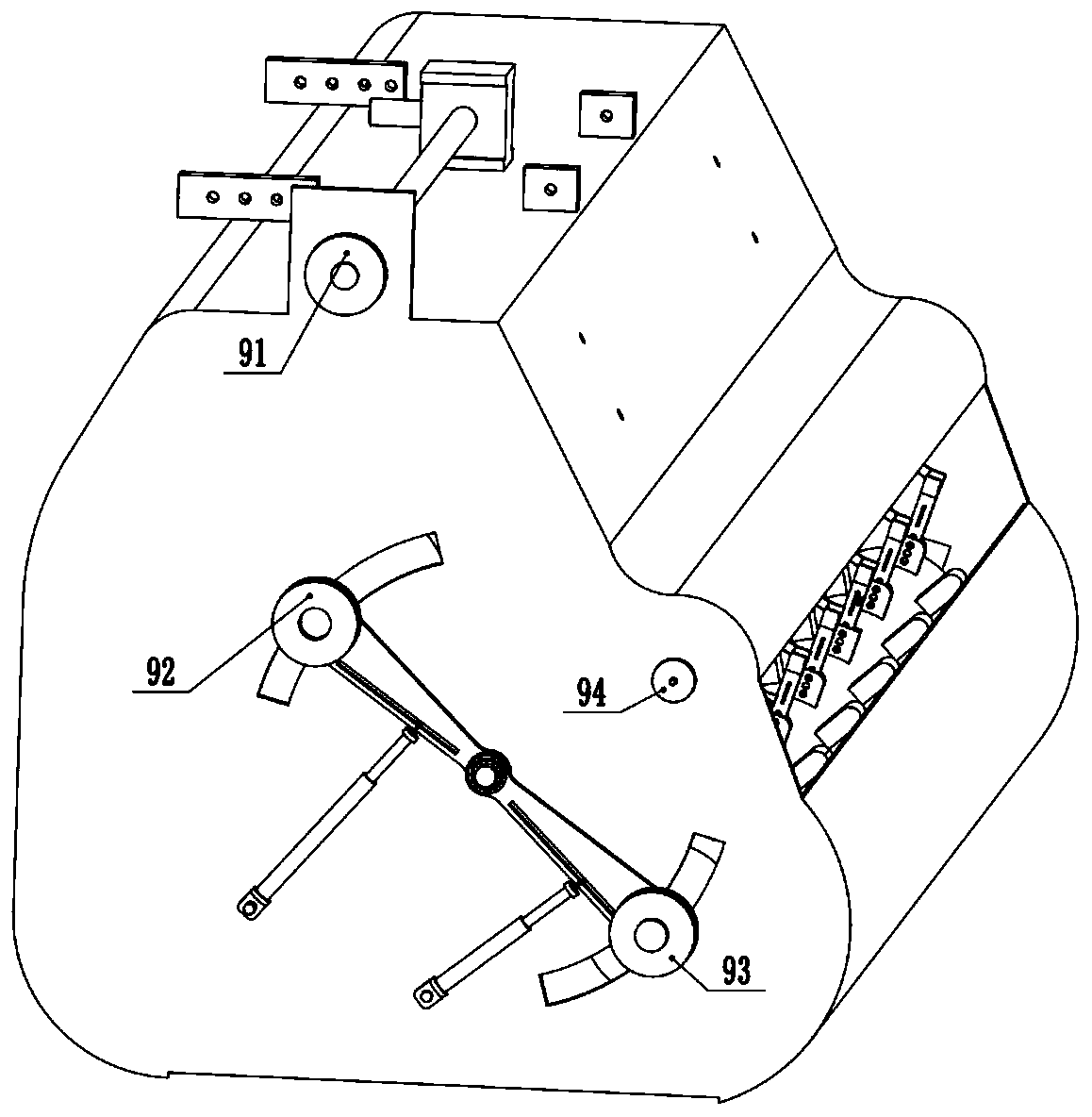

[0145] Such as Figure 4 As shown, the casing 1 includes a casing main body 113, an upper knife distance adjustment groove 1141, a lower knife distance adjustment groove 1142, a hydraulic rod support rod 115, a knife distance adjustment device support rod mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com