Control method of welding quality of erw pipe

A welding quality and quality technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of lack of quantitative and comparative representations, etc., and achieve the effects of clear direction, accurate quality judgment process, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

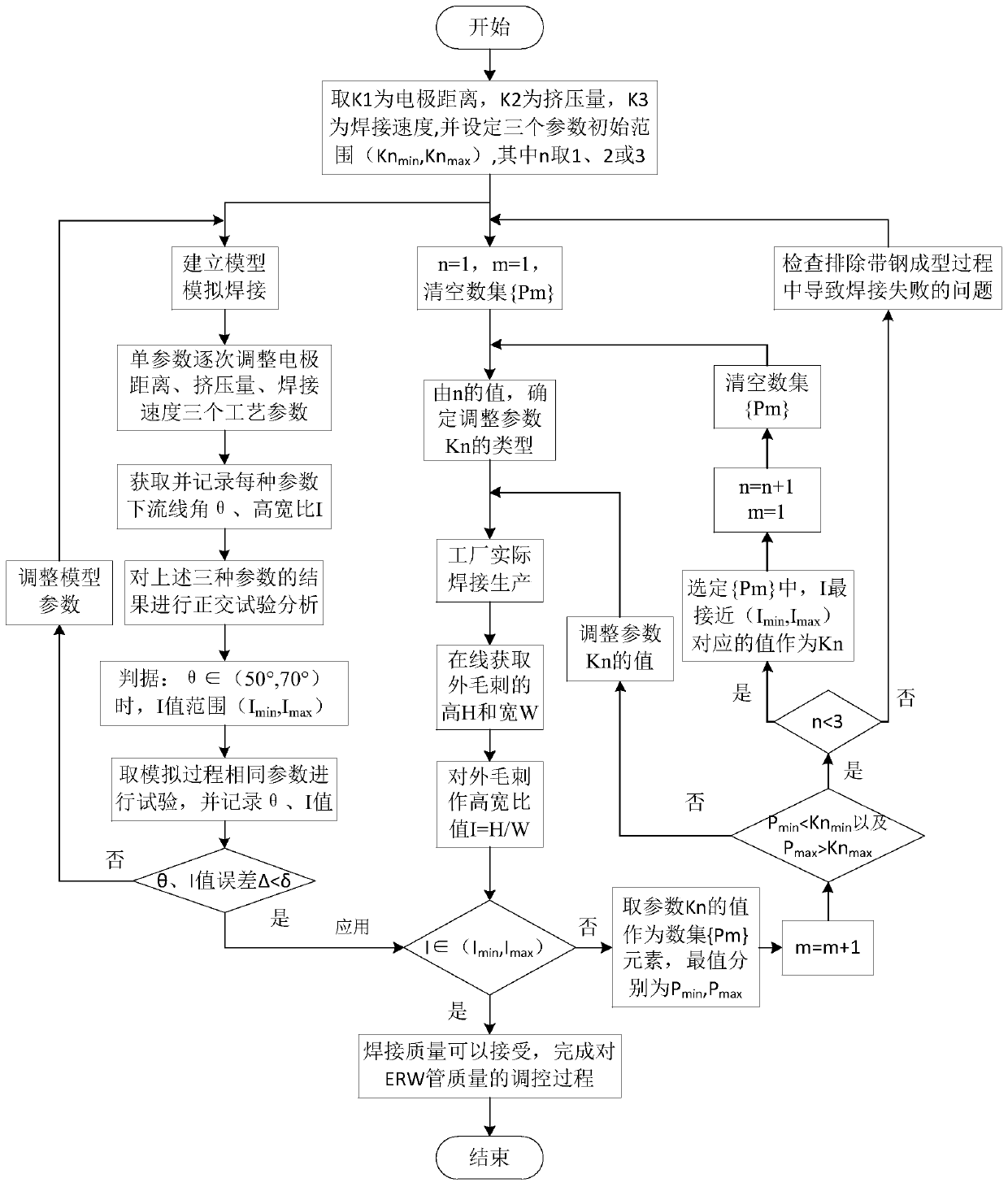

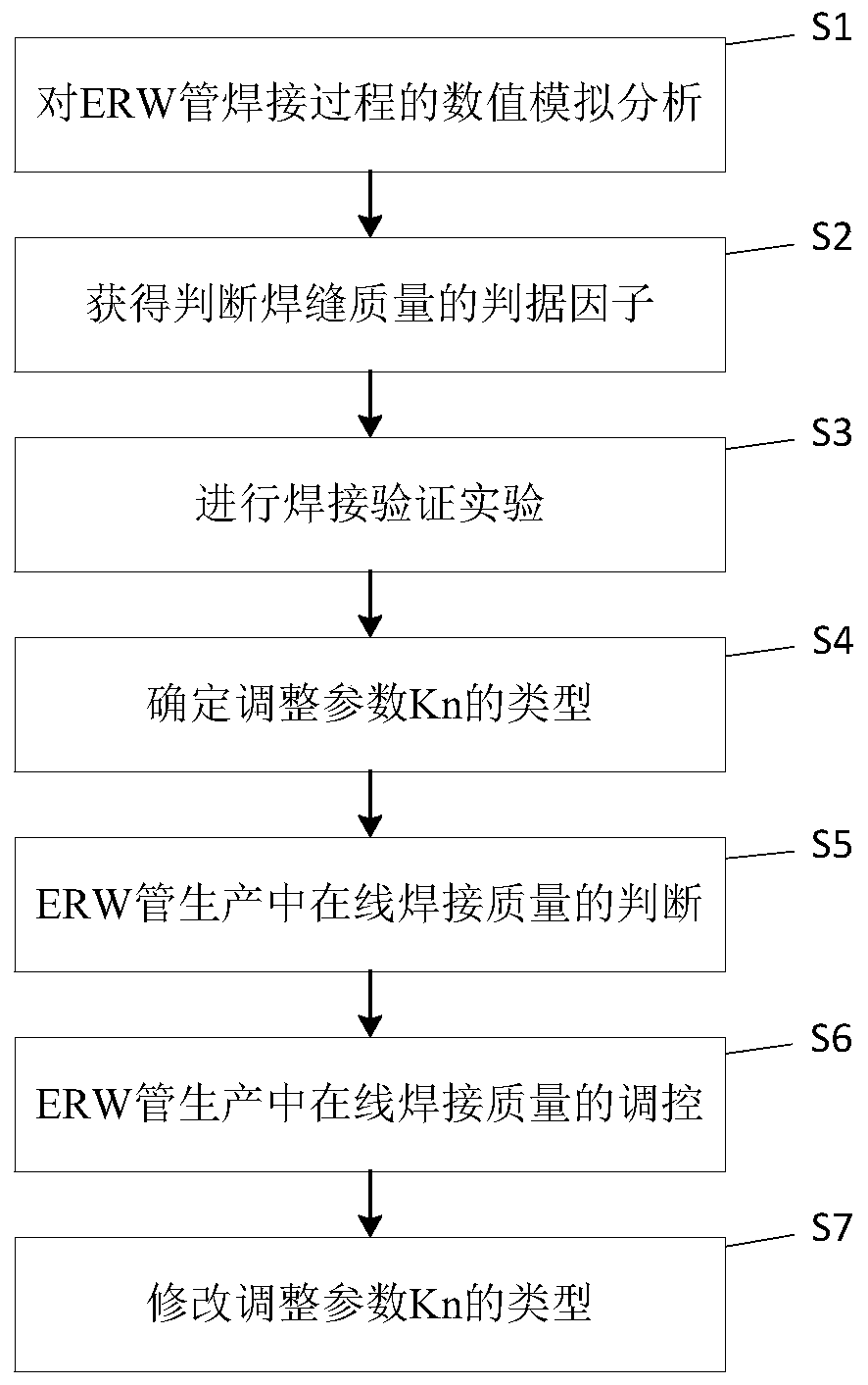

[0034] In order to better understand the technical solution of the present invention, the specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. And through the finite element simulation and experimental verification of the ERW pipe welding process, the distribution law of the aspect ratio I was observed to verify the feasibility of the method. The material is X80 steel and the specification is Φ355.6×12.7, and the numerical simulation is carried out. figure 1 Shown is the flow chart of the method for adjusting and controlling welding quality of ERW pipe of the present invention, which mainly includes the following steps:

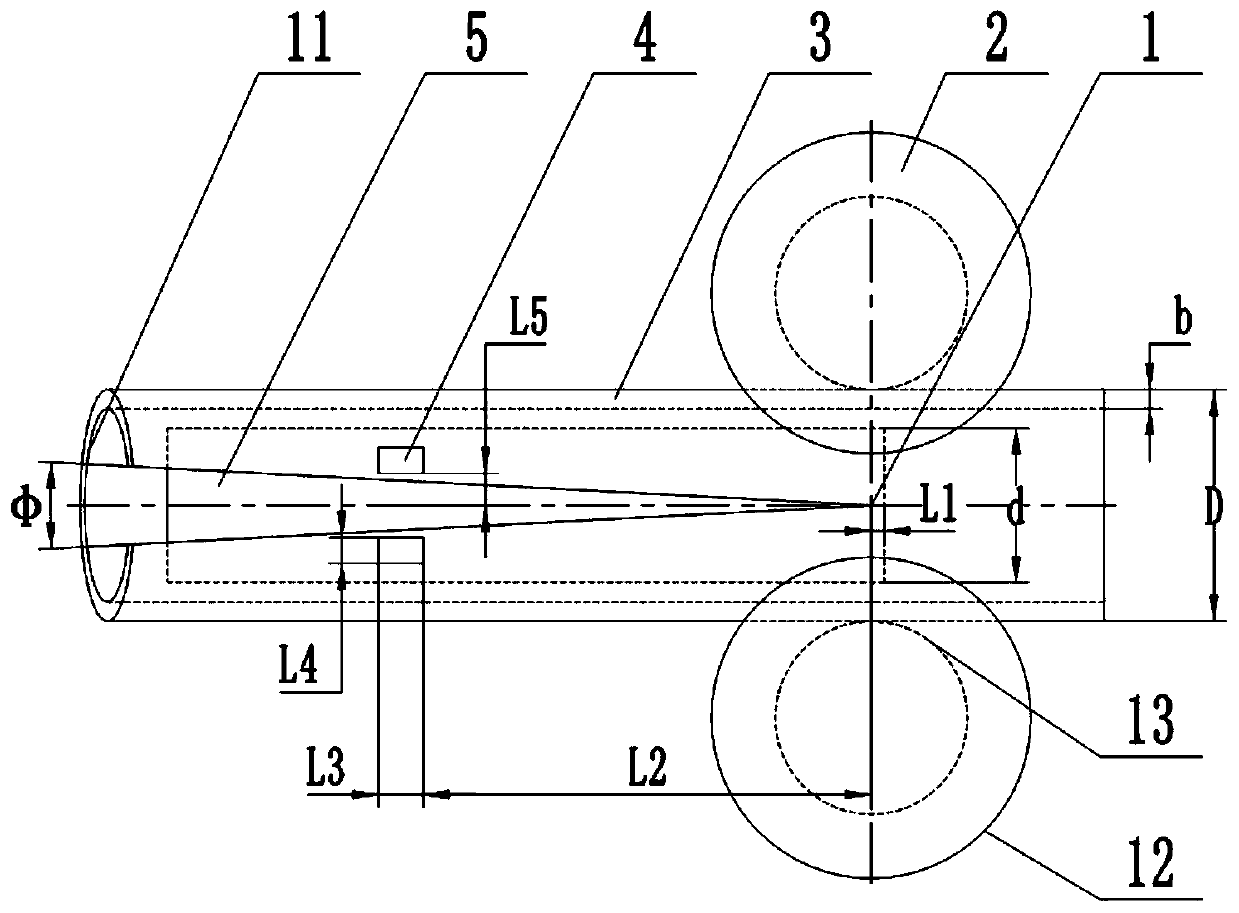

[0035] Step 1. Numerical simulation analysis: set the initial range of electrode distance K1, extrusion amount K2 and welding speed K3 respectively (Kn min , Kn max ), the set parameter n takes 1, 2 or 3, where the electrode distance refers to the horizontal dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com