A grooving machine for raglan tenon processing

A technology for grooving and sloping, which is applied in the field of raft tenon processing groovers, can solve the problems of increased workload and low grooving efficiency in raglano tenon processing, etc., so as to reduce workload, prevent physical fatigue, and improve grooving. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

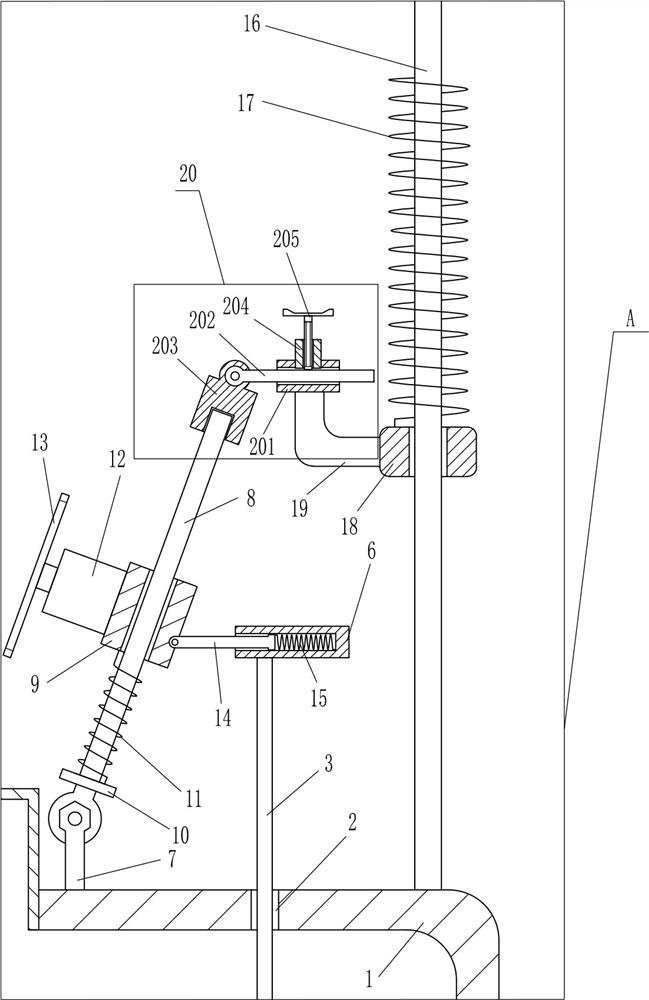

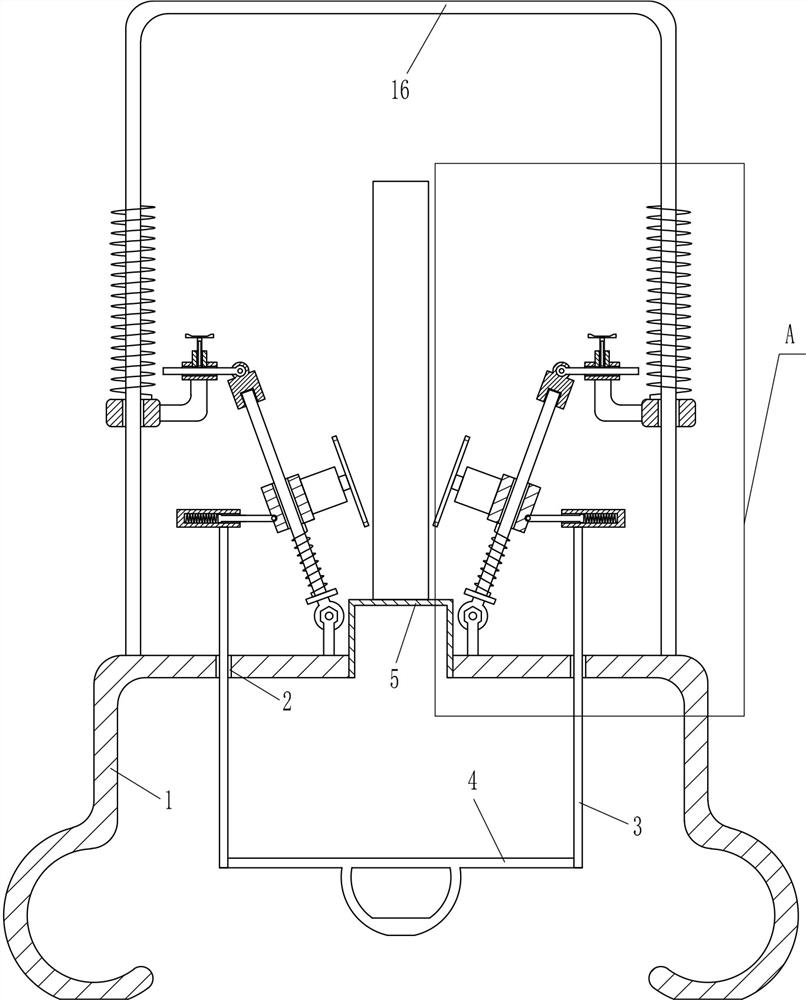

[0018] A grooving tool for raglan tenon processing, such as Figure 1-2 As shown, it includes a bracket 1, a guide rod 3, a slide tube, a first spring, a pedal 4, an n-shaped frame 5, a guide tube 6, a swing seat 7, a second slide rod 8, a first slide sleeve 9, a baffle plate 10, Second spring 11, one-way motor 12, first cutting wheel 13, the 3rd slide bar 14, the 3rd spring 15, n type bar 16, the 4th spring 17, the 2nd sliding sleeve 18, the first pole 19 and adjustment Fixture 20, the left and right sides of the top of the bracket 1 are provided with guide holes 2, the guide holes 2 are slidingly provided with guide rods 3, pedals 4 are installed between the lower parts of the inner sides of the left and right guide rods 3, and the guide rods 3 Connected with the pedal 4 by welding, the n-shaped frame 5 is embedded in the middle of the top of the bracket 1, the top of the guide rod 3 is fixed with a conduit 6, and the left and right sides of the top of the bracket 1 are prov...

Embodiment 2

[0020] A grooving tool for raglan tenon processing, such as Figure 1-2As shown, it includes a bracket 1, a guide rod 3, a slide tube, a first spring, a pedal 4, an n-shaped frame 5, a guide tube 6, a swing seat 7, a second slide rod 8, a first slide sleeve 9, a baffle plate 10, Second spring 11, one-way motor 12, first cutting wheel 13, the 3rd slide bar 14, the 3rd spring 15, n type bar 16, the 4th spring 17, the 2nd sliding sleeve 18, the first pole 19 and adjustment Fixing device 20, the left and right sides of the top of the support 1 are provided with guide holes 2, and guide rods 3 are slidingly provided in the guide holes 2, and pedals 4 are installed between the lower parts of the inner sides of the left and right guide rods 3, and n-shaped frame 5 is embedded in the middle of the top of the bracket 1, the top of the guide rod 3 is fixed with a conduit 6, the left and right sides of the top of the bracket 1 are provided with swing seats 7, and the left and right swing...

Embodiment 3

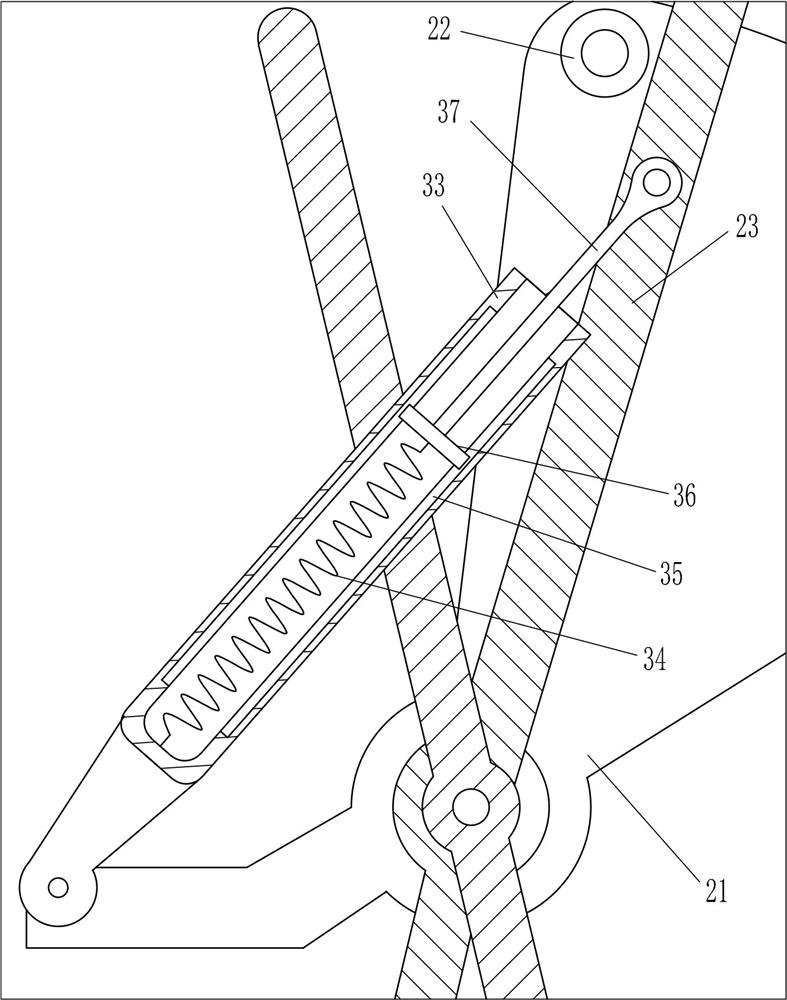

[0023] A grooving tool for raglan tenon processing, such as Figure 1-3 As shown, it includes a bracket 1, a guide rod 3, a slide tube, a first spring, a pedal 4, an n-shaped frame 5, a guide tube 6, a swing seat 7, a second slide rod 8, a first slide sleeve 9, a baffle plate 10, Second spring 11, one-way motor 12, first cutting wheel 13, the 3rd slide bar 14, the 3rd spring 15, n type bar 16, the 4th spring 17, the 2nd sliding sleeve 18, the first pole 19 and adjustment Fixing device 20, the left and right sides of the top of the support 1 are provided with guide holes 2, and guide rods 3 are slidingly provided in the guide holes 2, and pedals 4 are installed between the lower parts of the inner sides of the left and right guide rods 3, and n-shaped frame 5 is embedded in the middle of the top of the bracket 1, the top of the guide rod 3 is fixed with a conduit 6, the left and right sides of the top of the bracket 1 are provided with swing seats 7, and the left and right swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com