Polishing wire drawing device

A polishing wheel and spindle technology, which is applied in the field of polishing machines, can solve problems such as low efficiency, inconvenience, and time-wasting, and achieve the effect of reducing the time for changing abrasive materials and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

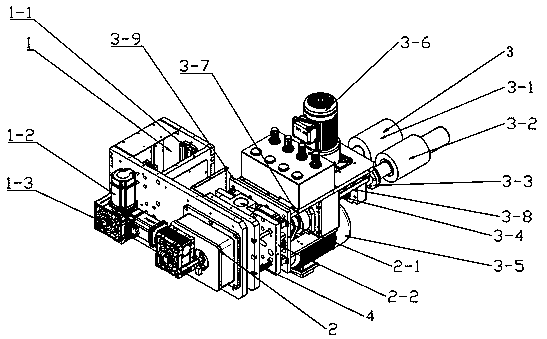

[0014] Embodiment 1: As shown in the figure, a polishing wire drawing device includes a main shaft, a lifting mechanism 1, a rotating mechanism 2, and a polishing mechanism 3. The feature is that the lifting mechanism 1 consists of a guide rod, a slider 1-1, and a motor. 1-2 and a worm gear reducer 1-3, the rotating mechanism 2 includes an angle adjustment shaft 2-1, a guide rail bottom plate 2-2, and the grinding mechanism 3 includes a first grinding head 3-1 and a second grinding head 3-2, the upper motor 3-6, the lower motor 3-5, the second grinding head 3-2 is equipped with an extended flying wing wheel, the first 3-1, second 3-2 grinding heads are connected The flange 3-3 is connected with the polishing wheel spindle 3-4, and the lower motor 3-5 and the spline bearing 3-7 are driven by a belt. Vibration guide rail bottom plate 3-8 is installed between the polishing wheel spindle 3-4 and the upper motor 3-6, and dust-proof plates are installed around the polishing wire draw...

Embodiment 2

[0015] The second embodiment: other structures are the same as the first embodiment, the difference is that a motor is added to control the rotation of the two magic heads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com