Swing type stepless rack locking device

A technology for locking devices and racks, which is applied in the field of swing-type stepless rack locking devices, and can solve problems such as damage to gears on the locking end face of fixed-length baffles, inability to achieve reliable locking, and inability to achieve stepless locking. , to achieve the effect of no need for manual intervention, simple structure, and good stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

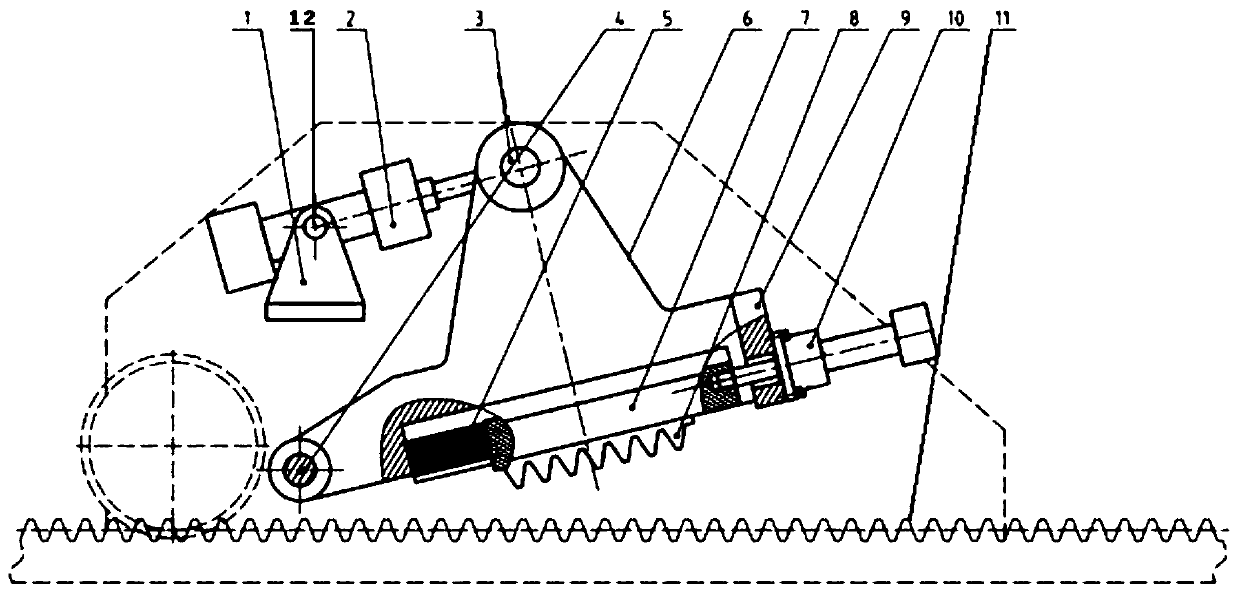

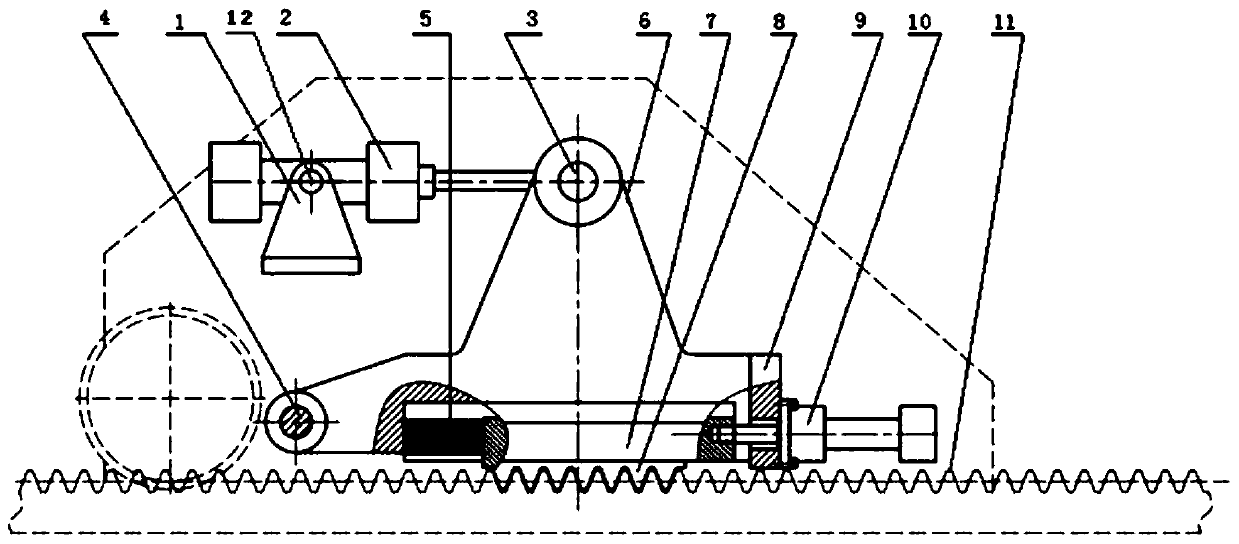

[0013] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are further described:

[0014] see figure 1 , figure 2 A swing-type stepless rack locking device is composed of two parts, a moving part and a fixed part, wherein the moving part includes an oil cylinder base 1, and the oil cylinder base 1 is connected to the middle section of the swing oil cylinder 2 through a hinge shaft 12, and the swing oil cylinder 2 The piston end of the swing arm 6 is connected to the top end of the swing arm 6 through the first pin shaft 3, one end of the bottom of the swing arm 6 is hinged with the second pin shaft 4, and the other end of the bottom of the swing arm 6 is connected with a stopper through an oil cylinder mounting seat 9. Oil cylinder 10; the bottom of the swing arm 6 is provided with a slideway 7, one end of the spring 5 is connected to the end of the slideway 7 close to the second pin shaft 4, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com