Mold and mold body with lengths of mold pins adjustable

An adjustable, mold-body technology, applied in the field of mold production, can solve the problems of mold design, high manufacturing cost, poor production flexibility, etc., and achieve the effect of satisfying flexible production and reducing design and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] As mentioned in the background technology section, most of the nails of the existing molds are fixed-length designs. Once different drilling depths are required, for example, when the thickness of the latex products produced changes, the depth of the vent holes of the latex products will also be different. At this time, it is necessary to redesign and produce a new mold, resulting in an increase in the design and manufacturing costs of the mold.

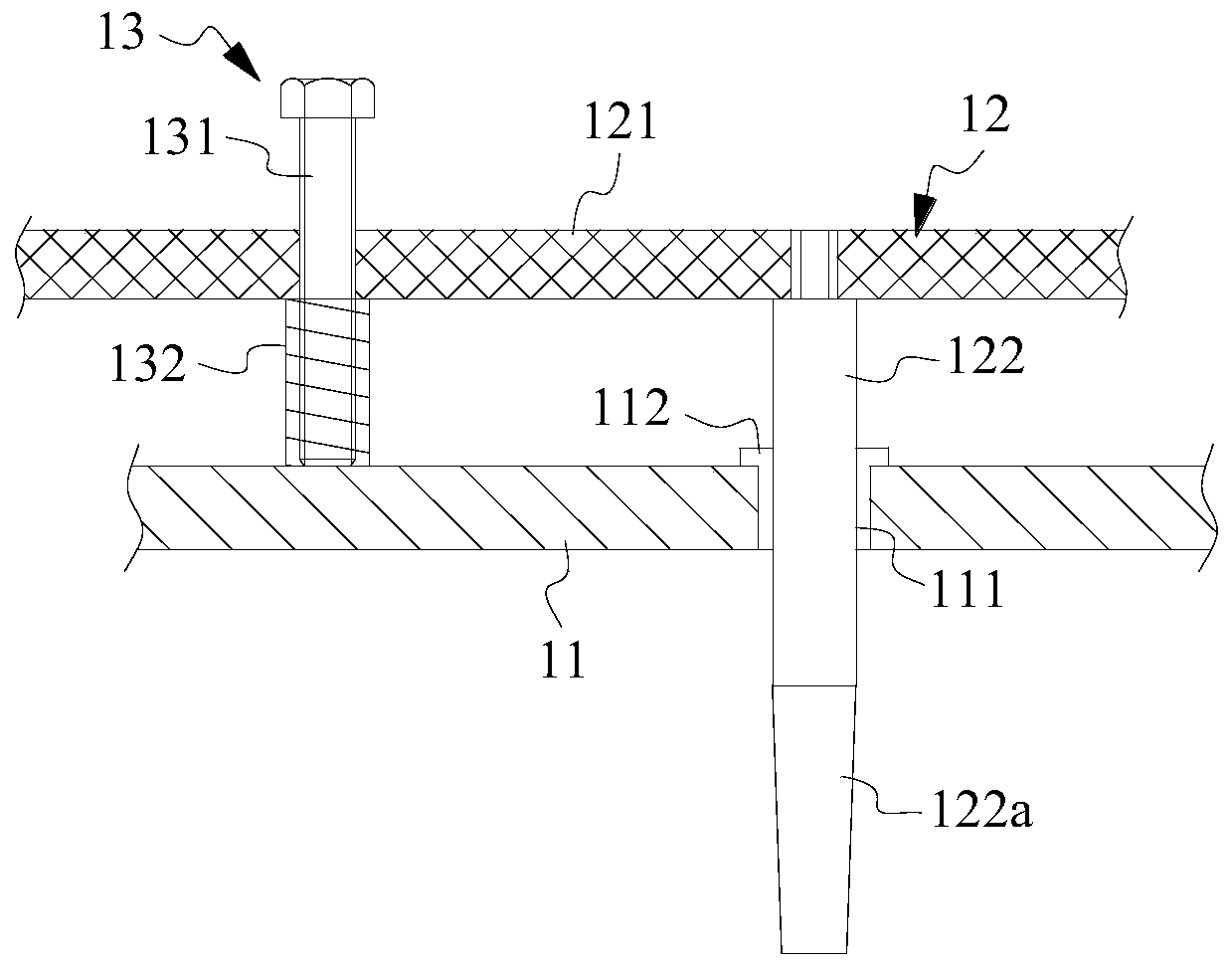

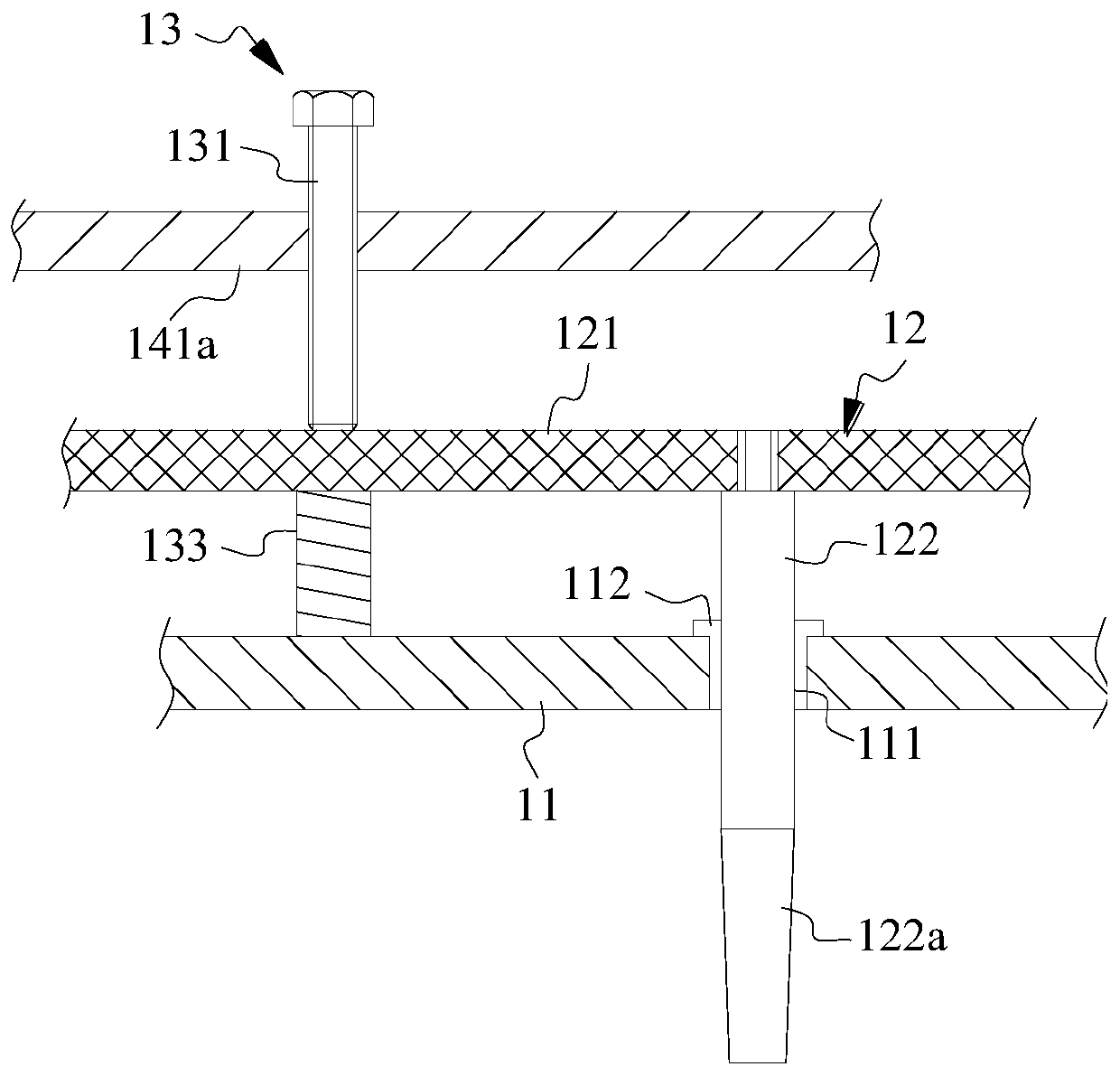

[0040] For this reason, the present invention provides a mold body with adjustable nail length, including an orifice plate 11 and a nail plate 12, the nail plate 12 includes a plate body 121 and some form nails 122 installed on the plate body 121, the orifice plate 11 is provided with Several nail holes 111, mold nails 122 are the same as the number of nail holes 111, and each mold nail 122 can be inserted into each nail hole 111 in a one-to-one correspondence; also includes a first adjusting part 13, the first adjusting part 1...

Embodiment 2

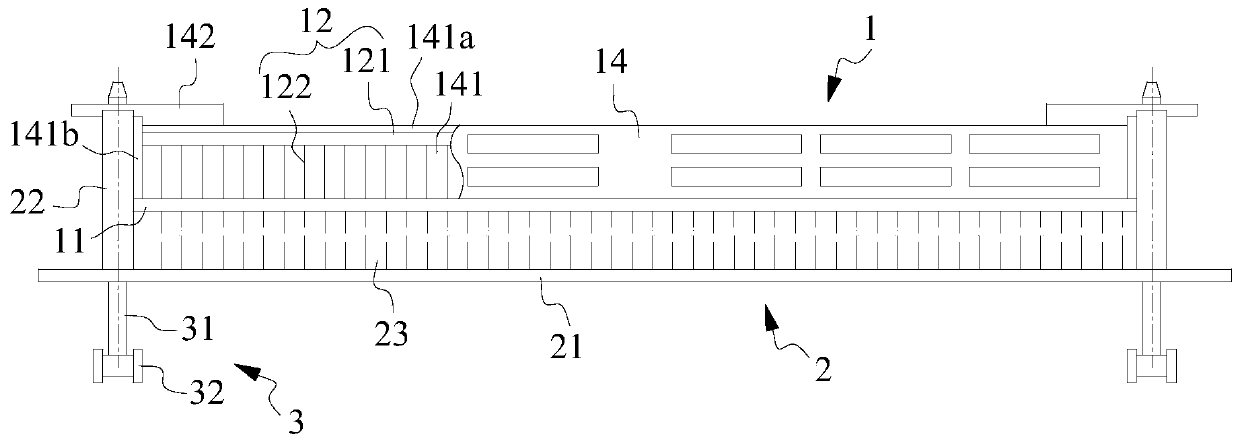

[0062] Such as figure 1 As shown, based on the mold body in Embodiment 1, the present invention also provides a mold, including a butt joint first mold body 1 and a second mold body 2, at least one of the first mold body 1 and the second mold body 2 One can be the mold body in which the length of the mold nail 122 in the first embodiment can be adjusted.

[0063] Since the mold body in the first embodiment already has the above-mentioned technical effects, the mold with the mold body should also have similar technical effects, which will not be repeated here.

[0064] Taking a specific latex mattress mold as an example, combined with figure 1 , Figure 4 , the first mold body 1 can be an upper mold, which can adopt the mold body with adjustable length of mold nails 122 in the first embodiment, the second mold body 2 can be a lower mold, and the lower mold can include a bottom plate 21 and a side plate 22. A mold body 1 can be installed in the second mold body 2 to form a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com