A PVC pipe processing anti-clogging extrusion production equipment

A production equipment, anti-clogging technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of not reaching the pipe for the rubber block, slipping, compression ratio and gap that do not meet the requirements of the traction machine rubber block, etc., to improve the clamping force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

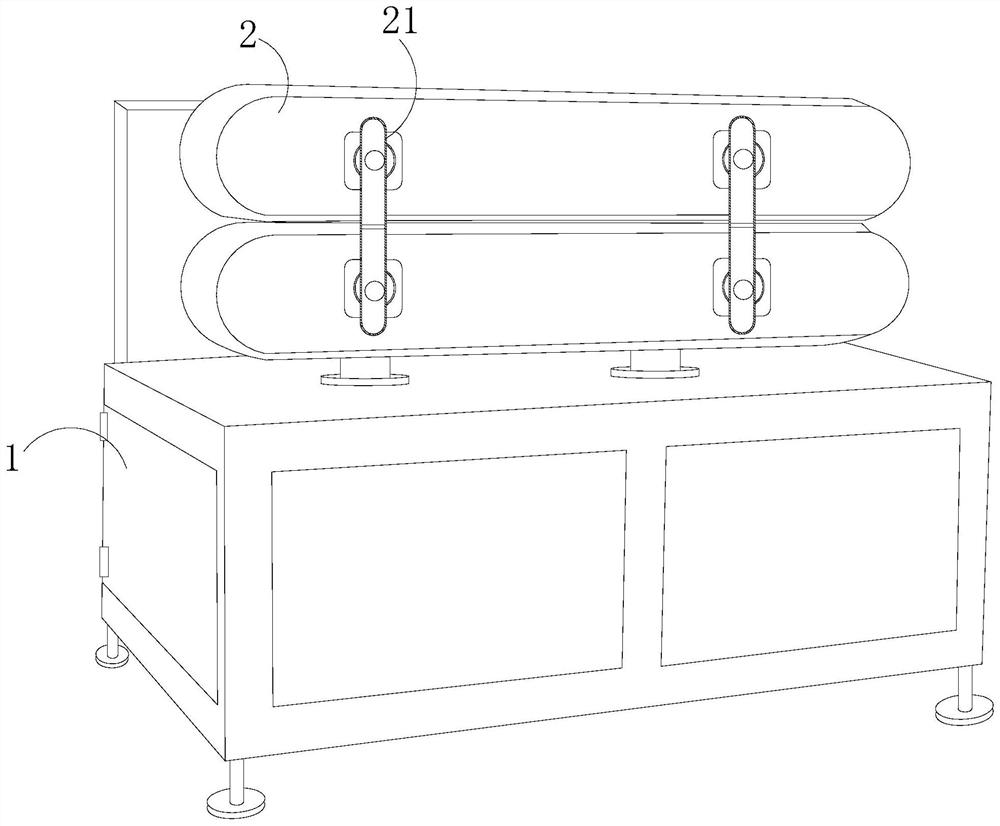

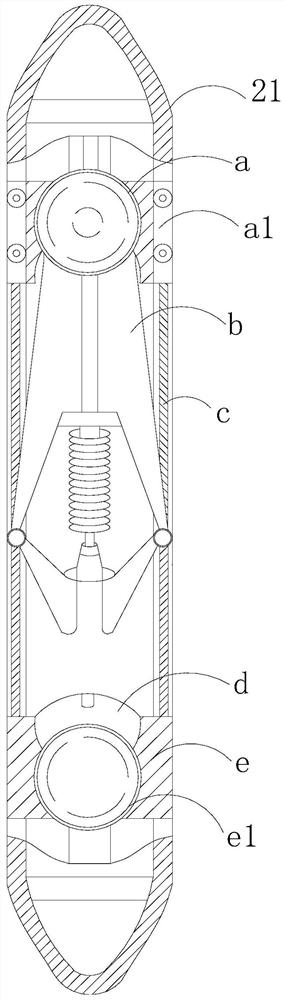

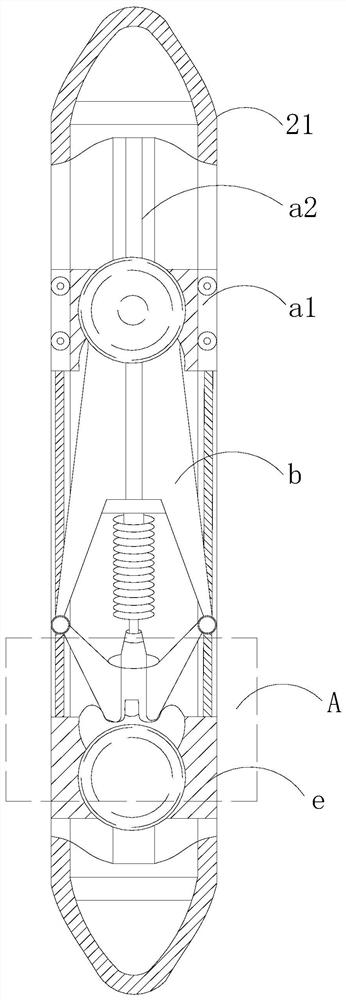

[0028] Such as Figure 1-Figure 6 As shown, the present invention provides a PVC pipe processing anti-blocking extrusion production equipment, its structure includes a chassis 1, traction crawler 2, rubber block seat 3, rubber block 4, the traction crawler 2 is provided with two and installed through the shell The crawler joints 21 are connected up and down, the chassis 1 is mechanically connected with traction tracks 2, the rubber block 4 is fixed on the traction track 2 through the rubber block seat 3, and the track joints 21 include a sliding part a , triangular seat b, screw c, sounder d, fixing part e, described sliding part a fixes the described traction crawler 2 that is positioned at the upper end, and fixing part e is fixed on the traction crawler 2 that is positioned at the lower end, and described sounder d sets On the fixing part e, the triangular seat b is arranged between the sliding part a and the fixing part e, and both sides of the triangular seat b are movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com