Hinge type anti-explosion container power assisting mechanism

A power-assisting mechanism and hinge-type technology, applied in the field of hinged anti-explosion container power-assisting mechanism, can solve the problems of large lateral occupation volume, unfavorable transportation operation, heavy upper cover weight, etc., and achieve small opening and closing occupation volume, high safety, Effort-saving effect of opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

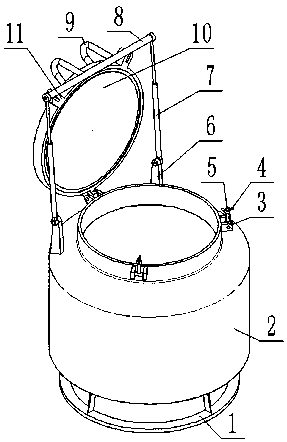

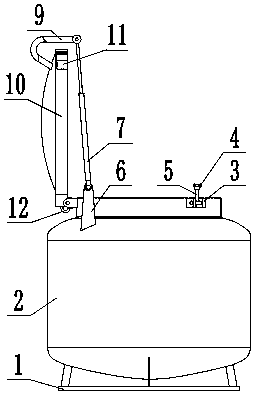

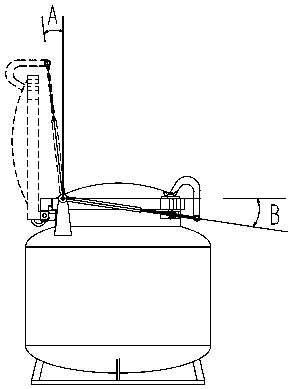

[0019] Combine below Figure 1-2 Describe this embodiment mode, the present invention relates to a kind of hinge type anti-explosion container booster mechanism, comprise container can 2 and sealing cover 10; The connecting seat 6 provided is formed to be connected in rotation, and the other end of the elastic member 7 forms a rotating connection with the handle 8 arranged on the connecting member 9; the length of the handle 8 is greater than the diameter of the opening of the container tank 2, which is convenient for installing the elastic member 7; 7 is preferably a gas spring, and the sealing cover 10 is also provided with a connecting part 9 and a limit block 12; The locking part is composed of bolts, pin shaft 5, butterfly nut 4, pin shaft seat 3 and U-shaped fastener 11, the bolt is fixed on the pin shaft 5, and the pin shaft seat 3 matched with the pin shaft 5 is fixed on the On the outer cylinder of the container tank 2, the U-shaped fastener 11 matched with the bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com