An automatic control system and method for anti-derailment of front stacker containers

A control method and container technology, applied in the field of reach stackers, can solve problems such as derailment of flatbed trucks and difficulties in uncoupling of F-TR locks, and achieve the effect of reducing the probability of derailment accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

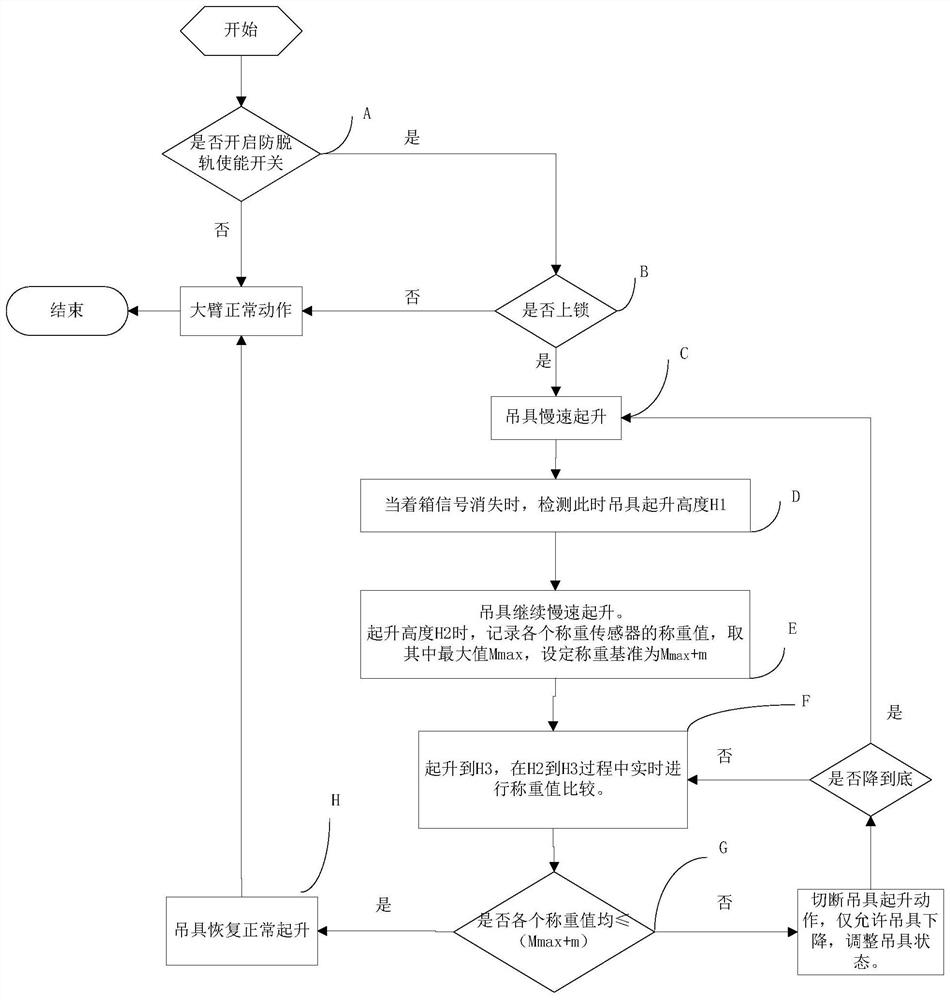

[0038] like image 3 As shown, a front stacker container anti-derailment automatic control method comprises the following steps:

[0039] A. After closing the anti-derailment enabling switch, the locking sensor installed on the spreader is used to detect whether the spreader and the container are locked; when the spreader and the container are locked, the locking sensor will send a locking signal sent to the vehicle controller;

[0040] B. When the spreader and the container are not locked, the boom of the reach stacker moves at normal speed;

[0041] C. When the spreader and the container are locked, a proportional solenoid valve is installed at the oil inlet end of the lifting cylinder. The power supply end of the proportional solenoid valve is connected to the output end of the vehicle controller, and the vehicle controller receives After the sensor signal is locked, a small current is output to control the opening of the proportional solenoid valve to become smaller, the...

Embodiment 2

[0054] An automatic control method for anti-derailment of a front stacker container, comprising the following steps:

[0055] A. After turning off the anti-derailment automatic control enabling switch, use the locking sensor to detect whether the spreader and the container are locked;

[0056] B. When the spreader and the container are not locked, the locking sensor has no signal output, the vehicle controller will not enter the anti-derailment automatic control program of the front stacker container, and the driver can quickly lift the boom to avoid affecting the normal operation;

[0057] C. When the spreader and the container are locked, the locking sensor outputs a signal to the vehicle controller, and the vehicle controller controls the lifting cylinder to make the boom rise slowly; when the boom is lifted slowly and the spreader is in the box When the sensor signal disappears, the length and angle sensors transmit the current boom length L and the angle A between it and ...

Embodiment 3

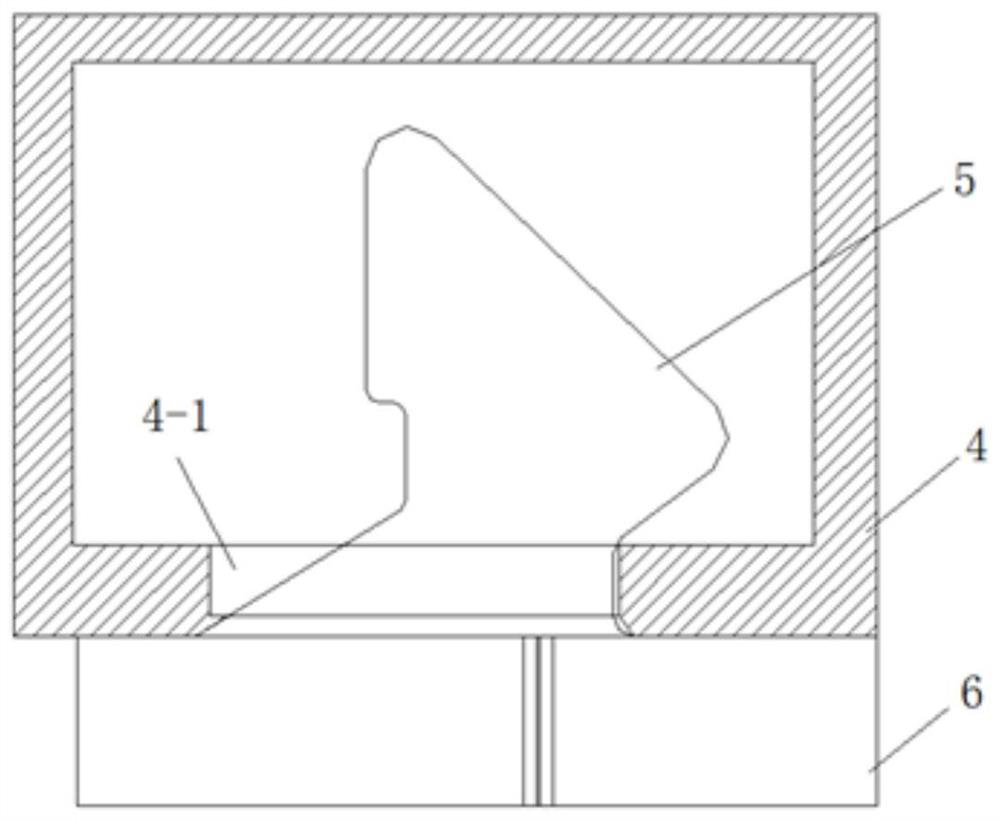

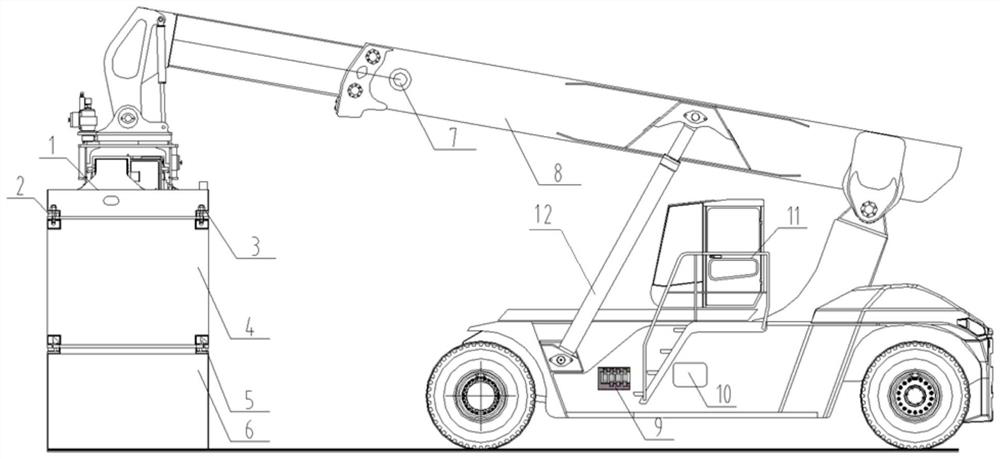

[0062] like figure 1 , 2 As shown, a front stacker container anti-derailment control system includes a vehicle controller 10, an anti-derailment enabling switch 11, a spreader 1 connected to the front end of the boom 8, and a lifting cylinder 12 for driving the boom 8 to lift. The oil inlet end of the lifting cylinder 12 is connected with a proportional solenoid valve 9 in series, and the length angle sensor 7 for detecting the length of the boom 8 and the angle between it and the horizontal line is installed on the boom 8; Proximity sensor 2 and load cell 3 are respectively installed at the lock head of the spreader, and the output ends of the length angle sensor 7, proximity sensor 2, load cell 3, and anti-derailment enabling switch 11 are all connected with the input of vehicle controller 10. The output terminal of the vehicle controller 10 is connected with the proportional solenoid valve 9 to control its opening size.

[0063] In a further solution, the proximity sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com