''Seamless'' design for rail interface

A rail and port technology, applied in the field of "seamless" rail interface design, can solve the problems of train structure damage, vibration damage, and large energy consumption, so as to reduce the probability of train derailment accidents, eliminate the conditions of frontal collision, and eliminate the frontal collision. The effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

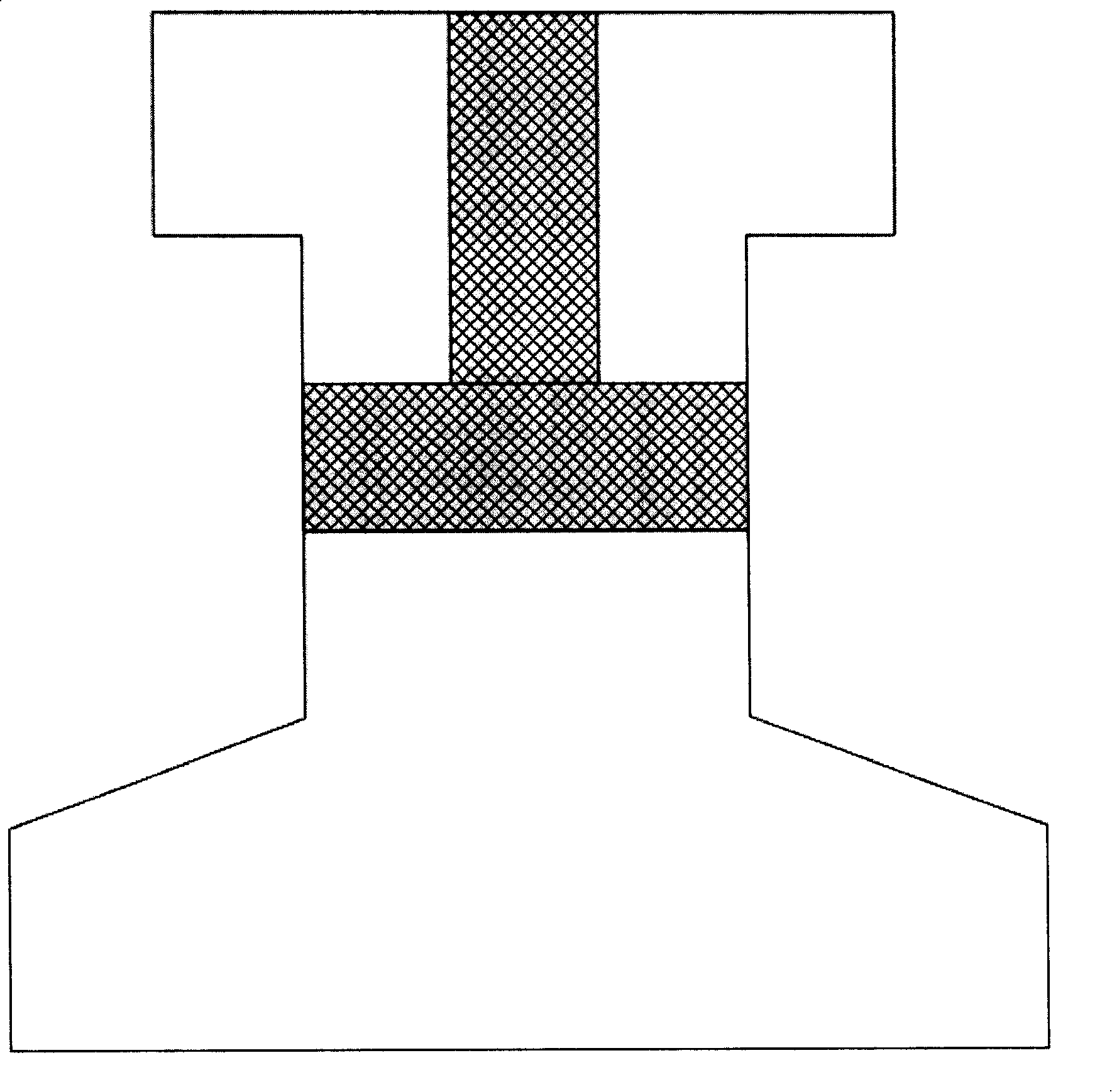

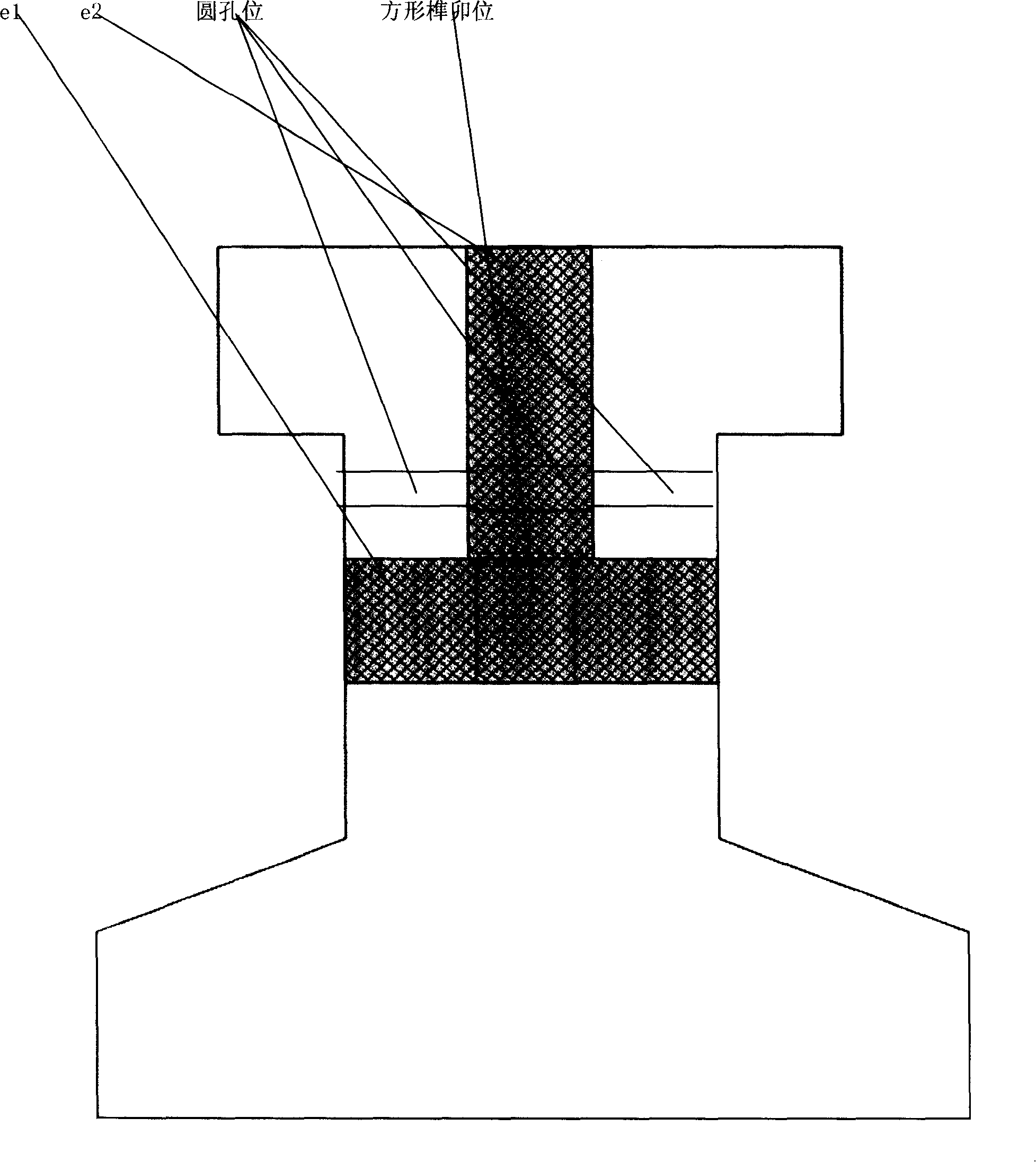

[0006] (1) As shown in Figure 1, formulate standards and prefabricate the inverted T-shaped (shaded part in the figure) mortise and tenon structure at the interface of the rails according to the standard. Divide a rail into two ends, A and B. End A protrudes 100mm inverted T-shaped mortise from the cross-section, and prefabricated 100mm inverted T-shaped tenon and groove from the cross-section at end B. When laying, the A and B ends of different rails are inverted T-shaped The mortise and tenon joints are inserted into each other and reserve space for thermal expansion and contraction in the axial direction. With such a structure, the two rails will be closely combined under the action of longitudinal and lateral forces due to the mortise and tenon structure. The relative displacement to the sub-sections eliminates the existence of absolute gaps from the perspective of the overall horizontal direction. Based on the above design, the position difference protrusions and gaps th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com