Equal-section steel concrete combined double-layer bearing plate force-transmitting anchoring structure

A technology for anchoring structures and bearing plates, applied in bridge parts, bridges, buildings, etc., can solve problems such as failure to solve the structural form, stress concentration in the steel-concrete joint section, and short stress transfer route, etc., to achieve extended design. The effect of smooth space and stress transfer route and improvement of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

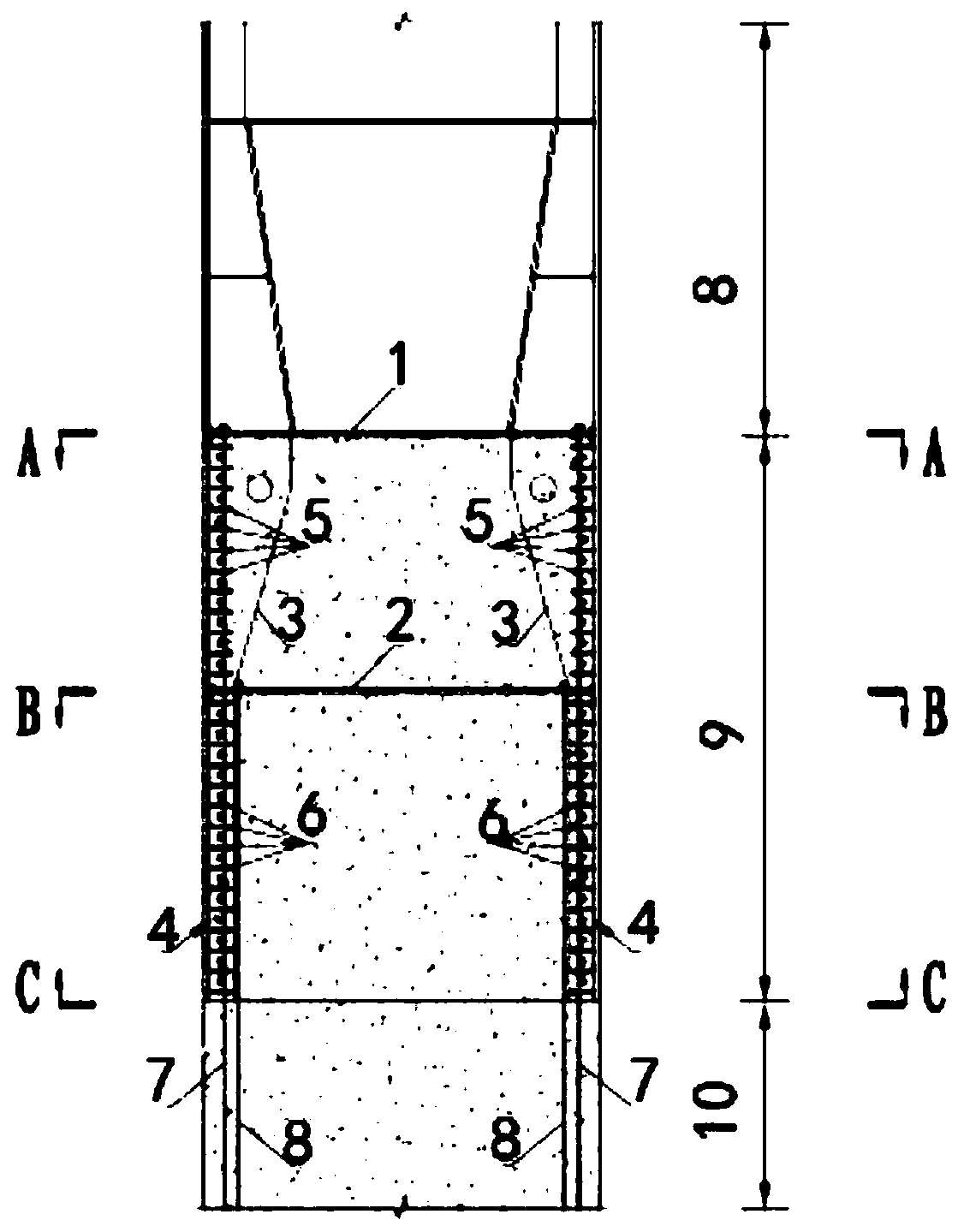

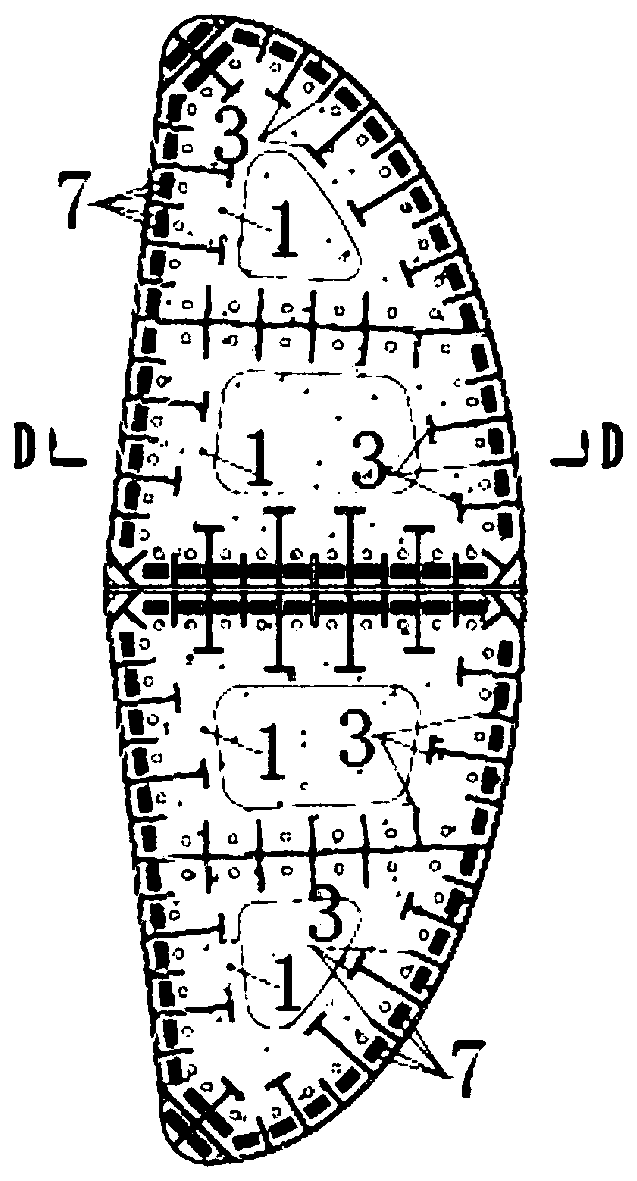

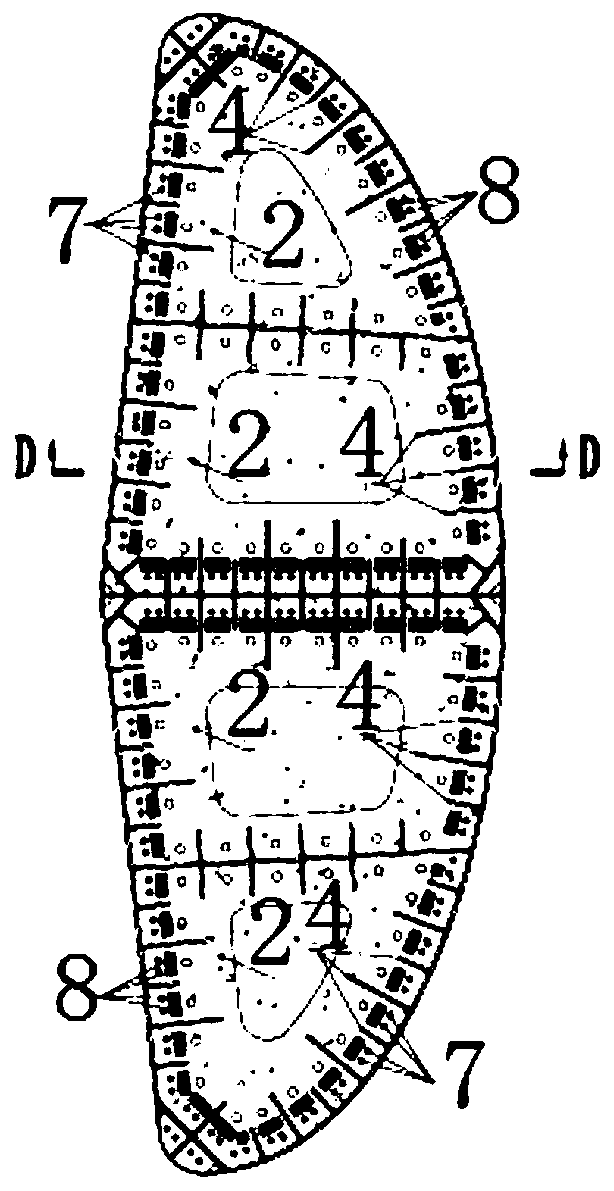

[0031] Such as figure 1 As shown, this embodiment provides a steel-concrete combined double-layer pressure-bearing plate force-transmitting anchorage structure, which is applied to the cable-stayed bridge tower. 11, wherein the steel-concrete joint section 10 is an application example of the force-transmitting anchorage structure of the steel-concrete joint with double-layer bearing plates described in this embodiment.

[0032] In this embodiment, the initial position of the steel-concrete joint section 10 (that is, at the junction with the whole steel section 9) is provided with a first layer of pressure-bearing plate 1, the steel plate thickness of which is 60 mm, and the middle part of the steel-concrete joint section 10 is provided with The second layer of pressure-bearing plate 2 has a steel plate thickness of 40mm, and concrete is poured inside the steel tower wall (steel structure wall plate) of the steel-concrete joint section 10, so that both layers of pressure-bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com