Thermal-insulation-pipe welding-forming device

A technology of welding forming and heat preservation pipes, which is applied in the direction of tubular objects, applications, household appliances, etc., to achieve the effects of smooth and uniform transportation, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

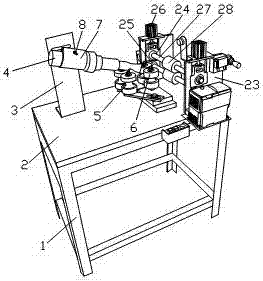

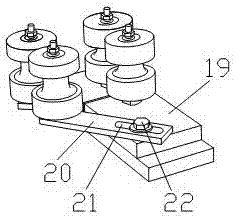

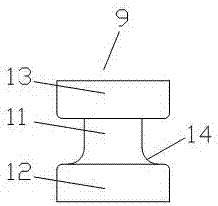

[0020] like Figure 1 to Figure 4 As shown, the present invention provides a heat preservation pipe welding forming device, comprising a frame 1, a platen 2 on the frame 1, a welding forming device and an electrical system arranged on the platen 2; The direction in which the tube travels is sequentially provided with: a bracket 3 on which a welding torch 4 is fixed, a first roller group 5, a second roller group 6, and a traction part, and the first roller group 5 and the second roller group 6 can realize spacing adjustment; The welding port of the welding torch 4 is aligned with the matching position of the second roller set, and the welding torch 4 is connected to the bracket 3 through a movable support frame.

[0021] The movable support frame includes a cylinder 7 with an opening, two support rods welded on the cylinder 7 and a locking mechanism 8 at the opening of the cylinder 7, and the welding torch 4 is inserted in the cylinder 7 And lock by locking mechanism 8; Descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com