Assembly type hydraulic stepping machine used in pit unloading process

An assembled, stepper technology, applied in the direction of conveyors, loading/unloading, conveyor objects, etc., can solve problems such as bulking blockage, affecting production efficiency, and limited carrying capacity of frequency conversion belt conveyors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

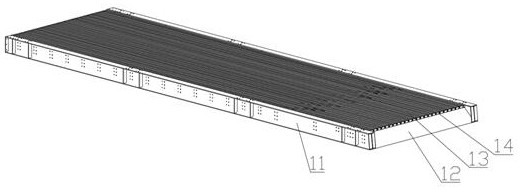

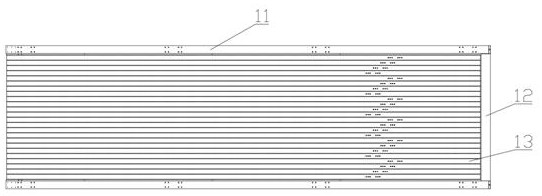

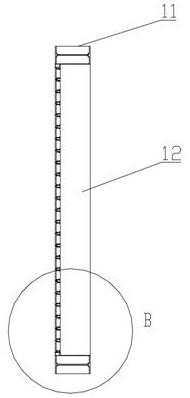

[0034] Such as Figure 1-8 As shown, an assembled hydraulic stepper used in the pit unloading process, including a main body and a drive system;

[0035] Wherein the main part includes two main beams 11, end flow plate 12, movable plate 13, plastic cushion block 14, bottom beam 15, bottom cable stay 16 and oil cylinder installation beam 17, and the connection ends between two main beams 11 The drool board 12 forms the main frame of the hydraulic stepping machine. The lower part of the main beam 11 is provided with a plurality of bottom beams 15. Both the main beam 11 and the bottom beam 15 are assembled by sheet metal bending parts through bolt connection. There are bottom slanting 16, bottom crossbeam 15 and the upper part of the end flow plate 12 are provided with several plastic spacers 14, which are fixedly connected to the bottom crossb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com