Piston assembly for linear compressor

A linear compressor and piston assembly technology, applied in the field of compressors, can solve problems such as spring failure, increased clearance volume, and fracture of the joint of the suction valve plate, and achieve a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

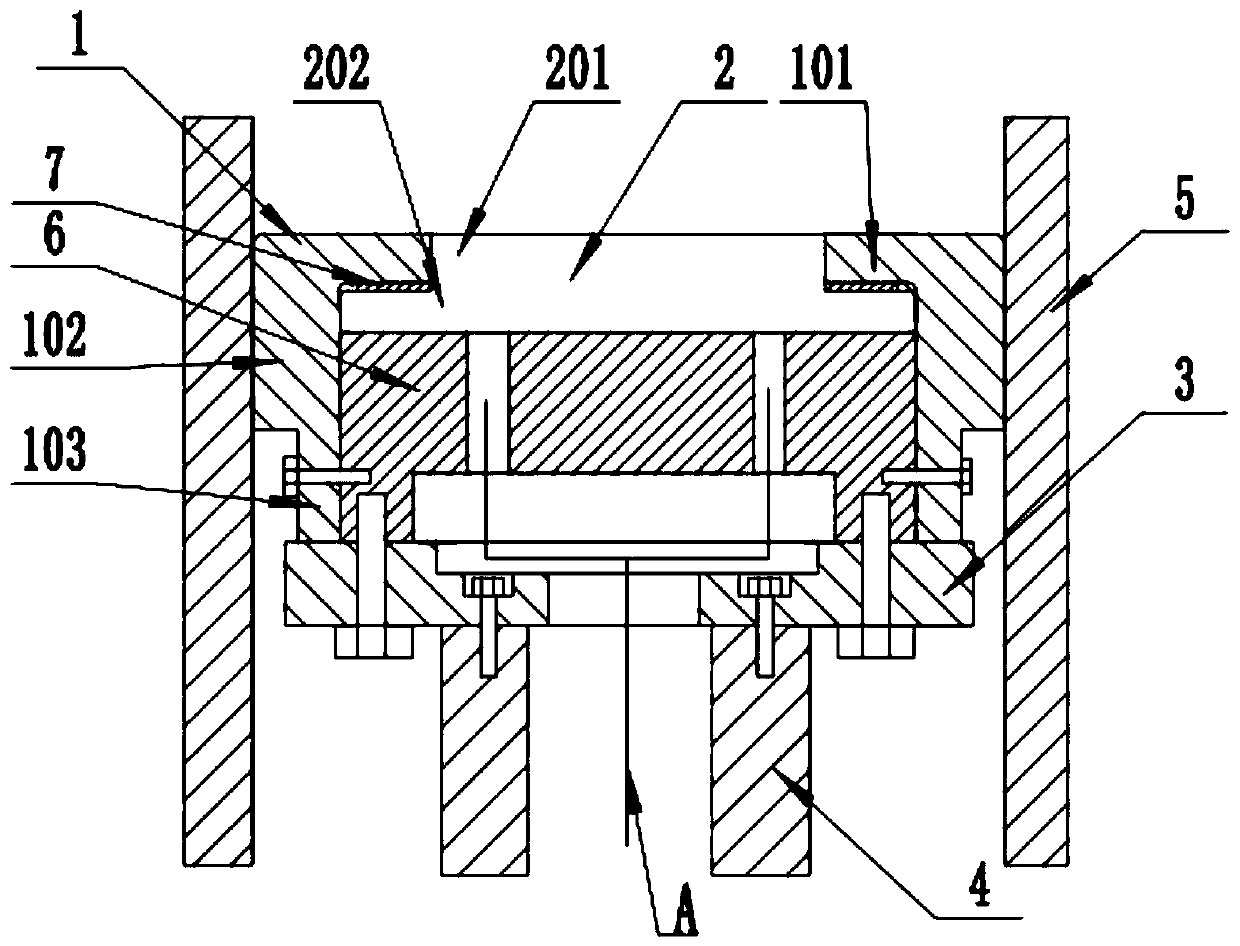

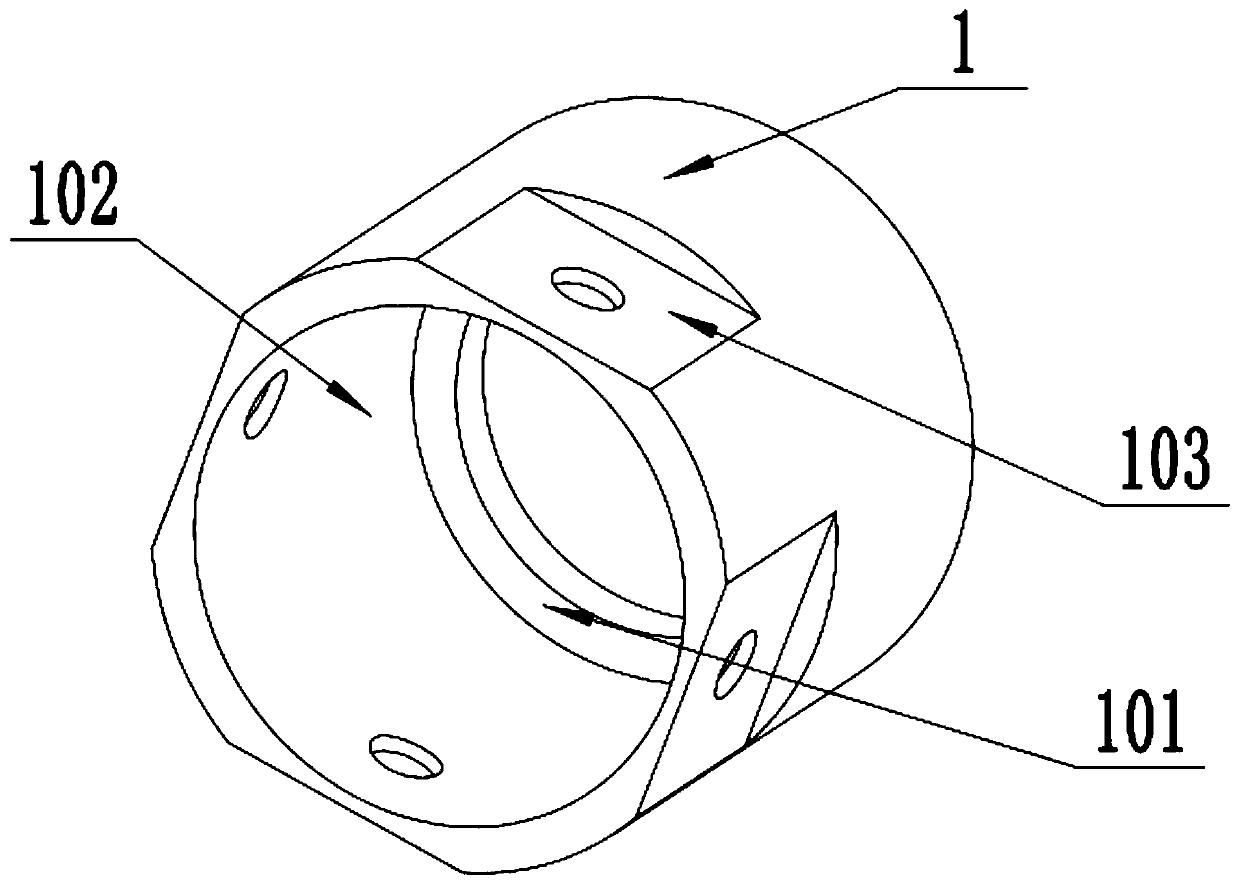

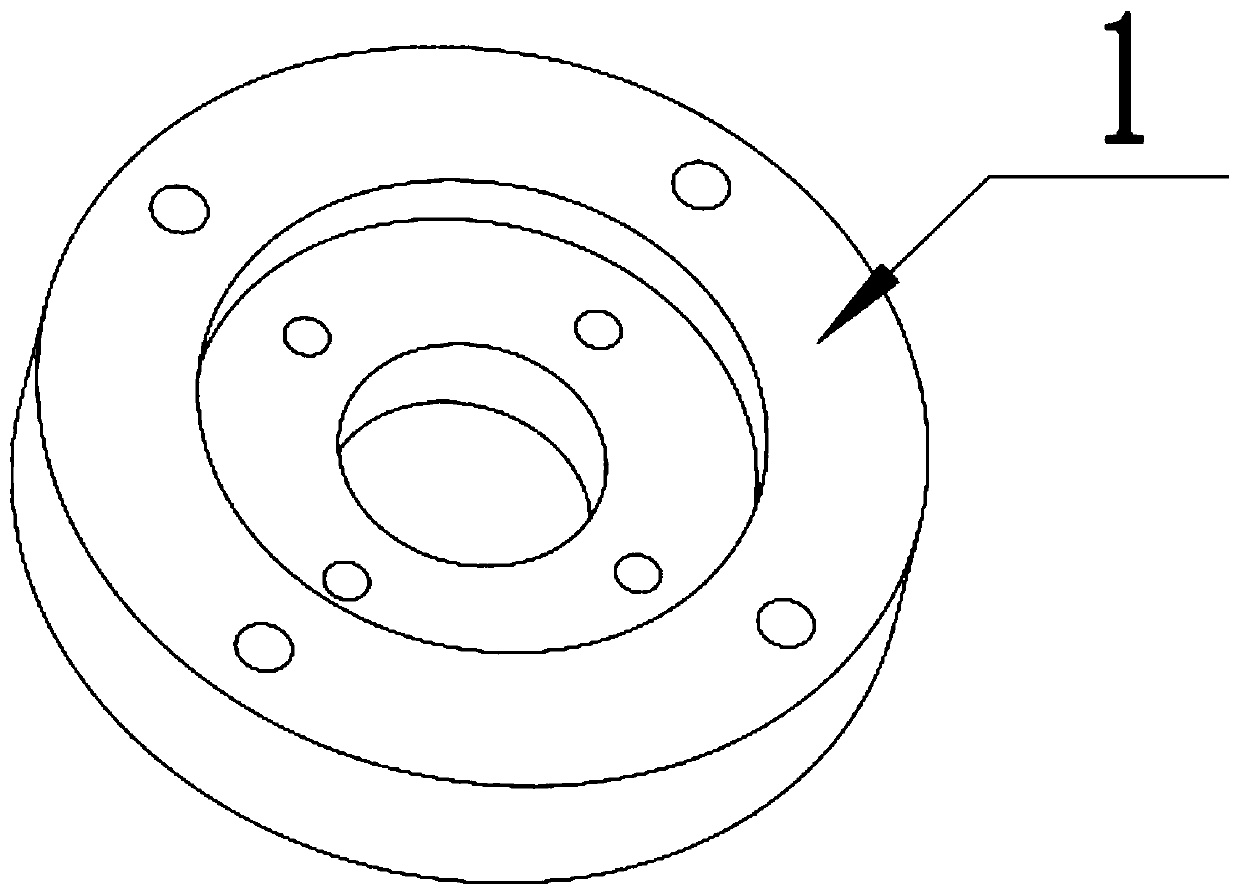

[0023] Such as Figure 1~4 As shown, a piston assembly for a linear compressor includes a suction valve plate 2, a connecting pipe 4, a piston cover 1, a connecting plate 3, and an intermediate block 6. The piston cover 1 is a hollow cylindrical structure, and one end of the piston cover 1 A flange 101 is arranged radially inwardly at the end of the piston cover 1. There are 4 evenly distributed planes 103 for setting threaded through holes on the outer wall of the piston cover 1. There is a threaded through hole on each plane. The suction valve plate 2 The shape is "convex", the part of the suction valve plate 2 with a small diameter is the first cylinder 201, the part with a large diameter of the suction valve plate 2 is the second cylinder 202, the suction valve plate 2 is arranged in the piston cover 1, and the suction The first cylinder 201 of the gas valve plate 2 is embedded in the flange 101 of the piston cover 1, and the end face of the first cylinder 201 of the sucti...

Embodiment 2

[0026] Such as Figure 1~4 As shown, this embodiment is further limited on the basis of Embodiment 1, the shape of the middle block 6 is cylindrical, one end of the middle block 6 is provided with a circular groove, and the other end of the middle block 6 is provided with 6 uniform Distributed through holes, and the through holes communicate with the groove at one end of the middle block 6, and the outer wall of the middle block 6 is provided with four evenly distributed internal thread holes, the internal thread holes are close to the end of the groove, and the internal thread The hole axis is collinear with the threaded through-hole axis on plane 103 . The depth of the groove is 10-20mm, and if the depth is less than 10mm, it is not conducive to the circulation of refrigerant gas. If the depth is greater than 20mm, the size of the middle block is too large, which is of no benefit to the entire piston assembly and may reduce the stroke . Further, a protrusion is provided on...

Embodiment 3

[0029] Such as Figure 1~4 , this embodiment is further limited on the basis of Embodiment 1, the connecting plate 3 and the connecting pipe 4 are threaded, the connecting plate 3 and the middle block 6 are threaded, and the threaded connections in this embodiment are all Bolts are used for connection, and spring washers are used in conjunction with the bolts. In addition, there is an annular washer at the connection between the connecting plate 3 and the middle block 6 to prevent refrigerant leakage. The shape of the connecting plate 3 is a circular plate, the center of the connecting plate 3 is provided with a stepped through hole, the peripheral edge of the connecting plate 3 is provided with 4 evenly distributed threaded through holes, and the step of the connecting plate 3 is provided with 4 evenly distributed threaded through holes. threaded through holes.

[0030] Furthermore, the suction valve plate 2 adopts a combination of a cylinder at the top and a truncated cone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com