Dryer based on methanol heating

A dryer and methanol technology, which is applied to dryers, drying, lighting and heating equipment, etc., can solve the problems of high working cost and large power consumption, and achieve low production cost, lightening power consumption and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

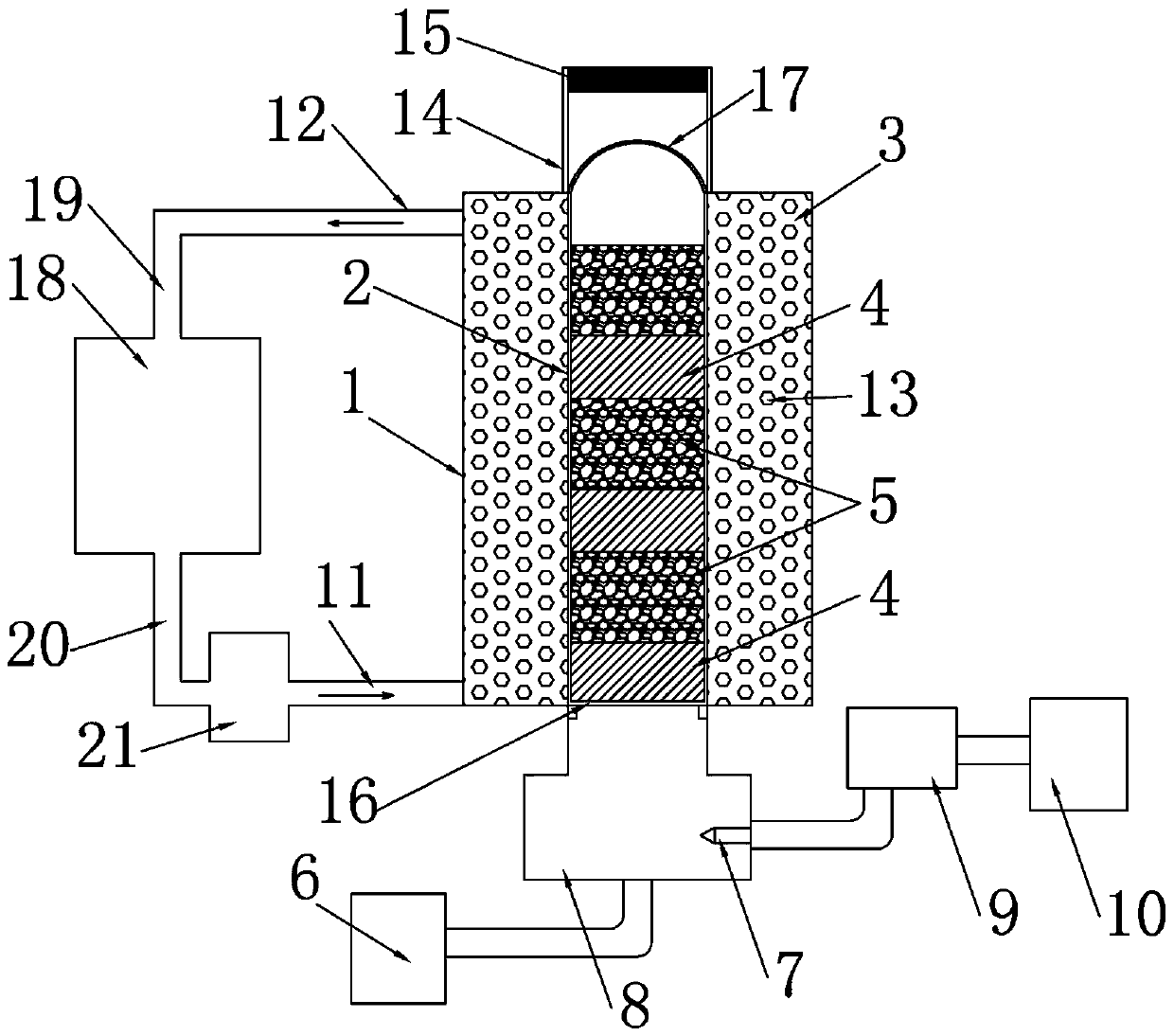

[0019] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A dryer based on methanol heating, characterized in that it includes a dryer body and a methanol heater;

[0020] Wherein, the methanol heater includes a heat exchange cylinder 1, the center of the heat exchange cylinder 1 is provided with a heating tube 2, a heat exchange cavity 3 is formed between the heating tube 2 and the outer wall of the heat exchange cylinder 1, and the upper and lower ends of the heat exchange cavity 3 are An air inlet 11 and an air outlet 12 are respectively provided, and the heat exchange medium enters and exits from the heat exchange port to exchange heat with the heat exchange chamber 3;

[0021] The heating tube 2 is stacked with several layers of catalytic cakes 4 and heat storage cakes 5, and the end faces of the catalytic cakes 4 and heat storage cakes 5 are provided with a number of ventilation holes, and the catalytic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com