Penetrating laser thickness gauge

A laser thickness measurement and penetrating technology, applied in the field of optical measurement, can solve the problems of large data difference, high production cost and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

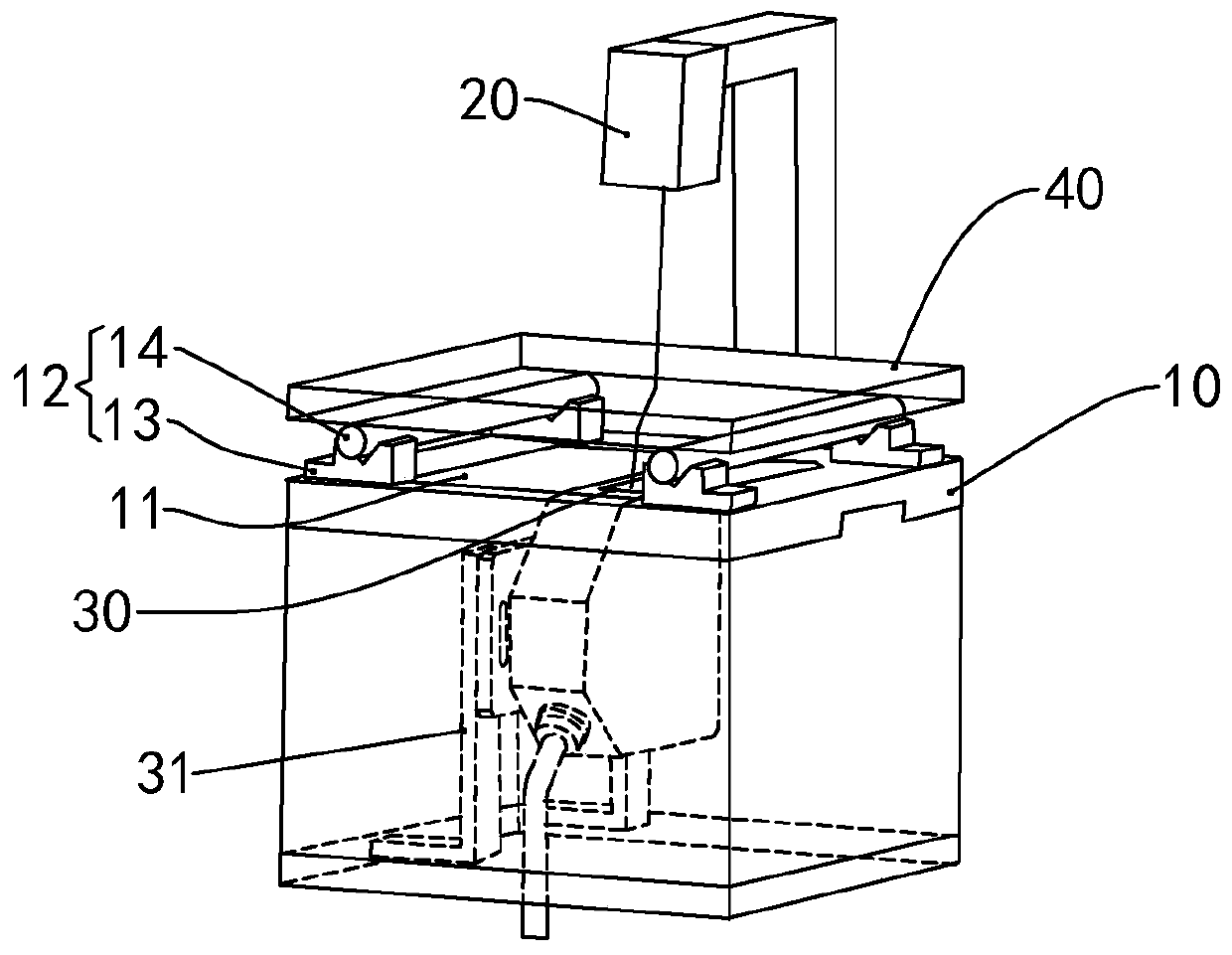

[0017] Such as figure 1 As shown, the penetrating laser thickness gauge of this embodiment includes a workbench 10 , a laser emitting device 20 and a CCD detection device 30 .

[0018] The workbench 10 is used for placing the transparent DUT 40 . Specifically in this embodiment, the workbench 10 is set horizontally, the workbench 10 is provided with a notch 11 and supports 12 arranged around the notch 11, the number of the supports 12 is two, and the two supports 12 are symmetrically arranged on Notch 11 both sides. The support 12 includes a bracket 13 and a roller 14 arranged on the bracket 13, the bracket 13 is arranged at both ends of the roller 14, the bracket 13 is fixed on the workbench 11, and the transparent DUT 40 is placed on the roller 14 on. The supporting member 12 is used to support the transparent DUT 40 , and the setting of the roller 14 helps to avoid scratching the transparent DUT 40 when the transparent DUT 40 moves.

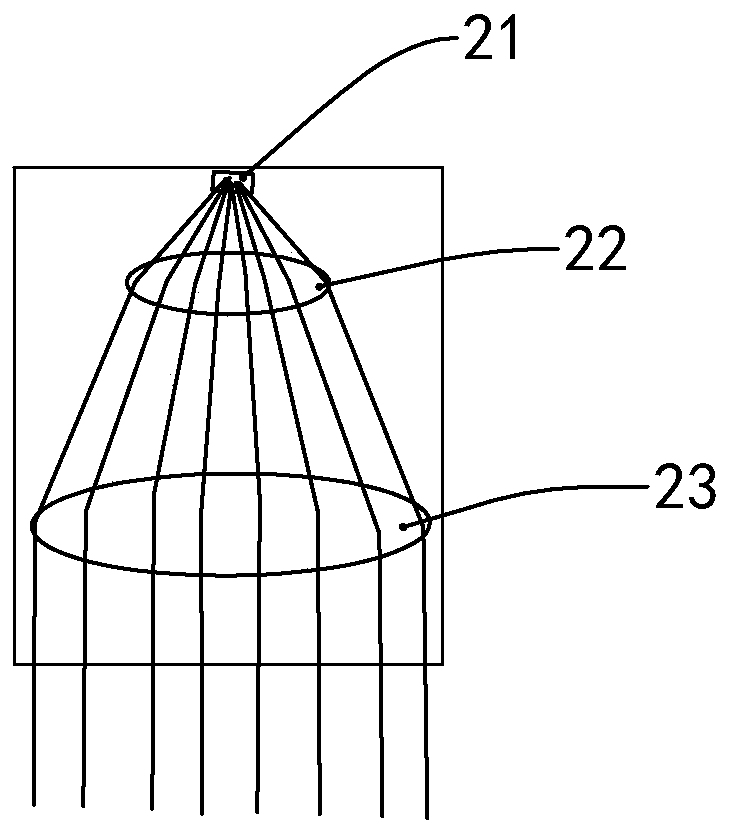

[0019] The laser emitting device 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com