High-temperature superconducting motor and low-temperature holding container thereof

A technology of low temperature maintenance and high temperature superconductivity, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of ineffective transmission of stator electromagnetic force, reduced motor performance, and excessive air gap, so as to ensure safe and stable operation, Cooling is simple and low, and the effect of sealing is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

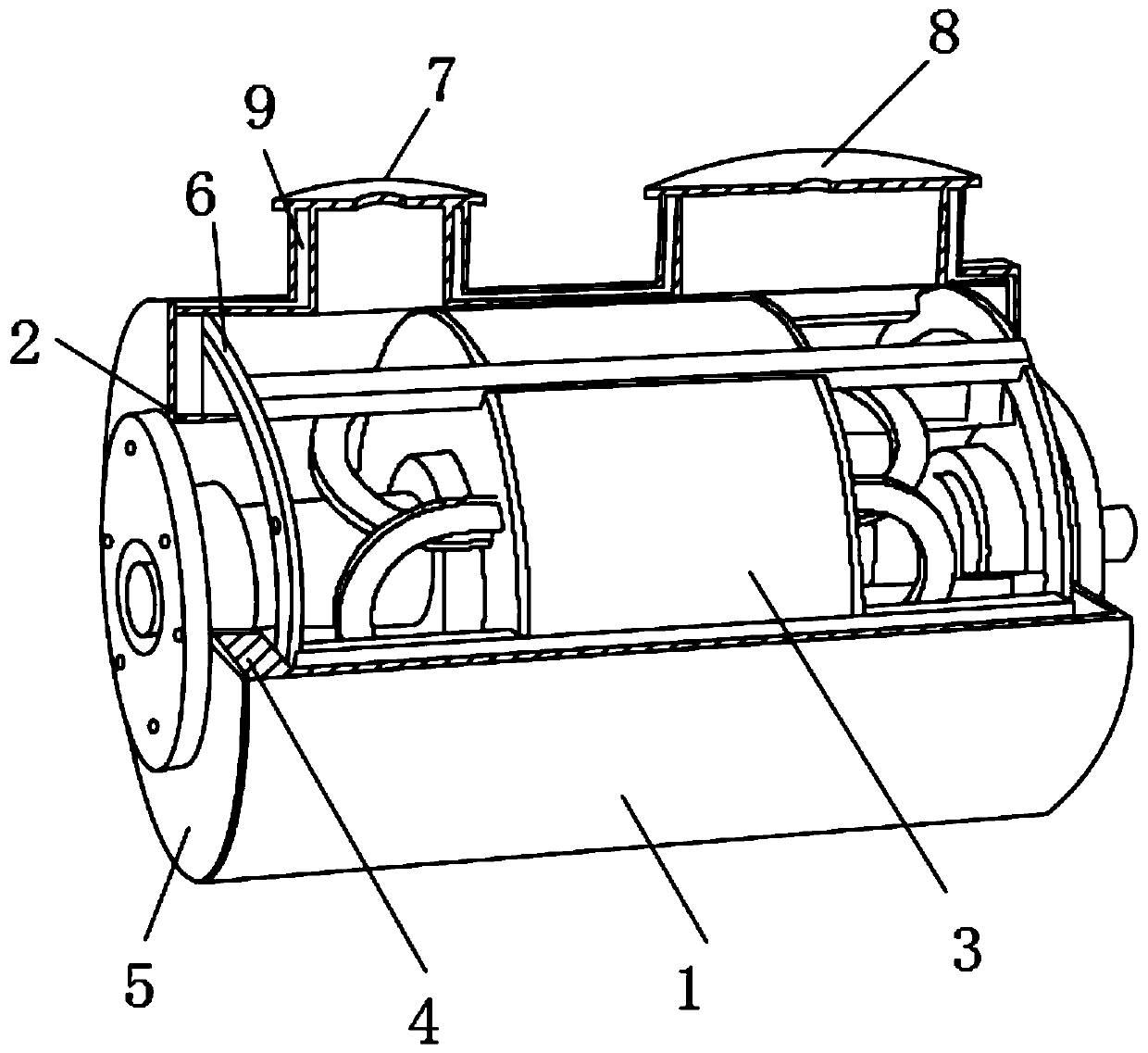

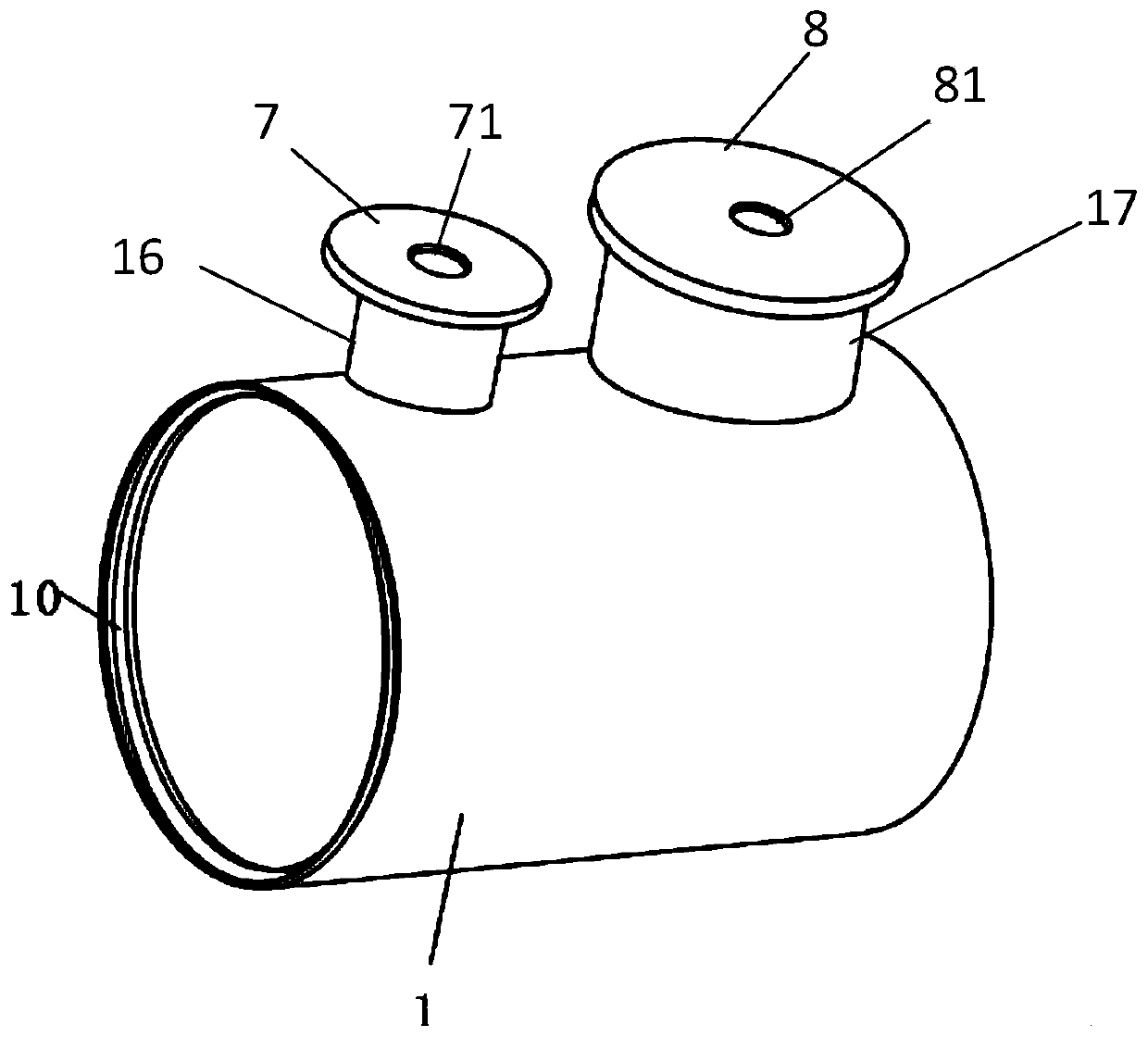

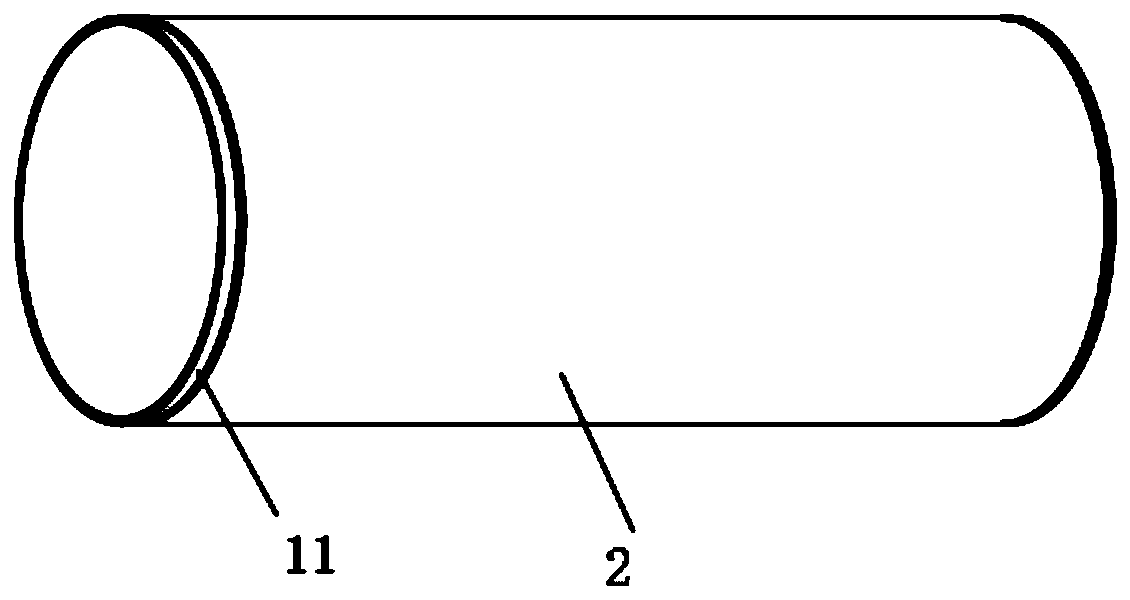

[0027] refer to figure 1 , figure 2 , image 3 and Figure 6 As shown, the present invention provides a low-temperature holding container for high-temperature superconducting motors. The low-temperature holding container includes an outer cylinder 1 and an inner cylinder 2. The accommodating cavity, the inner cylinder 2 has a second accommodating cavity for accommodating the rotor of the high-temperature superconducting motor, the inner cylinder 2 is set in the first accommodating cavity, and the outer cylinder 1 is opened at both ends and sealed with the inner cylinder 2 through a sealing mechanism , The annular area between the inner cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com