Laser welding method

A laser welding and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as insignificant deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

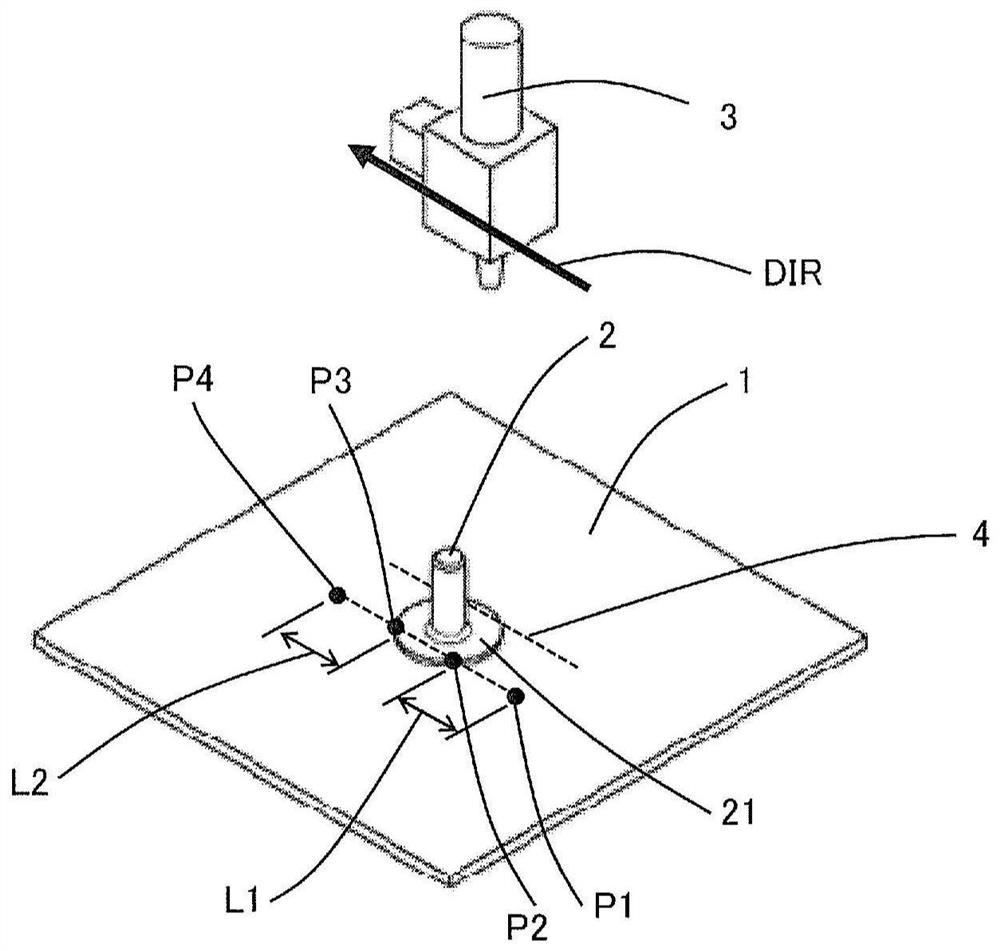

[0035] In Embodiment 1, an embodiment in which small parts such as studs are laser-bonded to a decorative material will be described. figure 1 It is a perspective view for demonstrating the laser welding method of the decoration material which concerns on Embodiment 1 of this invention. More specifically, the figure 1 It is a perspective view which shows the state which welds the stud 2 fixed to the decoration material 1 by the jig|tool, moving a laser welding head.

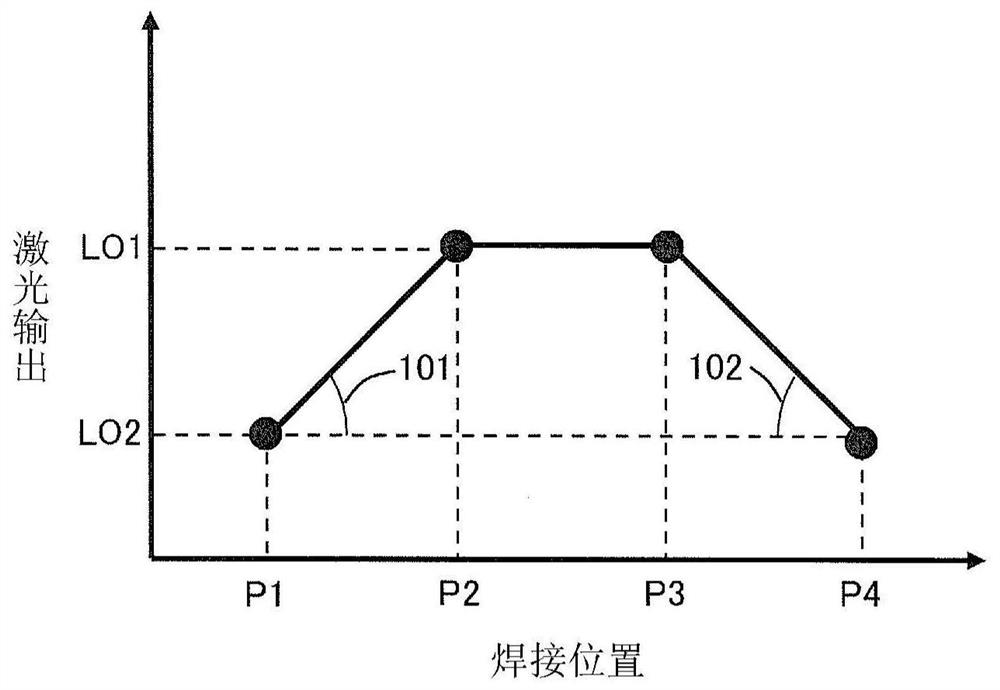

[0036] also, figure 2 It is a figure which shows the relationship of a welding position and a laser output when the laser welding method of the decoration material which concerns on Embodiment 1 of this invention is applied. use these figure 1 , figure 2 , and the laser welding method of the decorative material according to the first embodiment will be described in detail.

[0037] First, the laser welding head 3 moves to the welding start position P1 on the welding line 4 . The distance L1 between the we...

Embodiment approach 2

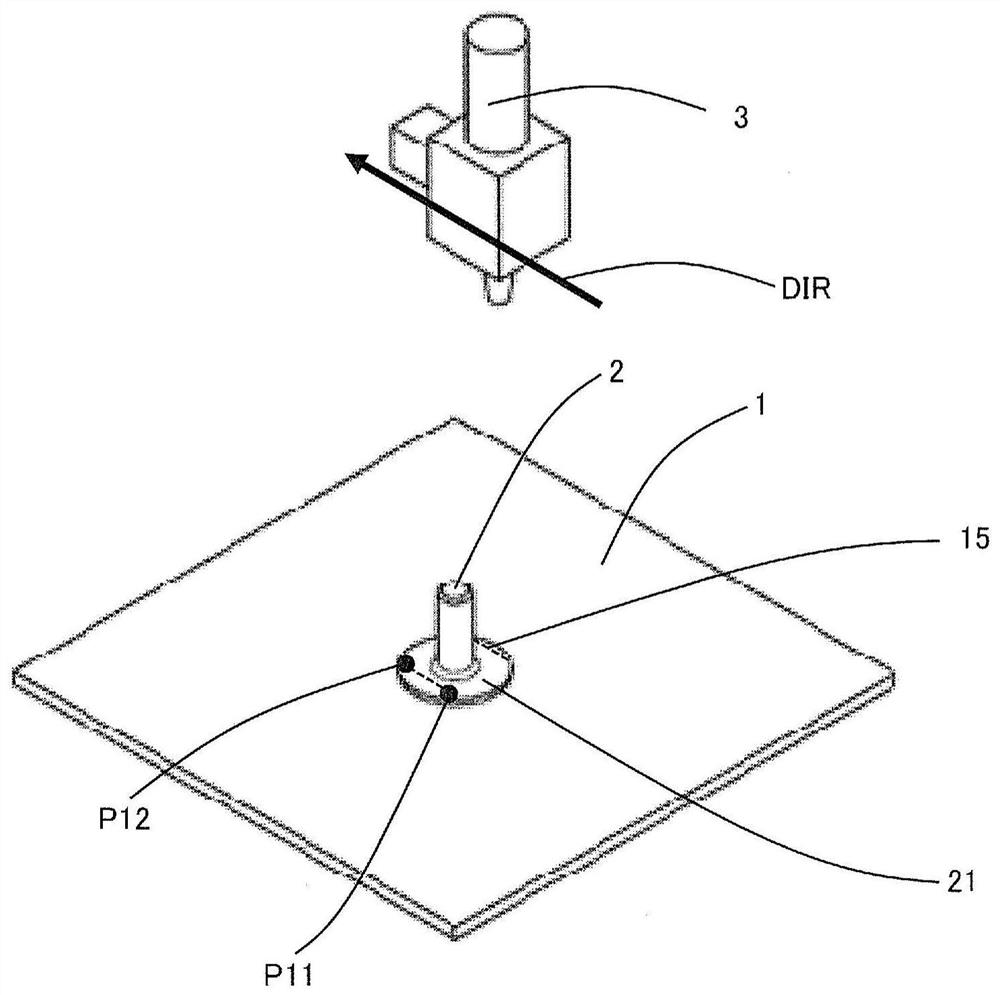

[0050] In Embodiment 2, the case where the first welding is performed in the flange 21, the size of the deformation is measured, and the value of the main laser output is set to an appropriate value based on the measurement result, is used as the second welding. For the second welding, the welding process described in the first embodiment above is carried out.

[0051] image 3 It is a perspective view for demonstrating the 1st welding of the laser welding method of the decorative material concerning Embodiment 2 of this invention. also, Figure 4 It is a perspective view for demonstrating the 2nd welding of the laser welding method of the decoration material which concerns on Embodiment 2 of this invention.

[0052] and, Figure 5 It is a figure which shows the relationship of a welding position and a laser output when the laser welding method of the decoration material which concerns on Embodiment 2 of this invention is applied. use these Figure 3 ~ Figure 5 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com