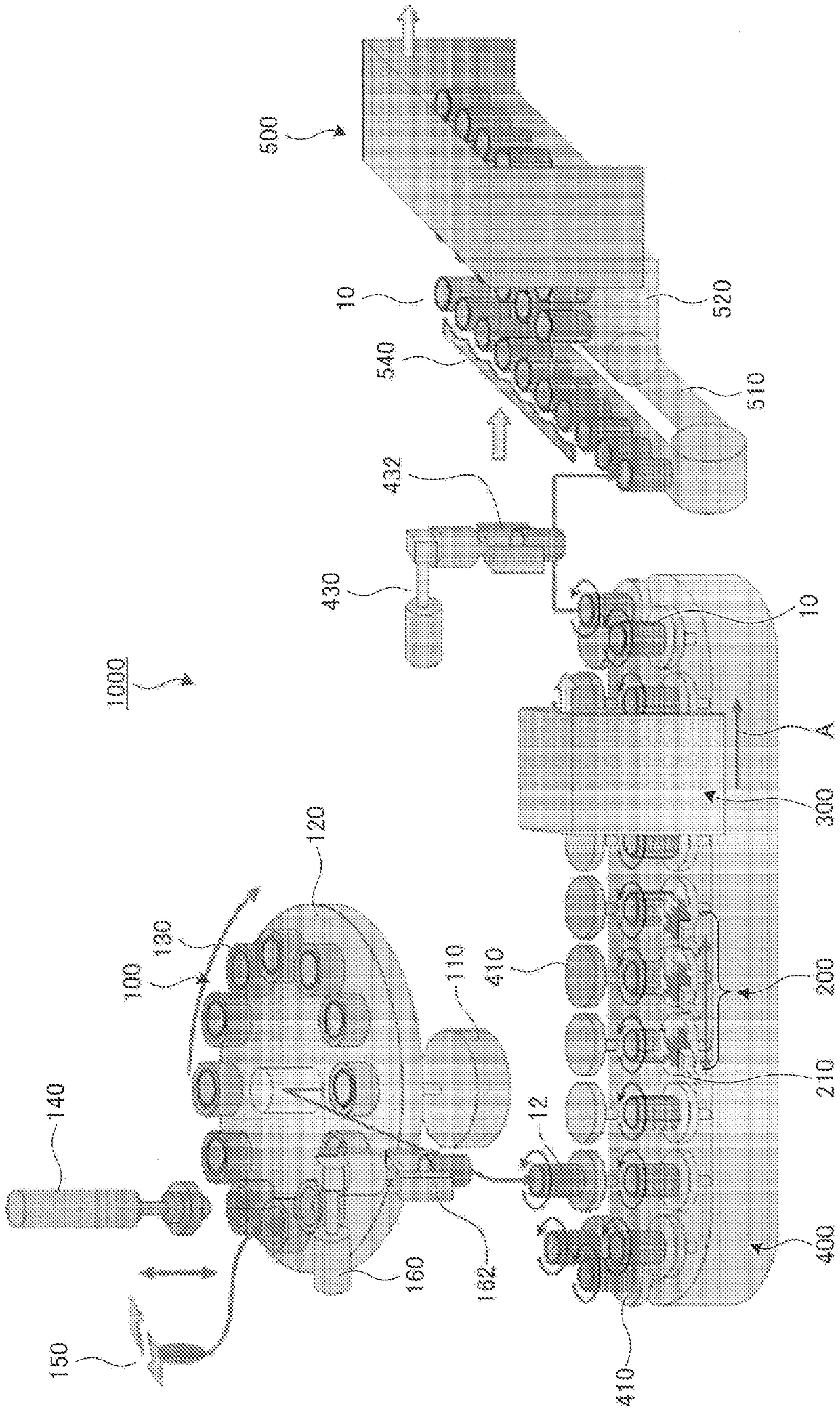

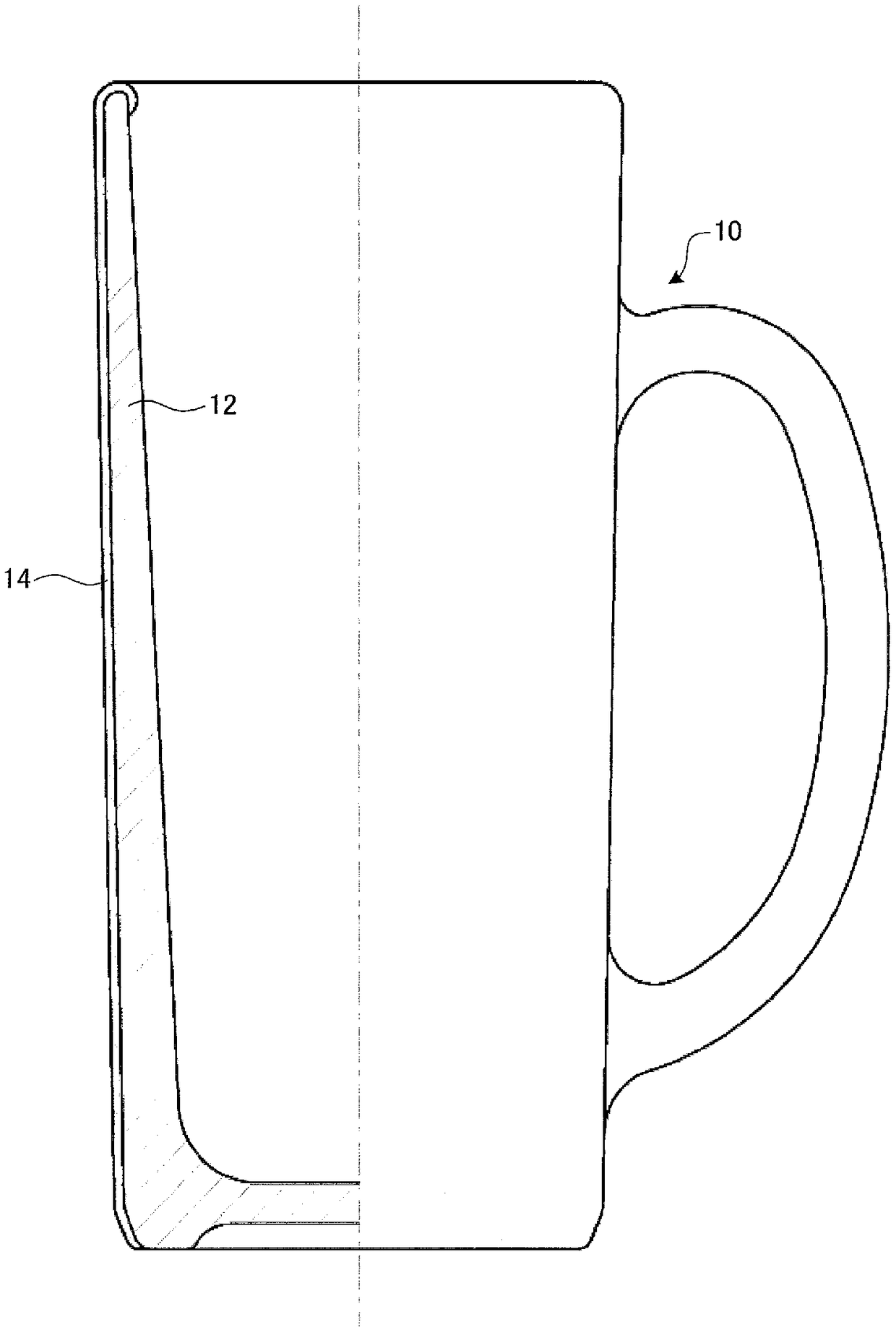

Glass container, and method and device for manufacturing same

一种玻璃容器、制造方法的技术,应用在玻璃制造设备、容器、家用容器等方向,能够解决得不到耐损伤性、得不到覆膜硬度和划痕强度、得不到耐碱性等问题,达到减少破损、耐碱性优异、防止损伤的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10

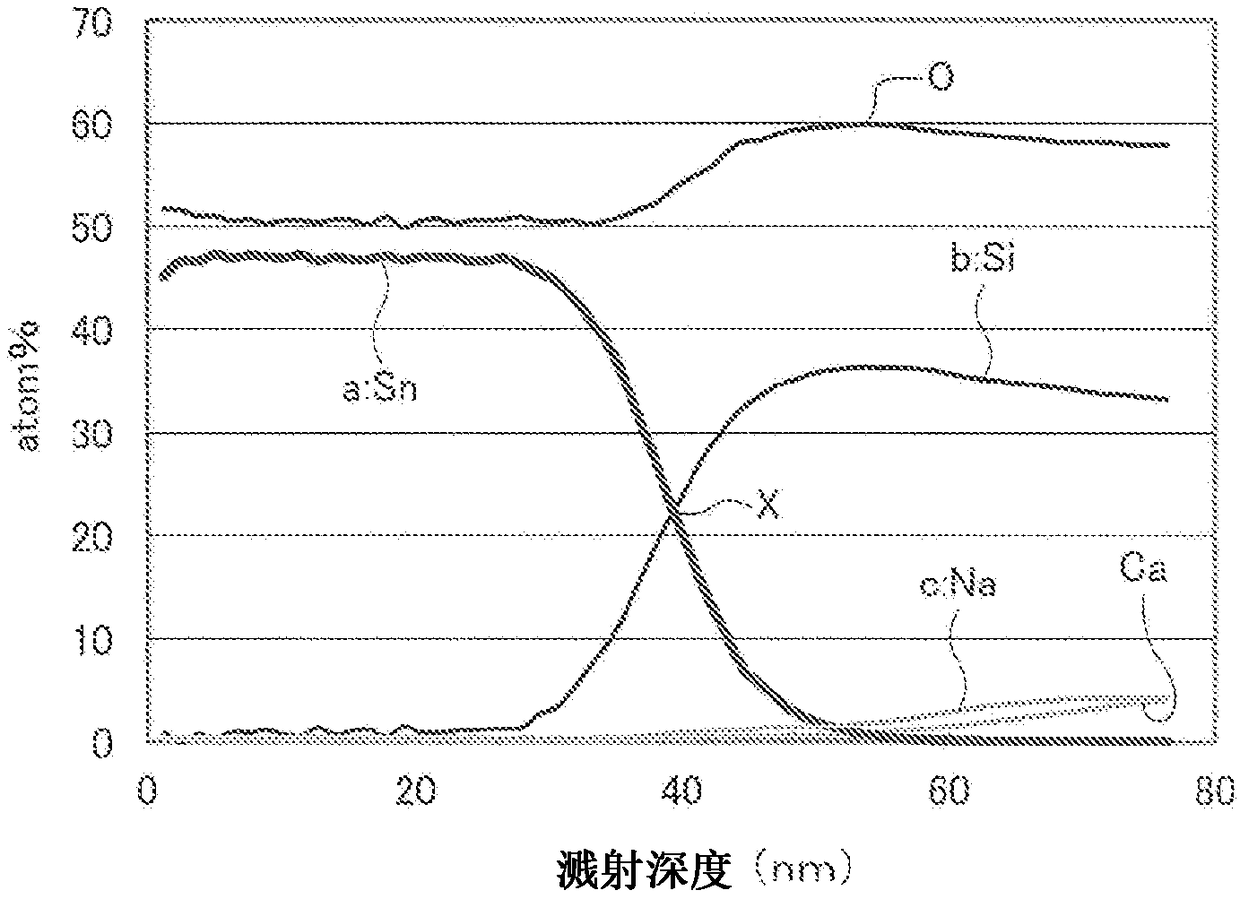

[0133] 3.2. XPS analysis (embodiment 10, comparative example 13)

[0134] (1) Formation of samples

[0135] The main body of the container (the barrel of the beer mug) was formed by the forming device 100 using soda lime glass. Next, in a state where the container body is kept at 700° C., the heating device (burner 210) uses an oxygen flame to perform heat treatment at a flame temperature of 1420° C. and a flame treatment time of 1 second to make the outer surface area of the container body of sodium detachment. Next, using the film forming apparatus 300, a film of tin oxide with a film thickness of 40 nm was formed on the outer surface of the container main body at a source gas temperature of 140° C. and a film forming time of 2 seconds. Thus a sample of Example 10 was obtained.

[0136] A sample of Comparative Example 13 was obtained in the same manner as in Example 10 except that flame treatment was not performed. In addition, in this case, the temperature of the cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com