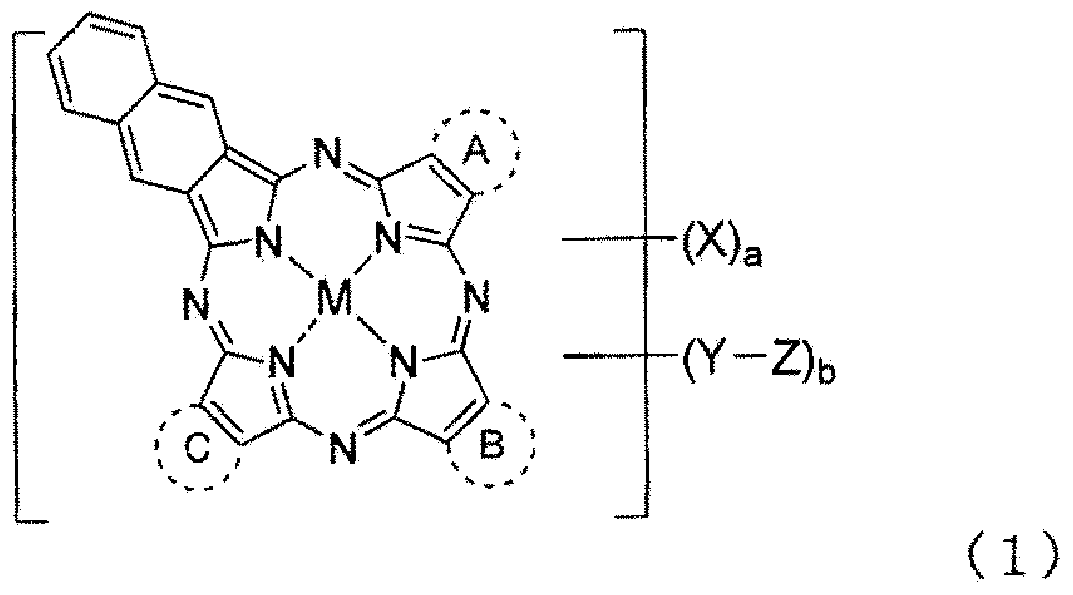

Porphyrazine dye, and application therefor

A technology of porphyrazine and pigment, applied in the directions of porphine/acrphine, azo dyes, organic dyes, etc., can solve the problems of strong yellow tone, damage to aesthetics, difficult to use, etc., and achieves suppression of yellow tone without damaging aesthetics The effect of high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

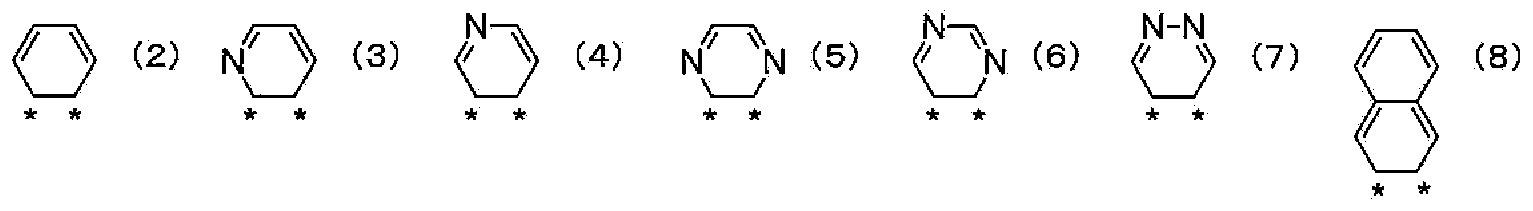

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1 (above-mentioned compound example No.1)

[0071] Add 3.0 parts of phthalic anhydride, 11.9 parts of naphthalic anhydride, 29 parts of urea, 0.40 parts of ammonium molybdate and 3.5 parts of vanadyl (V) chloride to 120 parts of sulfolane, and raise the temperature of the resulting composition to 200°C , reacted at this temperature for 11 hours. After the reaction was terminated, the reaction liquid was cooled to 65° C., 100 parts of N,N-dimethylformamide (DMF) was added, and a solid was separated and separated by filtration. The obtained solid was washed with 50 parts of DMF to obtain 20.3 parts of a wet cake. The obtained wet cake was added to 100 parts of DMF, the obtained composition was heated up to 80 degreeC, and it stirred at this temperature for 2 hours. The precipitated solid was separated by filtration and washed with 200 parts of water to obtain 18.9 parts of a wet cake. The obtained wet cake was added to 150 parts of water, the obtained compos...

Embodiment 2

[0072] Embodiment 2 (above-mentioned compound example No.2)

[0073] Except changing 3.0 parts of phthalic anhydrides in Example 1 to 5.9 parts, and changing 11.9 parts of naphthalic anhydrides to 7.9 parts, it carried out similarly to Example 1, and obtained 12.1 parts of said compound example No. 2. The maximum absorption wavelengths of this compound in concentrated sulfuric acid are 951nm, 882nm and 815nm.

Embodiment 3

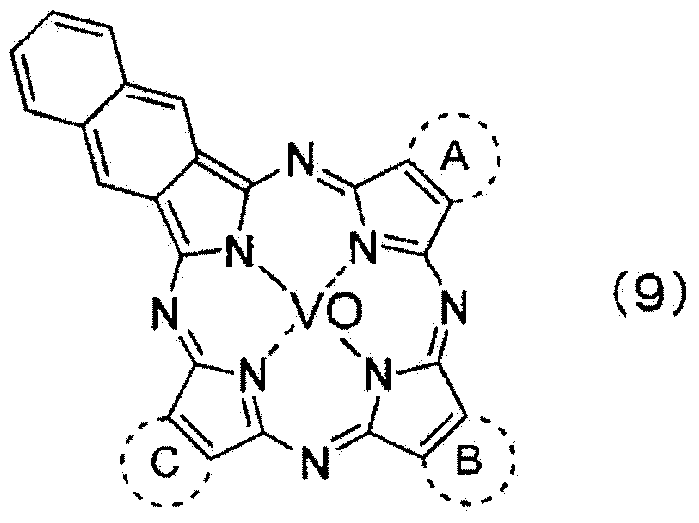

[0074] Embodiment 3 (above-mentioned compound example No.9)

[0075]Add 3.3 parts of 3,4-pyridinedicarboxylic acid, 7.9 parts of naphthalene dicarboxylic anhydride, 29 parts of urea, 0.40 parts of ammonium molybdate, and 3.5 parts of vanadyl (V) chloride to 120 parts of sulfolane, and raise the temperature of the resulting composition to 200° C., and reacted at this temperature for 11 hours. After the reaction was terminated, the reaction liquid was cooled to 65° C., 100 parts of N,N-dimethylformamide (DMF) was added, and a solid was separated and separated by filtration. The obtained solid was washed with 200 parts of 80° C. DMF to obtain 20.3 parts of a wet cake. The obtained wet cake was added to 100 parts of DMF, the obtained composition was heated up to 80 degreeC, and it stirred at this temperature for 2 hours. The precipitated solid was separated by filtration and washed with 200 parts of water to obtain 40.1 parts of a wet cake. The obtained wet cake was added to 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com